S. Ariharasudhan | R. P.Sundaram |

ABSTRACT:

Smart polymeric materials respond with a considerable change in their properties to small changes in their environment. Environmental stimuli include temperature, pH, chemicals, and light. "Smart" stimuli sensitive materials can be either synthetic or natural. Scientists have made many attempts to develop smart textiles by grafting the copolymerization of environment-responsive polymers (ERP) onto the surface of fabrics. Among the ERPs used for this purpose, poly (N-isopropyl acrylamide) (PNIPAAm) has attracted considerable attention due to its well-defined lower critical solution temperature (LCST) in an aqueous medium of temperature about 32-34°C, which is close to body temperature. This article summarises recent advances in the application of PNIPAAm and its copolymer hydrogels to temperature-sensitive hygroscopic fabrics, and temperature responsive fabrics. Another temperature sensitive hydroxypropyl methyl cellulose (HPMC) polymer is also briefly introduced, with regard to its application in thermally-sensitive water vapour transmission rate (WVTR) for breathable fabric.

Key words: poly (N-isopropyl acrylamide), temperature sensitive, hydrogel, hydroxypropyl methyl cellulose (HPMC), WVTR

1. Introduction:

In recent years, smart polymer/gels that experience reversible phase transitions to external stimuli have attracted special attention. These polymers/gels undergo reversible volume change in response to a small variation in solution conditions (external stimuli), such as temperature [1-6], pH [1, 7, 8], and solvent composition [9, 10]. Many temperature sensitive polymers such as poly (N-substituted acrylamide), poly (N-vinyl alkylamide), poly (vinyl methyl ether), and poly (ethylene glycol-co-propylene glycol) have been reported so far and they have been utilized in the gel form for diverse technological applications such as in controlled drug delivery, chemical separation and sensors.

Poly (N-isopropyl acrylamide) (PNIPAAm) is an intensively investigated temperature-sensitive polymer which has a simultaneously hydrophilic and hydrophobic structure and demonstrates a low critical solution temperature (LCST) at about 32 oC .In an aqueous solution, the macromolecular chains of PNIPAAm experience reversible solubility and exhibit a significant hydration-dehydration change in response to temperature stimulus. Due to its sharp temperature-induced transition and well-defined LCST, which is close to body temperature, the PNIPAAm (and in particular the PNIPAAm hydrogel) has been widely applied to temperature-sensitive drug delivery systems, separation membranes, and tissue engineering scaffolds. Recently, scientists have made many attempts to develop stimuli-sensitive textiles, or so-called smart textiles, by grafting the copolymerization of environment-responsive polymers (ERP) onto the surface of fabrics. Among the ERPs used for this purpose, PNIPAAm has attracted considerable attention, and research into it may lead to novel temperature-sensitive smart fabrics. In view of the great potential applications of smart fabrics in many areas, we will review the recent achievements in smart fabrics.

31. S.K. Vakkalanka, C.S. Brazel, N.A. Peppas, Temperature and pH sensitive polymers for modulated delivery of streptokinase, J.Biomater. Sci. Polym. Ed. 8 (1996) 119-129.

32. H. Ichikawa, Y. Fukumori, and A novel positively thermo sensitive controlled-release microcapsule with membrane of nano-sized poly (N-isopropylacrylamide) gel dispersed in ethylcellulose matrix, J. Control. Release 63 (1999) 107-119.

33. M.G. Kodzwa, M.E. Staben, D.G. Rethwisch, Photoresponsive control of ion-exchange in leucohydroxide containing hydrogel membranes, J. Membr. Sci. 158 (1999) 85-92.

34. M. Zrõanyi, D. Szaboa, H.-G. Kilian, Kinetics of the shape change of magnetic field sensitive polymer gels, Polym. Gels Networks 6 (1998) 441-454.

35. I. Lavon, J. Kost, Mass transport enhancement by ultrasound in no degradable polymeric controlled release systems, J. Control. Release 54 (1998) 1-7.

36. C.S. Hsu, L.H. Block, Anionic gels as vehicles for electrically modulated drug delivery. I. Solvent and drug transport phenomena, Pharm. Res. 13 (1996) 1865-1870.

37. R. Goldbart, J. Kost, Calcium responsive biodegradable drug delivery system, Pharm. Res. 16 (1999) 1483-1486.

38. T. Miyazaki, N. Asami, T. Urgami, A reversibly antigen-responsive hydrogel, Nature 399 (1999) 765-769.

39. T. Miyazaki, N. Asami, T. Urgami, Preparation of an antigen-sensitive hydrogel using antigen-antibody bindings, Macromolecules 32 (1999) 2082-2084.

40. Y. Suzuki, M. Tanihara, Y. Nishimura, K. Suzuki, Y. Kakimaru, Y.Shimizu, A novel wound dressing with an antibiotic delivery system stimulated by microbial infection, ASAIO J. 43 (1997) M854-M857.

41. M. Tanihara, Y. Suzuki, Y. Nishimura, K. Suzuki, Y. Kakimaru, Thrombin-sensitive peptide linkers for biological signal-responsive drug release systems, Peptides 19 (1998) 421-425.

42. Y. Suzuki, M. Tanihara, Y. Nishimura, K. Suzuki, Y. Kakimaru, Y.Shimizu, A new drug delivery system with controlled release of antibiotic only in the presence of infection, J. Biomed. Mater. Res.42 (1998) 112-116.

43. M. Tanihara, Y. Suzuki, Y. Nishimura, K. Suzuki, Y. Kakimaru, Y.Fukunishi, A novel microbial infection-responsive drug delivery system, J. Pharm. Sci. 88 (1999) 510-514.

44. I. Kaetsu, K. Uchida, H. Shindo, S. Gomi, K. Sutani, Intelligent type controlled release systems by radiation techniques, Radiat. Phys.Chem. 55 (1999) 193-201.

45. Chen, K. S., Tsai, J. C., Chou, C. W., et al.; Materials Science and Engineering: C, (2002), 20, p.203-208.

46. Liu, J. Q., Zhai, M. L., and Ha, H. F.; Radiation Physics and Chemistry, (1999), 55, p.55-59.

47. Xie, J. B. and Hsieh, Y. L.; Journal of Applied Polymer Science, 4 (2003), 89, p.999-1006.

48. Graham-Rowe, D., Going Commando, New Sdentist, March (31), 22 (2001).

49. Hayashi, S., Room-temperature-Functional Shape-Memory Polymers, Plastics Engng, 51(2), 29-31 (1995).

50. Save.N.S., Jassal.M., and Agrawal.A.K..; Journal of Industrial Textiles, January 1, 2005; 34(3): 139 - 155.

About the author:

1. S. Ariharasudhan - I am working as a Lecturer in the department of Textile Technology, Pavendar Bharathidasan College of Engineering and Technology. I did my Diploma in Textile Technology from The karur polytechnic, B.Tech in Textile Technology from Jaya Engineering College & M.Tech in Textile Technology from PSG College of Technology. After my diploma I worked as a sample coordinator in Melo International Karur, after one years of experience I came back to my B.Tech and continued my M.Tech.I participated in various technical workshops & innovative project works. I published several articles in journals,magazines.

Area of Interest: Innovative textiles, Technical textiles, Textile composite

Email: ariharasudhan@gmail.com

2. R. P. Sundaram, senior Lecturer, Department of Textile Technology, PSG College of Technology, Coimbatore- 641004.

To read more articles on Textile, Fashion, Apparel, Technology, Retail and General please visit http://articles.fibre2fashion.com

To promote your company, product and services via promotional article, follow this link: http://www.fibre2fashion.com/services/article-writing-service/content-promotion-services.asp

2. Smart polymers or Stimuli sensitive polymers:

Smart or stimuli-responsive polymers respond to small changes in their environment with dramatic changes in their physical properties [11] (Table 1). Smart polymers are either reversibly soluble-insoluble (SIS) in aqueous media or cross-linked in the form of hydrogels.

2.1. Temperature-sensitive hydrogels

Temperature-sensitive hydrogels have gained considerable attention in the pharmaceutical field due to the ability of the hydrogels to swell or deswell as a result of changing the temperature of the surrounding fluid. Numerous researchers studied various applications of these hydrogels, such as on-off drug release regulations, biosensors and intelligent cell culture dishes [12].

Thermo sensitive hydrogels can be classified as positive or negative temperature-sensitive systems. A positive temperature-sensitive hydrogel has an upper critical solution temperature (UCST). Such hydrogels contract upon cooling below the UCST. Negative temperature-sensitive hydrogels have a lower critical solution temperature (LCST). These hydrogels contract upon heating above the LCST.

Some of the earliest work with temperature-sensitive hydrogels was done by the group of Tanaka [13]. PNIPAAm is the best example of a negative temperature-sensitive hydrogel. Hitotsu et al. [14] worked with cross-linked PNIPAAm and determined that the LCST of the PNIPAAm gels was 34.3 °C. They also found that mixing small amounts of ionic copolymers in the gels could increase the LCST. Beltran et al. [15] also worked with PNIPAAm gels containing ionic comonomers. They observed results similar to those achieved by Tanaka.

Hoffman [16] proposed the application of PNIPAAm and its copolymers for temperature-modulated drug release by bulk squeezing and surface regulation. In the bulk squeezing system, the drug that is distributed evenly inside the matrix is squeezed out of the system due to the deswelling of the hydrogel as a result of increasing the temperature of the environment above the volume phase transition temperature. In the surface regulation system, the swelling ratio of the skin layer is increased as the temperature of the system is lowered below the volume phase transition temperature, and hence, the drug molecules will be able to diffuse through the skin layer.

Chen and Hoffman [17] prepared P(NIPAAm-g-AA) gels which exhibited temperature- and pH-sensitive behavior. These gels were able to respond rapidly to both temperature and pH changes. The temperature- and pH-dependent swelling behavior was more pronounced in the graft copolymers than in random copolymers containing similar amounts of pH- and temperature-sensitive components.

The group of Okano [18-20] developed an ingenious method to prepare comb-type graft hydrogels of PNIPAAm.The main chain of the cross-linked PNIPAAm contained small molecular weight grafts of PNIPAAm. Under conditions of gel collapse (above the LCST), hydrophobic regions were developed in the pores of the gel, resulting in a rapid collapse. These materials had the ability to collapse from a fully swollen conformation in less than 20 min, while comparable gels that did not contain graft chains required up to a month to fully collapse.

The ability of PNIPAAm and its copolymers to exhibit a hydrophilic nature below the LCST and a hydrophobic nature above the LCST has attracted many researchers to create surfaces for cell culture systems [21-25]. Most cells attach and grow on hydrophobic surfaces, such as polystyrene. However, cells do not attach to a hydrophilic surface, and hence, will not grow. Currently, the method to detach the grown cell is by using enzyme or mechanical means. These methods have been proven to cause damages to the cells. By applying a coating of the temperature-sensitive polymer on top of the cell culture dishes, the cells can be detached easily by their own mechanism by simply changing the temperature. By changing the temperature from above the LCST to below it, the nature of the coating changes from hydrophobic to hydrophilic, and hence, the cells will detach from the hydrophilic surface.

Inoue et al. [26] synthesized hydrogels grafted with oligomers with two different LCSTs. The oligomers of choice were carboxy-terminated oligo NIPAAm, oligo (N-vinylcaprolactam) (VCL) and a random co-oligomer of NIPAAm and AAm. The resulting hydrogels showed two volume phase transition temperatures corresponding to the LCSTs of the grafted side chains of oligo NIPAAm and oligo VCL.They explored the possibility of applying this hydrogel to store and retrieve information as a function of temperature.

Conjugates of PNIPAAm with various enzymes have also been reported [27,28]. Hoffman and associates synthesized conjugates of oligomer of PNIPAAm and trypsin. These conjugates are soluble in solution and can catalyze enzymatic reactions. They can then be separated from the solution by thermal precipitation. The recovery of the conjugates by thermal precipitation was highly efficient (more than 95%) even after 14 cycles through the LCST. The enzyme conjugates were found to be more stable than the native trypsin both in solution and precipitated states.

Jeong et al. [29] synthesized a new biodegradable triblock copolymer of poly (ethylene glycol-b-(dl-lactic acid-co glycolic acid)-b-ethylene glycol) (PEG-PLGA-PEG). This copolymer shows sol-to-gel or gel-to-sol transitions as temperature increases monotonically. This thermo reversible copolymer is very important for drug delivery applications because it can be injected as a free-flowing solution (sol) at room temperature. Upon injection into the body, the copolymer becomes a gel at body temperature.

Another promising application of temperature-sensitive gels is controlled drug delivery for highly sensitive therapeutic agents. Kim and associates [30] developed a hydrogel of PNIPAAm and PAA which was able to effectively release the protein drug, calcitonin, in response to temperature and pH changes. Similar work was done by the group of Peppas [31]. They prepared block copolymers of PNIPAAm and PMAA, which had the ability to respond to both temperature and pH. Using these materials, they were effectively able to modulate the release kinetics of streptokinase.

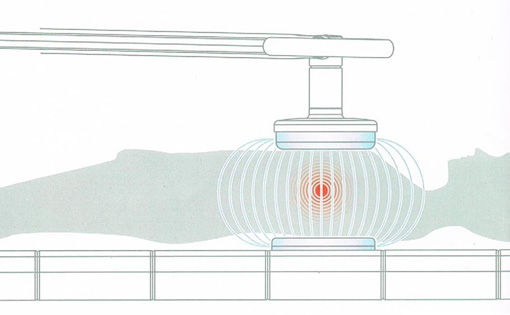

Micro- or nano-particulate devices composed of hydrogels or containing hydrogel components may have a great advantage over disk- or film-shaped macrogels hitherto developed, because they may have an improved swelling kinetics of hydrogels involving thermosensitivity of drug release property and a wide variety of biomedical applications due to their small size. A typical example of such devices was reported very recently [32]. Fig. 1 illustrates microcapsules showing the thermosensitive, controlled release in question. A key structural feature of these microcapsules is their composite coat, consisting of nanoparticles with crosslinked poly (NIPAAm) shells dispersed in a thermo-insensitive ethylcellulose matrix. As shown in Fig.1, at low temperatures, the permeability of the membranes is low because of absence of void formation by the swollen PNIPPAm shells in the microcapsule membrane, leading to a low release rate of drugs. At high temperatures, the PNIPAAm shells should collapse. Thus, numerous voids can be formed in the membranes providing high drug release rates. This microcapsule demonstrated thermally on-off switching release rate changes within a few min. As such, miniaturization of the hydrogel, as well as the device, makes it possible to achieve an exceptionally rapid, sharp thermosensitive response.

Fig. 1. Schematic diagram showing the ideal structure of microcapsules with thermally-modulated on-off pulsatile drug release.

2.2. Other stimuli-sensitive hydrogels:

Several stimuli, other than pH and temperature, can trigger drug release from a depot. These include physical stimuli, such as light [33], magnetic field [34], electric current [35] and ultrasound [36], which can be applied to the systems externally, and chemical stimuli, like ionic species [37], certain chemical substances and biological compounds [38]. In some cases, their effective applications can be found in engineering, rather than pharmaceutical, fields.

Versatile stimuli-sensitive controlled release systems can be fabricated, provided that the hydrogels are well designed to alter their configuration in response to these stimuli based on almost infinitely available mechanisms. Meanwhile, the elucidation of the release mechanisms relying on more complicated mass transport phenomena over conventional diffusion-regulating systems is a practically important issue in the substantial application of stimuli-sensitive controlled release devices. In this context, Lavon and Kost [35] examined mass transport enhancement in non-erodible polymeric controlled release systems by ultrasound for a better understanding of the ultrasound-enhancing drug release phenomenon. They suggested that the enhancing effect of ultrasound on drug release from the systems is due to the contribution of a convective term, generated by cavitation, without any destructive effect of the morphology of the polymers. Hsu and Block [36] studied electrokinetic phenomena in three types of anionic gels (agarose, agarose -carbomer 934P, and agarose-xanthan gum) under an applied electric current for electrically modulated drug delivery. It was shown that electrical current strength and gellant content could influence both syneresis and drug migration. These findings reported by the two research groups may give a practically useful insight into the application of hydrogels to transdermal delivery assisted by electroportion, iontophoresis, or sonophoresis.

Several classes of hydrogels that respond to specific molecules have been proposed to date. Calcium-responsive bioerodible drug delivery systems were devised by Goldbart and Kost [37]. The system composed of a starch-cellulose matrix containing a-amylase, the activity of which is regulated by calcium. The principle relying on calcium-responsiveness is based on the mechanism that a-amylase in its non-active form is incorporated into the matrix composed of starch, and the matrix thus responds to calcium, which causes the non-active a-amylase to become active. As the unstabilized calcium shows the calcium concentration-dependent activity, the release of drugs incorporated in the matrix accompanying the degradation of the starch matrix is regulated in a calcium concentration-dependent manner.

Very recently, two fascinating stimuli-sensitive hydrogelbased drug delivery systems were proposed in quick succession. Miyazaki et al. [38, 39] designed a novel reversibly antigen-responsive hydrogel based on a unique idea. This hydrogel was an AAm-based semi-interpenetrating polymer network (IPN), consisting of an antibody-grafted linear PAAm and the crosslinked PAAm grafted with the corresponding antigen. In the absence of a free antigen, the hydrogel can shrink due to the intra-chain antigen-antibody binding in the polymer network, while it swells in the presence of the free antigen because of dissociation of the intra-chain binding by exchange of the grafted antigen for free antigen. This swelling/shrinking process was shown to be reversible. Due to this property, the hydrogel membrane allowed the antigen-responsive change of hemoglobin permeation through the membrane in response to stepwise changes in the antigen concentration. A striking feature of the antigen-sensitive hydrogel would be the specificity of molecular recognition. Using this hydrogel, a sensing device with a broad application for immunoassay and antigen sensing is expected to be fabricated.

A series of studies on the fabrication of a novel microbial infection-responsive drug release system was accomplished by Suzuki and associates [40-43]. They prepared a PVA-based hydrogel with specially designed thrombin-sensitive peptide linkers. In this system, a remarkably increased thrombin-like activity in microbial-infected wound exudates is utilized as a biological signal for microbial infection. Antibiotics covalently attached to the PVA-based hydrogel via the thrombin sensitive peptide linkers can be released from the hydrogel only in the presence of infection, because of thrombin-sensitive cleavage of the peptide linkers. The hydrogel can be used for a wound dressing with microbial infection-responsive controlled release of antibiotics.

The ultimate goal of stimuli-sensitive controlled release is the ability to integrate the systems to respond to more than two stimuli. Such a multi-stimuli-sensitive device has been fabricated by Kaetsu et al. [44]. It was realized by the idea based on the simultaneous installation of discrete hydrogels showing different stimuli-response into the device.

3. Applications of environment-sensitive hydrogels to textiles:

3.1. Temperature-sensitive hygroscopic textiles:

Chen et al. [45] have grafted a PNIPAAm hydrogel onto nonwoven fabrics by photo-induced graft polymerization and studied the fabrics’ temperature-respon¬sive characteristics. In their work, a temperature-sensitive PNIPAAm hydro¬gel was grafted onto a plasma-activated polyethylene terephthalate (PET) film and a polypropylene (PP) nonwoven fabric surface. Factors affecting the formation of a PNIPAAm hydrogel by photo-induced graft polymerisation were investigated in terms of the type of additives. The additives used were am¬monium persulphate (APS as initiator), N, N, N′, N′-tetra-methylethylene-diamine (TEMED as promoter), and N, N′-methy-lene-bisacrylamide (MBAAm as cross-linking agent). The results indicated that the additives of APS, TEMED, and MBAAm were beneficial in promoting the grafting yield. These grafted hydro¬gels exhibited a lower critical solution temperature (LCST) of about 32 °C, indi¬cating that the temperature-sensitive behavior of the bulk PNIPAAm hydrogel was maintained. Plasma pre-treatment has also been studied. A pre-treatment with the use of argon plasma was carried out, and a subsequent photo-induced sur¬face graft polymerisation was employed to graft NIPAAm.

A schematic diagram of the photo-induced grafting polymeri¬sation is presented in Figure 2.

Figure 2. Schematic description of photo-induced grafting polymerisation of NIPAAm gel onto PET film and the PP nonwoven fabrics surface [45].

Their experimental results indicated that such a pre-treatment can improve the binding ability between the hydrogel and matrix (see Figure 3), increase graft density, and endow the grafting PP with good permeability. After freeze-drying, a hydrogel with pore structure can be obtained.

Figure 3. SEM Images of PNIPAAm-g-PP nonwoven fabrics (after freeze-drying); (a) without pretreatment (b) with Argon plasma pretreatment [45].

It can be seen from the swelling-deswell¬ing curves that the PNIPAAm displayed similar temperature sensitiveness with/without grafting on the PP nonwoven fabrics surface (see Figure 4). Thus, grafting almost does not alter the LCST of PNIPAAm. The PNIPAAm-g-PP non-woven fabrics may be used in smart fab¬rics with a function of temperature-sensi¬tive water vapour permeability.

Figure 4. Temperature effect on the swelling degree of PNIPAAm; (A) without grafting, (B) grafted on the PP Fabrics surface [45].

NIPAAm was also grafted onto the sur¬face of cotton fibres by using the 60 Co- irradiation method [46]. The DSC results indicated that the PNIPAAm-g-cotton still maintains its temperature-sensitivity. The phase transition temperature of PNI¬PAAmp-g-cotton is around 35 °C, near to the body temperature (Figure 5). This research may be applied to developing environmentally responsive fabrics.

Figure 5. DSC curves of PNIPAAm-g-cotton in wet condition [46].

Apart from the grafting methods men¬tioned above, ammonium cerium (Ⅳ) nitrate (CAN) can also be used to initiate the grafting reaction onto the cellulose fabric surface [47]. The ordered crystal¬line and orientation structure of cotton cellulose was destroyed by pre-treat¬ment by boiling in an NaOH solution and ZnCl2 solution at room temperature respectively. The pre-treated cotton cellulose was introduced into 10 ml of 20mM CAN for 15 min, wiped with tis¬sues for the removal of extra CAN, and then immersed in 5 ml of an NIPAAM/MBAAm solution for 30 min. The co¬polymerisation was performed under N2 protection for 48h,; the grafting yield can reach up to 400% by using this grafting technology. Figure 6 shows the SEM images of a cellulose-supported PNIPAAm hydrogel. The smooth thick hydrogel layers were coated on the sur¬face of the cellulose, making the fibres nearly invisible. The onset temperature of the phase-transition is between 28 °C and 40 °C, and the swelling degree of the hydrogel deceased with the increase in temperature. Shrinkage of the cel¬lulose-supported hydrogel is observed near the phase transition temperature. The cellulose-supported thermo-sensi¬tive hydro-gel is potentially useful in wound-dressing materials and nutrient-controlled release cosmetics.

Figure 6. SEM images of cellulose-supported PNIPAAm hydrogels [47]; a) Surface Layer b) Cross Section.

3.2. Temperature-responsive textiles

Temperature-sensitive polyurethane (TS-PU) is one novel type of smart polymer. The water vapor permeability (WVP) of its membrane could undergo a significant increase as temperature increases within a predetermined temperature range. Given that property, this material can be employed in the textile industry, medicine, environmental fields and so on. For example, combining ordinary fabrics with TS-PU membranes can lead to the development of a type of smart textiles. Such smart textiles would not only be waterproof at any temperature, but also provide variable breathability in response to the climate temperature [48, 49].

Save et al [50] have made smart breathable cotton fabrics using a temperature-sensitive copolymer - poly (N-tert-butylacrylamide-ran-acrylamide: 27: 73). The cotton fabric was coated using an aqueous solution (20 wt%) of the copolymer containing 1,2,3,4-butanetetracarboxylic acid as a cross-linker (50 mol%) and sodium hypophosphite (0.5 wt%) as a catalyst, followed by drying (120°C, 5 min) and curing (200°C, 5 min). The coatings after integration to the cotton substrate retained temperature-sensitive swelling behavior and showed a transition in the temperature range of 15-40°C. The coated fabrics showed a temperature-responsive water vapor transmission rate (WVTR).

Hydroxypropyl methyl cellulose (HPMC) is an intensively investigated temperature-sensitive polymer which has a simultaneously hydrophilic and hydrophobic structure and demonstrates a low critical solu¬tion temperature (LCST) at about 55.65 °C see figure 7.In an aqueous solution, the mac¬romolecular chains of HPMC experi¬ence reversible solubility and exhibit a significant hydration-dehydration change in response to temperature stimulus. These polymers have both hydrophilic and hydrophobic groups in their structure. Below LCST, the hydrophilic interactions dominate and polymer becomes soluble in water, while above this temperature hydrophobic interactions dominate and polymer becomes insoluble in water. The gel change shape by swelling in water below transition temperature and deswells above transition temperature.

The temperature responsive smart breathable behavior of the HPMC coated fabric was studied in our research. The cotton fabric was coated using an aqueous solution (10 wt %) of the polymer containing citric acid as a cross-linker (5 wt %) and sodium carbonate (0.5 wt %) as a catalyst, followed by drying and curing. The coatings after integration to the cotton substrate retained temperature-sensitive swelling behavior and showed a transition in the temperature range of 30-40°C.The coated fabric is exposed to external temperature, it will display swelling/shrinkage or hydration/dehydration properties, and cause changes in the water vapour transmission rates (WVTR), permeance and permeability of the fabrics.

4. Conclusion

The creation of smart fabrics not only represents an academic advance in the textile industry, but will also bring convenience to our lives. Smart polymers show capabilities of responding to external stimuli and have significant potential applications in a variety of fields. The environmentally responsive fabrics based on smart polymer modification can be tailored to respond to a variety of stimuli such as temperature, pH and so on. Owing to the above-mentioned attributes, smart textiles may keep us warm in a cold environment or cool in a hot environment, guard against bacterial attack, and provide us with considerable convenience, support, and even pleasure in our daily activities.

5. REFERENCES:

1. Yong Q, Park K. Adv Drug Delivery Rev 2001; 53:321.

2. Ozturk V, Okay O. Polymer 2002; 43:5017.

3. Yildiz B, Isik B, Kis M. Eur Polym J 2002; 38:1343.

4. Hoffman AS, Afrassiabi A, Dong LC. J Controlled Release 1986; 4:213.

5. Panda A, Manohar SB, Sabharwal S, Bhardwaj YK, Majali AB.

Radiat Phys Chem 2000; 58:101.

6. Kaneko Y, Yoshida R, Sakai K, Sakurai Y, Okano T. J Membr Sci

1995; 101:13.

7. Sassi AP, Shaw AJ, Han SM, Blanch HW, Prausnitz JM. Polymer

1996; 37:2151.

8. Bokias G, Staikos G, Iliopoulos I. Polymer 2000; 41:7399.

9. Tanaka T. Gel Sci Am 1981; 244:124.

10. Ohmine I, Tanaka T. J Chem Phys 1982; 77:5725.

11. Ipsita Roy and Munishwar Nath Gupta, Chemistry & Biology, Vol. 10,1161 -1171, December, 2003,

12. Kikuchi, T. Okano, Temperature-responsive polymers as on-off switches for intelligent biointerfaces, in: T. Okano (Ed.), Biorelated Polymers and Gels, Academic Press, Boston, MA, 1998, pp. 1-28.

13. T. Tanaka, Collapse of gels and the critical endpoint, Phys. Rev.Lett. 40 (1978) 820-823.

14. S. Hirotsu, Y. Hirokawa, T. Tanaka, Volume-phase transitions of ionized N-isopropyl acrylamide, J. Chem. Phys. 87 (1987) 1392-1395.

15. S. Beltran, J.P. Baker, H.H. Hooper, H.W. Blanch, J.M. Prausnitz, Swelling equilibria for weakly ionizable, temperature sensitive hydrogels, Macromolecules 24 (1991) 549-551.

16. A.S. Hoffman, Applications of thermally reversible polymers and hydrogels in therapeutics and diagnostics, J. Control. Release 6 (1987) 297-305.

17. G.H. Chen, A.S. Hoffman, Graft copolymers that exhibit temperature induced phase transitions over a wide range of pH, Nature 373 (1995) 49-52.

18. Y. Kaneko, S. Nakamura, K. Sakai, A. Kikuchi, T. Aoyagi, Y.Sakurai, T. Okano, Deswelling mechanism for comb-type grafted poly(N-isopropylacrylamide) hydrogels with rapid temperature responses, Polym. Gels Network 6 (1998) 333-345.

19. R. Yoshida, K. Uchida, Y. Kaneko, K. Sakai, A. Kikcuhi, Y.Sakurai, T. Okano, Comb-type grafted hydrogels with rapid de-swelling response to temperature changes, Nature 374 (1995) 240-242.

20. Y. Kaneko, K. Saki, A. Kikuchi, Y. Sakurai, T. Okano, Fast swelling/deswelling kinetics of comb-type grafted poly(N-isopropylacrylamide) hydrogels, Macromol. Symp. 109 (1996) 41-53.

21. H.A. von Recum, S.W. Kim, A. Kikuchi, M. Okuhara, Y. Sakurai, T.Okano, Novel thermally reversible hydrogel as detachable cell culture substrate, J. Biomed. Mater. Res. 40 (1998) 631-639.

22. H. Sakai, Y. Doi, T. Okano, N. Yamada, Y. Sakurai, Thermo-responsive polymer surfaces for cell culture: analysis of the surfaces and control of the cell attachment/detachment, in: N. Ogata, S.W. Kim, J.Feijen, T. Okano (Eds.), Advanced Biomaterials in Biomedical Engineering and Drug Delivery Systems, Springer, Tokyo, 1996,pp. 229-230.

23. T. Okano, N. Yamada, H. Sakai, Y. Sakurai, A novel recovery system for cultured cells using plasma treated polystyrene dishes grafted with poly (N-isopropylacrylamide), J. Biomed. Mater. Res.27 (1993) 1243-1251.

24. T. Okano, N. Yamada, M. Okuhara, H. Sakai, Y. Sakurai, Mechanism or cell detachment from temperature-modulated, hydrophilic± hydrophobic polymer surfaces, Biomaterials 16 (1995) 297-303.

25. A. Kikuchi, M. Okuhara, F. Karikusa, H. Sakai, Y. Sakurai, T.Okano, Two-dimensional manipulation of confluent cultured cells, Transaction of 5th World Biomaterials Congress, Transactions, Toronto, Canada, Vol. I, 1996, p. 907.

26. T. Inoue, G. Chen, K. Nakamae, A.S. Hoffman, Temperature sensitivity of a hydrogel network containing different LCST oligomers grafted to the hydrogel backbone, Polym. Gels Network 5 (1997) 561-575.

27. Z. Ding, G. Chen, A.S. Hoffman, Unusual properties of thermally sensitive oligomers-enzyme conjugates of poly (N-isopropylacrylamide) -trypsin, J. Biomed. Mater. Res. 39 (1998) 498-505.

28. M. Matsukata, T. Aoki, K. Sanui, N. Ogata, A. Kikuchi, Y. Sakurai, T. Okano, Effect of molecular architecture of poly (N-isopropylacrylamide)-trypsin conjugates on their solution and enzymatic properties, Bioconjug. Chem. 7 (1996) 96-101.

29. B. Jeong, Y.H. Bae, S.W. Kim, Thermoreversible gelation of PEG-PLGA-PEG triblock copolymers aqueous solutions, Macromolecules 32 (1999) 7064-7069.

30. A. Serres, M. Baudys, S.W. Kim, Temperature and pH-sensitive polymers for human calcitonin delivery, Pharm. Res. 13 (1996) 196-201.