For many years attempts have been made by the industry experts to produce an elastic spandex yarn using a similar process by melt spinning TPU polymers.

We all know that Dry spinning is the most traditional and common way of producing spandex. However, one of the major drawbacks of this method is the heavy investment required in construction of a commercial-scale production plant of, for example, 3000 to 5000 tons per year. At a 40- denier average, the overall investment is in the range of US$ 40 million to US$ 50 million which is quite high. The same is true for constructing a wet-process plant. Moreover, dry and wet spinning also involve dealing with a toxic solvent recovery process and, in the case of the dry process, traces of the solvent remain in the final yarn produced. In the melt spinning method, no solvent is involved.

The preparation process for polymer in both dry and wet spinning start by making the pre-polymer, the same used in melt spinning, and sometimes called a crosslinker. Wet-process plants are only economical in producing coarser yarns of 400 denier and above, due to the limited underwater spinning speeds of a maximum of 200 meters/min.

Building on the understanding of polymer preparation used in both dry and wet spinning, which involves creating a pre-polymer similar to that in melt spinning, it is important to note the distinctions in the melt-spinning process. Wet-process plants, typically economical only for producing coarser yarns of 400 denier and above due to underwater spinning speeds capped at 200 meters per minute, contrast sharply with the capabilities of melt spinning. The melt-spinning process, instrumental in producing high-quality spandex yarns, encompasses several crucial steps that define the properties of the final product.

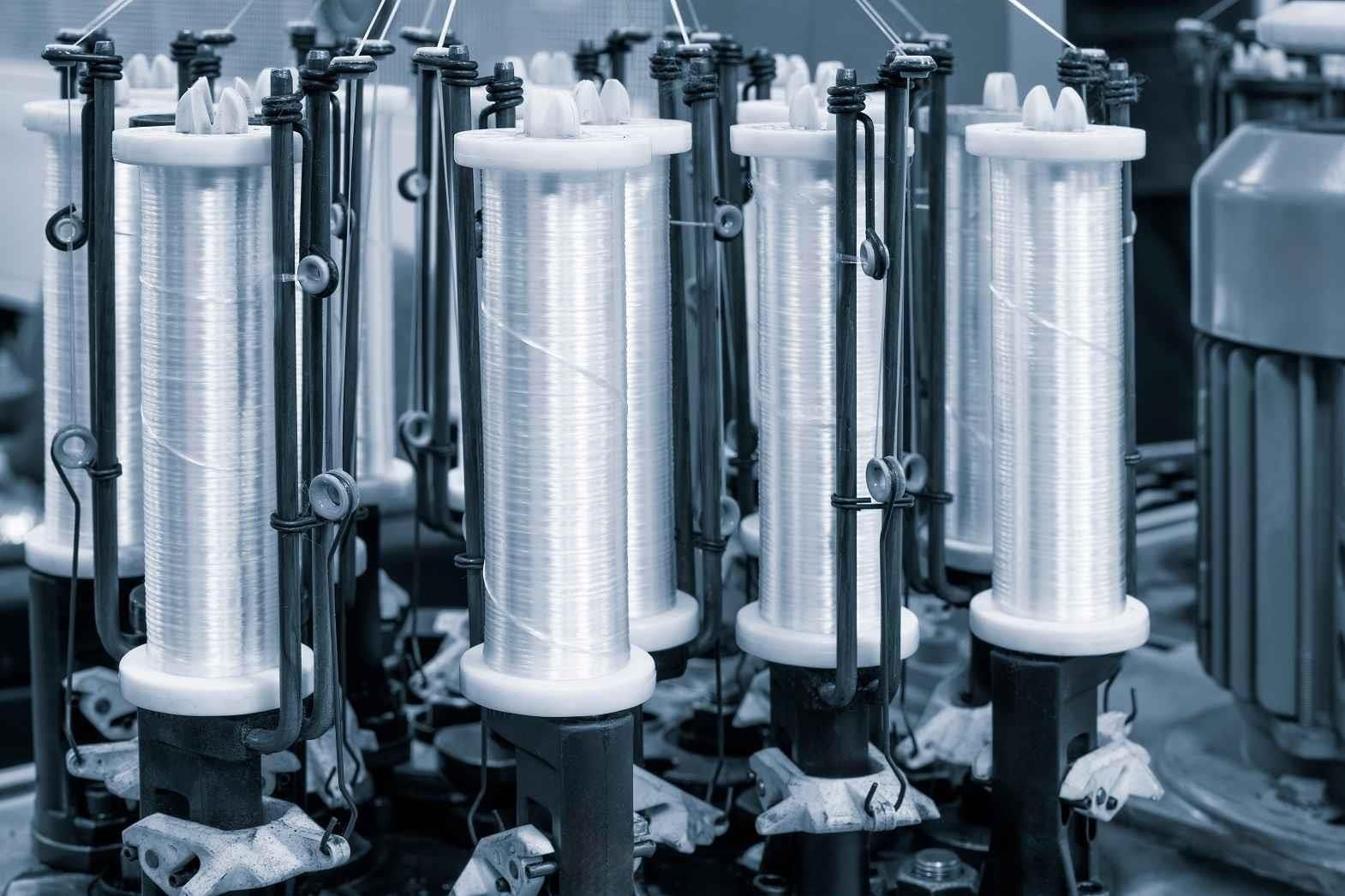

In this process, the polymer material, usually a segmented polyurethane, is first melted and then extruded through a spinneret, a device equipped with multiple fine holes. This creates thin streams of molten polymer, which are rapidly cooled and solidified into continuous filaments. Key process parameters, including the temperature of the polymer melt, extrusion speed, and cooling rate, are precisely controlled to tailor the yarn's final characteristics. For instance, higher extrusion speeds coupled with rapid cooling can result in finer fibres, enhancing tensile strength.

The elasticity and durability of the spandex are largely influenced by the molecular weight and viscosity of the polymer. Melt spinning stands out from traditional yarn spinning methods with its improved energy efficiency, lower environmental impact, and superior control over fibre properties. Nonetheless, producing spandex yarns through melt spinning poses unique challenges, particularly in maintaining a balance between elasticity and strength. Overcoming these challenges necessitates meticulous selection of polymer materials and process condition optimisation, ensuring the yarn fulfils the desired criteria for comfort, stretch, and resilience in its various applications.

Melt Spinning: A competitive New Process

In recent years, very low cost melt-spinning equipment has been developed and is offered today in Asia for a price that is 20 per cent of that of a dry/wet plant of equivalent production capacity. This new process attracted many newcomers into the spandex production field.

In addition, recent developments brought more adequate TPU polymers and the introduction of pre-polymer into the melt stream of TPU to improve the elastic characteristics of the produced yarns. All these developments have further pushed this process forward.

Still there are drawbacks in producing melt-spun spandex. Among them are the short lifetime of spinneret, repeated cleanings of manifold; non-uniformity of the yarn that causes a zebra effect in the end product; recovery of less than 90 per cent and a high (300 per cent) modulus; a low melting point and the limited range of deniers that can be economically produced. In spite of these drawbacks, melt-spun spandex production facilities continue to expand, particularly in China where demand for spandex yarns is still growing, with imports amounting to more than 30,000 tons in 2002.

For the above reasons, a lot of attention has been given to equipment, raw materials and technology to further improve the melt- spinning process for spandex.

Overcoming the Drawbacks

The drawbacks of using melt spinning process can be overcome by taking some basic necessary steps. Selection of raw materials with the right specifications is the key and most important point.

TPU and pre-polymer, or crosslinker, (made by PTG and MDI) are available from a number of sources. Process stability and final yarn quality are affected by a variety of factors: the NCO percent of the pre-polymer used and the amount of pre-polymer added in the process; the manner in which this low-viscosity material is introduced into the high-viscosity, high-pressure melt of TPU; the mixing of these two streams in and after the extruder by various mixing techniques; and the residence time within the manifold. The spinneret is also crucial to the quality of the final yarn produced. The design of the spinneret assembly including hole diameter, hole layout within the spinning head and filtering of the melt all play a major role in the life of the spinneret and spinning efficiency.

Solving the Zebra Effect

The non-uniformity of yarn that causes the Zebra effect is a well- known problem to melt spinners of polyamides. With elastic yarns like spandex, the problem is even more difficult to resolve.

Uneven yarn is not acceptable in fine-denier spandex used, for example, in hosiery, even if the spandex is covered by nylon yarn before circular knitting since the Zebra effect will show on the final product, thus downgrading its quality.

The solution to this Zebra effect problem involves finding the right spinning conditions, such as manifold and spinning head temperature, spinneret design, quench-air temperature, relative humidity, blowing speed and uniformity of air stream, and aging of yarn packages after winding.

High-uniformity, melt-spun spandex yarns of perfect evenness for hosiery applications are being produced today after finding the spinning conditions necessary to meet this quality requirement.

Another problem is that the recovery of melt-spun spandex is in many cases below 90 per cent versus a desired recovery level of more than 95 per cent. Modulus of around 1 gram/den for 40-denier yarn at 300 per cent is often found, and this is more than double the desired level. These two elastic characteristics of the yarn stem from the type of raw materials used, NCO percentage, the amount and mixing of the pre-polymer, residence time within the manifold, and spinning conditions. High recovery and 300 per cent modulus of 0.5 gr/den for 40-denier are now being produced after all of these spinning conditions have been optimised.

Role of Raw Material Suppliers is Vital

The low melting point of melt-spun spandex depends solely on the raw materials used. This issue is best solved by the raw materials suppliers, as it is up to them to alter the mix of materials used in their production of TPU to arrive at higher yarn melting point. One leading supplier is already delivering a higher melting point raw material and a second major supplier is developing an improved raw material having a higher melting point as well.

With PTG and MDI market prices of less than $2/kg, raw material suppliers of TPU and pre-polymer mainly made by these two raw materials must decide whether they wish to support further expansion of the spandex melt spinning into deniers such as 40 where selling prices are much lower in comparison with 15 or 20 denier by selling their raw material at prices that will give spandex melt spinners the margins they need to justify making these products.

In case of one leading TPU and pre-polymer supplier, who is also supplying the PTG to dry-spinning process users, this is a strategic issue this supplier must address. In conclusion, it seems that the melt spinning of spandex will grow substantially in the near future mainly due to the low entry investment involved, shorter installation time, and ease of operation.

No doubt a faster acceptance of melt-spun spandex yarns will much depend on the overall quality of this sophisticated high-priced yarn. Once the drawbacks are taken care there is no doubt that it will have a huge acceptance in the market as the price will be much less as compare to those produce from conventional methods.

Comments