Viscose has been a fibre loved by consumers on account of its excellent attributes of comfort, fluid drape and aesthetic appeal, write Ajay Sardana and Amit Dayal

Made from a renewable natural resource- wood pulp, viscose has been a preferred choice across applications like women's fashionwear, menswear in blends and in home textiles.

Made from a renewable natural resource- wood pulp, viscose has been a preferred choice across applications like women's fashionwear, menswear in blends and in home textiles.

Why dope-dyed fibres?

Wet processing, a common step used in the textiles industry, has the potential to cause a significant impact on the environment and on human health. This is because large amounts of chemicals and dyes are used in wet processing, resulting in effluents with a complex chemical composition. The cellulosic textiles industry consumes a large quantity of water in wet processing operations like desizing, scouring, mercerising, bleaching and dyeing during conversion of fibre to fabric.

The last decade has seen growing concern about environmental issues which have increased manifold because of increasing industrial pollution, waste problems and the effects of global warming. In this context, dope-dyed viscose is one of the solutions in reducing environmental pollution and wastewater discharges in the textiles industry.

Benefits of dope-dyed viscose

Dope-dyed viscose as an alternative offers innumerable advantages.

Sustainability: To verify the issue of sustainability, a qualitative life-cycle assessment between viscose dope dyed knitted fabrics and viscose piece-dyed knitted fabrics has been completed by the North India Textile Research Association (NITRA). It is clear from this independent study that:

Greenhouse gas emissions are reduced up to 20 per cent by using spun-dyed viscose, compared to the conventional dyeing of viscose.

Wastewater generation is reduced up to 10 per cent and a significant reduction is noticed in heavy metal concentrations in the effluent generated by spun-dyed viscose.

By adopting dope-dyeing, less chemicals and energy are needed as the process is short and less wastewater is generated. This enables direct savings on production costs, and ensures substantial reduction of the environmental footprint of the final products.

Quality: Dope-dyed viscose-based fabrics have better wash and

perspiration fastness (rating of 4-5 for both wash and perspiration fastness

against rating of 3 for piece-dyed fabrics) against piece-dyed viscose fabrics

though there is no significant difference in rubbing and sublimation fastness.

Quality: Dope-dyed viscose-based fabrics have better wash and

perspiration fastness (rating of 4-5 for both wash and perspiration fastness

against rating of 3 for piece-dyed fabrics) against piece-dyed viscose fabrics

though there is no significant difference in rubbing and sublimation fastness.

Cost: Apart from the above,

dope-dyed viscose fabric is about ₹15-20 per kg cheaper compared to piece-dyed viscose. Ease of

processing: As the fibre is already dyed, the process of dyeing is completely

eliminated leading to the saving of a large amount of resources such as water,

energy and chemicals. This results in less loading of effluents into the

environment.

Regulations: China is said to be

planning to introduce an environmental tax on printing and dyeing companies.

The law, to enter into force on January 1, 2018, will be key in combating

pollution. The law will target enterprises and public institutions that

discharge listed pollutants directly into the environment.

So, dope-dyed viscose can be

helpful for manufacturers in using piece dyeing processes and facing the issues

of environmental pollution, shade consistency and cost in their production

process. Dope-dyed fibre can be a significant part of the solution to all such

problems.

Applications

of dope-dyed viscose

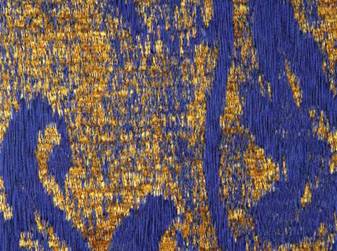

Dope-dyed viscose applications

include dress pants, workwear, uniforms, leggings, knitted tops, thermalwear,

carpets and nonwoven wipes. In all these applications, consumers will value the

benefits of dope-dyed fibres through their enhanced performance and the

conservation of scarce natural resources.

About the

authors

Ajay Sardana is chief sustainability

officer at Grasim Industries Ltd., Aditya Birla Group. He has rich experience

of more than 20 years in the global textiles industry. He heads customer and

market intelligence, liaison and sustainability of pulp and fibre business of

Grasim.

Amit Dayal is AVP of the textile research and application development centre at Grasim Industries Ltd, Aditya Birla Group, and has over 20 years' experience in areas like application development, customer value propositions, seasonal collections, technical storylines for product and market promotion.

Comments