The need for interior textiles is increasing rapidly day by day, so that it provides a good scope for textile manufactures, traders and retailers, say Dr. M. Krishnakumar and D. Sureshkumar.

Interior textiles, also known as home furnishing textiles, includes specialised textiles used in homes, offices, hospitals, hotels, schools, aircraft and automobile interiors. Widely used interior fabrics include satin, brocade, corduroy, damask, matelasse, sateen, velour (heavy), velvet (heavy), calico, canvas, terry and taffetta.

How do interior textiles differ from other textiles?

Certain features differentiate interior textiles from other textile. These include:

The weight of the fabric for interiors is heavy. It is thicker since low count yarn and higher constructions of ends per inch (EPI) and picks per inch (PPI) are used.

The fabric is made wider than other fabrics to cover the wider area of interiors of buildings.

These fabrics are normally made using dyed yarns instead of dyeing fabric later, because most of the interior textile designs are made in woven designs. The designs are mostly dobby and jacquard designs.

The finishing applied is mostly functional finishes like flame resistance, soil resistance and stain resistance.

The expected durability of the interior textile can be for 10 years or more.

Interior textiles are subjected to rigid testing requirements to see how it stands up with regards to fire repellence, smoke emission and abrasion resistance.

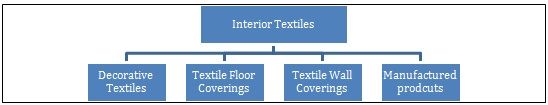

The interior textile industry is classified into

1. Decorative textile

2. Textile floor coverings

3. Wall coverings

4. Manufactured products.

Fig. 1 Interior textile classification

1. Decorative Textiles

These are mainly used to decorate the interior of the home rather than for any functional purpose.

Decorative textiles include

(i) Upholstery (ii) Draperies (iii) Wall hangings (iv) Curtains

i) Upholstery

These are the fabrics used over furniture frames and cushions. These fabrics are subjected to greater in-use stress including being used as seating for several hours.

Properties of upholstery fabrics:

Upholstery fabrics should have the following properties:

(1) Very good resistance to wear or abrasion

(2) Very high tensile strength

(3) Pleasing handling of the fabric

(4) Excellent colour fastness

(5) High resistance to seam slipping and yarn distortion

(6) It must not pill or shed

(7) It should be given stain- and soil-repellent finish

(8) It should have good flame-resistance

(9) Striped and plaid designs must be true in grain with no bow or skew

Quality standard requirements

The quality standard requirement for upholstery fabrics are as follows:

(1) Abrasion resistance - Light duty (less usage-several times/month - 3000)

(2) Dimensional stability - 3 - 5 per cent

(3) Seam breaking strength - warp (50 lbs), weft (50 lbs)

(4) Seam integrity - 0 to 0.0125" opening (or) yarn slippage

(5) Tear strength - 4-6 lbs (minimum)

(6) Tensile strength - 50 lbs (minimum)

(7) Colour fastness - (i) Cleaning (3-4) (ii) Crocking (3-4) (iii) Light (4) (iv) Gas fume (4)

ii) Curtains and draperies

Curtains and draperies, also called window fabrics, cover widows in the home or hotels or offices. They make up the major applications of textiles in the interiors. Curtains are sheer and reflecting light weight fabrics, hung without linings. Draperies are heavy, often opaque and usually have a lining. Casements are medium weight window coverings with a lower degree of transparency than curtains.

Uses of window fabrics

The uses of window fabrics are

-

To provide privacy to residents

-

To eliminate or reduce glare from sunlight

-

To hide an undesirable outside view

-

To create aesthetic effect

-

To give insulation from heat, cold and light

Properties

Besides the requirements of common textiles properties, these fabrics require good light fastness and good draping or handling.

2. Textile floor coverings

Textile floor coverings are used inside buildings. Normally, they are made by weaving, tufting, needle-punching, bonding, flocking and knitting. Also called soft floor coverings as opposed to hard or smooth floor coverings like vinyl, linoleum, cork and rubber tiles or sheets, textile floor coverings are used at home and in hotels, hospitals, airports and automobiles. The fibre content and construction play an important role in the properties and characteristics of textile floor coverings and its selection for use.

Textile floor coverings include

i) Carpets (ii) Rugs (iii) Underlays

(i) Carpets

Carpets are heavy fabrics used for soft floor coverings. A carpet usually covers the entire floor and is fastened to it. Rugs are the same as carpets, but have a specific size. They are not fastened to the floor. Carpets are also available as Modular Carpet or Carpet Tile. Each tile is normally 1' x 1' in size. The fibres used in manufacturing carpets include wool, nylon, polypropylene and acrylic.

Manufacturing of carpets:

Carpets can be manufactured by the following methods or techniques:

i) Tufting ii) Weaving iii) Nonwoven - needle punched and fusion bonding

Carpet quality specifications:

The quality specifications of carpets are as follows:

It should have (i) high abrasion resistance (ii) good resiliency (iii) good colour fastness (iv) low piling (v) high dimensional stability (vi) good tuft binding strength (vii) high soiling resistance (viii) good ease of cleaning (ix) good flame retardant properties

Special characteristics:

The special characteristics of a carpet are:

-

Sound absorption: to avoid sound echoing in a hall or room

-

Thermal insulation: to prevent loss of heat from a room

-

Static control: to prevent the production of static electricity

Types of carpet piles:

Tufted carpets will have pile or loops in their face side. The piles are of two types:

1. Loop pile 2. Cut pile

Fig. 2 Types of carpet pile

In the tufting machine, the substrate or backing cloth is passed over a supporting perforated plate. The creel will supply pile yarn to the needles, mounted in line in reciprocating bar measures to the width of the carpet. This penetrates through the backing cloth and perforated plate. The loops formed under the backing cloth are held by loopers while the needles are going up. The loops formed may be left as they are if a loop pile is required. For a cut pile, the loop is cut with a knife.

Carpet construction terms:

The following parameters are taken into consideration while manufacturing or purchasing a carpet:

i) Pile height ii) Pile thickness iii) Pile weight iv) Total weight v) Gauge vi) Needles/inch vii) Stitches per inch viii) Rows/inch

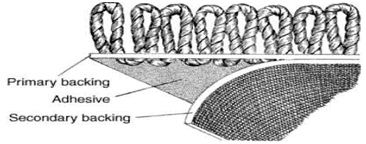

Carpet backing:

After tufting, the reverse side of the carpet is finished or bounded with a carpet backing or foam underlay. The backing may be done by:

(i) Plain backing (ii) Mesh fabric backing (iii) Underlay (iv) Foam brushed

Fig. 3 Backing of carpet

ii) Rugs

A rug is a floor covering consisting of a piece of heavy fabric that does not cover the floor's entire surface. It will cover only a specific area intended for decorative purpose or for seating.

3. Wall and ceiling coverings

Wall and ceiling coverings are fabrics placed on walls and ceilings. These may be both decorative and functional. These fabrics are normally backed with paper or spun bonded nonwoven. The fabrics used to produce wall and ceiling coverings are macram and tapestry. The major physical properties of these coverings are good flame-, soil- and stain-resistant abilities.

4. Manufactured products

Manufactured products are made by cutting and sewing home textile. They include areas of bath, kitchen and table tops, and bedding products. They are also referred to as linen because they are normally made of linen.

i) Bath Products:

Bath products include towels made of terry and velour (cut loops).

ii) Bath Rugs and Mats:

Bath rugs are small, decorative soft flooring, light in weight. Bath mats are similar but smaller than rugs and meant to be kept in front of a tub, shower etc. Both are for functional purposes.

iii) Shower Curtains:

Shower curtains are made of plastic sheets and nonwovens and are used to prevent water splashing outside the shower area.

iv) Bedding Products:

Bedding products are also called Domestics. The vertical includes

a) Sheets and pillow cases

b) Blankets - tufted, knitted, needle-punched nonwovens

c) Bedspreads - outr bed covers

d) Quilts - also bed covers but in two layers and using fabric insulative substance

e) Pillows - bed or decorative made in different shapes and sizes

v) Table top products:

Table tops are items which adorn dining table (table cloth, napkins, placements, etc.)

It is made of wovenfabrics like dobby, jacquard design, stain, sateen, etc. and lace fabrics like Nottingham lace or Raschel lace.

vi) Kitchen products:

Textile products used in the kitchen include aprons, gloves, masks and head coverings.

The manufacturing of interior textiles in India is becoming more organised because of availability of various modern technologies and techniques. Changing consumer needs are driving the scope for research and development in interior textiles. The growth potential of the interior textile market in India is positive. Earlier, it was export-oriented. Now, it is becoming more domestic-oriented because of the increasing demand at home as Indian consumers become more conscious about home interior designing and decoration.

About the

authors:

Dr. M. Krishnakumar is working as

an Associate professor in the department of Fashion Management Studies in NIFT,

Kannur. He has completed Ph.D, MBA, BSc (CDF) and Diploma in textiles.

Mr. D. Sureshkumar is working as

an Assistant Professor in the department of Fashion Technology, NIFT, Kannur.

He has completed his B.Tech and M.Tech in textile technology.

Image

courtesy:

1. Carpetcityonline.net

2. Rugandcarpets.com

References:

1. Technology of Textile

Properties: An Introduction, Marjorie A.Taylor, Forbes Publication

2. Interior Textiles: Fabrics,

Application and Historic Styles, Karla J. Nielson, Wiley

3. Carpetcityonline.net

4. Floorwisewa.blogspot.in

5. Rugandcarpets.com

6. The Free Dictionary by Farlex

7. Encyclopedia Britannica

Comments