Electronic textiles (e-textiles) are fabrics made from yarns that carry electronic components says Kunal Singha.

1. Introduction

We can say that electronic textiles (e-textiles) are fabrics that have electronics and interconnections woven into them. Components and interconnections are intrinsic to the fabric. The most convenient point is that not only having "wearable" capabilities like any other garment, but also to have local monitoring and computation, as well as wireless communication capabilities. The sensors and simple computational elements are embedded in e-textiles, as well as built into yarns, with the goal of gathering sensitive information, monitoring vital statistics, and sending them remotely (possibly over a wireless channel) for further processing.

1. Concepts of Electronic-Textiles

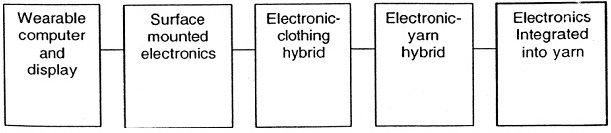

Electronic textiles (e-textiles) have evolved from the concept of wearable computers. The wearable electronics and electronic textiles lie at the two ends of a spectrum that ranges from added-on electronics to components integrated with textile yarn to true integration. A first-generation wearable computer system is wearable, it is not integrated into the clothing of the user but in the second generation of wearable computing, the system is surface mounted on clothing in a hybrid package.

More recently researchers had developed a third generation of wearable electronics where the electronic and the clothing functions are equally important and both the dress and the necklace meet clothing and esthetic functions and they carry lighting and sensing functions.

1.1 Integration of Electronics textiles at yarn level

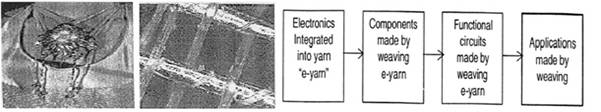

E-textiles represent integration at the yarn level. E-yarns are used to make functional circuits, and are made functional by weaving. This approach is illustrated in Fig.1. The weft yarn of this fabric is silk wound with copper foil. This is an example of hybrid electronics at the yarn level. The wearable electronics follow the microprocessor model and E-textiles are hybridized with silicon integrated circuits.

Figure 1. Integration of Electronics at yarn level

1.2. Connectivity of Electronics textiles

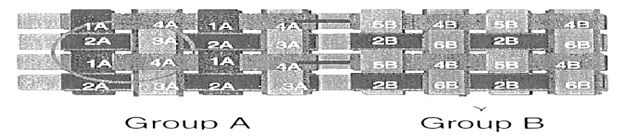

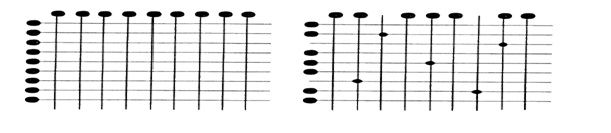

As the connectivity of a fabric is increased, it becomes stiff and its drapability is reduced. Cell of an on-yarn circuit used for sequential sampling of sensors mounted on the yarn (Fig. 2).

Figure 2. Each D flip flop contains 8, plus 1 pass transistor = 17 per cell.

2. Materials and fabrication

Silicon based thin film transistors fabricated at temperatures as low as 150oC, can be made on foils of glass, steel, and of certain organic polymers.

2.1. Intelligent textiles or Electronic textiles

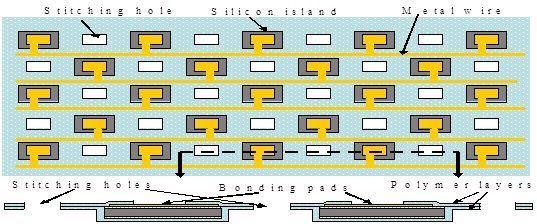

Intelligent textiles are in simple terms consists concerning silicon-based flexible skins or newborn technology. Its convenience with modern MEMS (Micro Machined Transducers) and IC technologies is assisted through a flexible pores and skin consist on silicon islands so much militia sensors, electronics, or bonding pads. The metal interconnects wires among silicon islands upon the surface about the fabric (Fig. 3). The internal the polymer layers up to expectation sandwich silicon islands and metallic wires. The interconnectivity is due to the stitching holes etched via polymer layers.

Figure 3. Top and cross section views of the proposed flexible skin to be woven into textiles

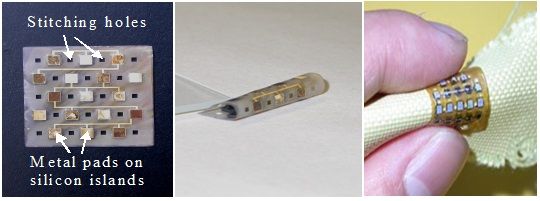

Figure 4. (a) A silicon bendy skin with stitching holes; (b) a folded silicon bendy skin; (c) A silicon flexible skin stitched onto the surface over a quantity over a fabric.

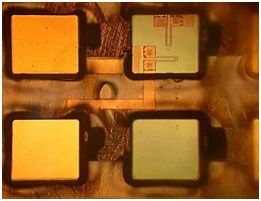

The e-textiles can lie immediately attached as a machine in accordance with the immediately embroidered in textiles. Generally, to lesson the mechanical houses concerning the phlegmatic clever textiles, diffused silicon stress gauges were built-in regarding silicon islands as much shown into the Fig. 5. These stress gauges allow in-situ excuse concerning the strains skilled by way of the silicon islands all through stretching, twisting, then bending.

Figure 5. Strian gaused e-textile silicon insland

3. Applications of e-textiles

There are lots of scopes and application is going on around the globe in the recent area due to its state-of-art and portable quality. The different applications of e-textiles are described as follows:

3.1. Wireless smart suit

The Wi-Fi clever suit is old because of hydrotherapy classes among swimming-pools because that affords an amenities move and fervor on the patient body or additionally helps according to increase the heart rates of the patient. At the decrease temperature ambiance condition intestinal the swimming-pool the heart beats and physique metabolic dimensions is animal maintain with the aid of wireless smart swimsuit or additionally such is entirely lightweight, laptop washable, comfortable, easy-to-use vest together with embedded sensors.

3.2. Design of wireless smart suit

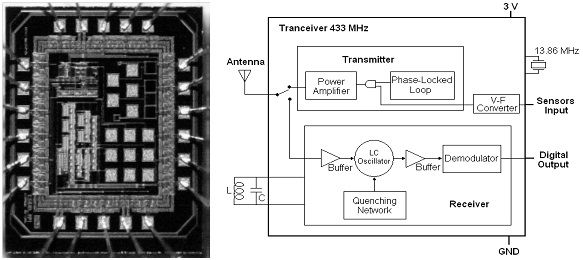

The monitoring electrodes, the sensors and the electronics are sewed in the textile material. A single-channel measures heart rate is then implemented on a 2-axis accelerometer senses patient posture and activity level. A community of CMOS temperature sensors disbursed in the go well with is old because of control the physique and cloud temperature then a RF transceiver running at 433 MHz, together with ASK modulation, was once created of 0.7 ?m CMOS (Complementary Metal-Oxide-Semiconductor) manner (with 2 metals and 1 polysilicon layer) A three V battery is required because of the transceiver. The 433 MHz provider frequency is generated with the aid of a phase-looked-loop (PLL) in transmitter section. The notice sign about the PLL is generated by a pellucid oscillator assignment at 13.86 MHz. The sensors enter are related in accordance with a voltage-frequency converter (V-F converter) between kilter according to achieve a digital PWM (fig. 6).

Figure 6. (a) RF CMOS transceiver at 433 MHz� (b) 433 MHz RF CMOS transceiver block-diagram

5. Limitations of E-textiles

Limited reliability yet trouble concerning stuff production yet processing and tankage capability-limited control furnish particular thoroughness of functions namely no longer as much bendy as much fabric clothing.

6. Conclusions

Smart interiors Switching then stress sensing integrated invisibly within interior. Textiles within the domestic and office to monitoring lighting, security, anger yet mean digital appliances. Light switches/dimmers between seating upholstery then carpets. Audio-visual far off controls within gentle furnishings, inner environmental prerequisites perform remain modified using wearing switches and through as regards dike coverings then merchandise by way of Eleksen Soft control telephone. 'Electronic Textile' future consumer look for innovative intelligent products geometric and mechanical properties of textiles (large flexible area) differ strongly from conventional electronics and can create new computer designs and architectures research which has to be carried out testing under wearing conditions washing/cleaning treatments investigation of reliability. 'Electronic textile' is a result of the convergence of microelectronics with textiles surrounding us in our daily life used in clothing, home textiles, military, navy, medical application without compromising those facts as limited reliability, high cost Specific range of applications and not as flexible as textile clothing.

About the author:

Kunal Singha has completed his M.Tech from IIT, Delhi and is currently pursuing PhD from IIT Kharagpur. He is an assistant professor at National Institute of Fashion Technology (NIFT), Patna. He has a four years of experience as assistant professor at PIET under Kurukshetra Univ. KUK, India. He has published more than three dozen of articles in different national and international journals.

7. References

1.J. C. Ribeiro, S. M. Oliveira, P.M. Mendes, J. H. Correia; Wireless interface for sensors in smart textiles; University of Minho, Dept. of Industrial Electronics Campus de Azurem, 4800-058 Guimaraes, Portugal.

2. Dina Meoli and Traci May-plumle; Interactive electronic textile development; Journal of Textile and Apparel, Technology and Management; Volume 2(2), Spring 2002.

3. W. B. Jordan, J.C. Strum; Electrotextiles: Concepts and challenges; S. Wagner, E. Bonderover,; International Journal of High Speed Electronics and Systems, 12(2), 2002, 391-399.

4. R. B. Katragadda, Y. Xu; A Novel Intelligent Textile Technology Based on Silicon Flexible Skins, Proceeding of the International symposium on wearable computer 2005 (ISWC05), Osaka, Japan, Oct. 18-21, 2005.

5. Z. Nakad, M. Jones, T. Martin, R. Shenoy; Using electronic textiles to implement an acoustic beamforming array, A case study Pervasive and Mobile Computing, 3(5), 2007, 581-606

6. A pilot evaluation of an electronic textiles for lower limb monitoring and interactive biofeedback, Procedia Engineering, 13, 2011, 513-518.

7. D. Haeringer, J. Goschnick; Characterization of smelling contaminations on textiles using a gradient microarray as an electric nose, Sensors and Actuators B: Chemical, Volume 132(2), 2008, 644-649.

8. M. Panhuis, J. Wu, S. A. Ashraf, G.G. Wallace; Conducting textiles from single-walled carbon nanotubes, Synthetic Metals, 157(8-9), 2007, 358-362.

9. Rakesh, B. Katragadda, Y. Xu; A novel intelligent textiles technology based on silicon flexible skins, Sensors and Actuators A: Physical, 143(1), 2008, 169-174.

10. Z. Nakad, M. Jones, T. Martin, W. Fawaz; Networking in E- textiles Computer

Communications, 33(6), 2010, 655-666.

11. J. Coosemans, B. Hermans, R. Puers; Integrating wireless ECG monitoring in textiles, Sensors and Actuators A: Physical, 130-131, 2006, 48-53.

12. N.M.H. ElDefrawy, H.F. Shaalan; Integrated membrane solutions for green textiles industries, Desalination, 204, 1-3, 2007, 241-254.

13. C.H. Xue, J. Chen, W. Yin, S.

Jia, J. Ma; Superhydrophobic conductive textiles with antibacterial property by

coating fibers with silver nanoparticles, Applied Surface Science, 258(7),

2012, 2468-2472.

14. S. Khumpuang, K. Miyake, T.

Itoh; Characterization of a SWNT-reinforced conductive polymer and patterning

technique for applications of electronic textiles, Sensors and Actuators A:

Physical, 169(2), 2011, 378-382.

15. S. K. Bahadir, V. Koncar, F.

Kalaoglu; Wearable obstacle detection system fully integrated to textiles

structures for visually impaired people, Sensors and Actuators A: Physical,

179, 2012, 297-311.

16. S. Wan Chung, H. Tae Kim;

Interfacial reliability between hot-melt polyamides resin and textiles for

wearable electronics application, Microelectronics Reliability, 52(7), 2012,

1501-1510.

17. H.C. Chen, K.C. Lee, J.H. Lin,

M. Koch; Comparison of electromagnetic shielding effectiveness properties of

diverse conductive textiles via various measurement techniques, Journal of

Materials Processing Technology, 192(193), 2007, 549-554.

18. D. Zou, Z. Lv, X. Cai, S. Hou;

Macro/microfiber-shaped electronic devices, Nano Energy, 1(2), 2012, 273-281.

19. C. Yuan, L. Hou, D. Li, L.

Shen, F. Zhang, X. Zhang; Synthesis of flexible and porous cobalt

hydroxide/conductive cotton textiles sheet and its application in

electrochemical capacitors Electrochimica Acta, 56(19), 2011, Pages 6683-6687.

20. Bedeloglu, A. Demir, Y.

Bozkurt, N.S. Sariciftci; A flexible textiles structure based on polymeric

photovoltaics using transparent cathode, Synthetic Metals,159(19-20), 2009,

2043-2048.

21. P. Gould; Textiles gain intelligence, Materials Today, 6(10), 2003, 38-43.

Comments