India has the strengths in terms of raw material availability, manpower availability, large domestic market, presence of complete manufacturing value chain and government support. This has enabled growth of the industry. To sustain the growth that the Indian textiles industry has experienced, it becomes imperative for industry to incorporate certain structural changes in it. A white paper from Wazir Advisors Pvt Ltd, titled 'Achieving sustainable growth in textiles and apparel industry through manufacturing excellence', has argued that achieving manufacturing excellence through sustainable development is the way forward for the Indian industry. The white paper has been authored by Varun Vaid, Anubha Sehgal and Vanshika Jain.

The textiles and apparel industry of India has established itself as a leading exporter and consumption base. Today, the combined market size of exports and domestic consumption of the industry stands at $122 billion which includes exports worth $7 billion and domestic apparel market worth $63 billion, domestic home textiles market worth $6.5 billion and domestic technical textiles market worth $15 billion. To sustain the growth that Indian textiles industry has experienced, the industry will be required to reform, perform and transform its traditional functioning and outlook. Achieving manufacturing excellence through sustainable development is the way forward for the Indian industry. This white paper talks about the vision for industry growth and the roadmap to manufacturing excellence while creating a sustainable and innovative future for the Indian textiles industry.

India has the strengths in terms of raw material availability, manpower availability, large domestic market, presence of complete manufacturing value chain and government support. This has enabled growth of the industry. To sustain the growth that the Indian textiles industry has experienced, it becomes imperative for industry to incorporate certain structural changes in it. The major underlying issues of the textile and apparel industry of India are its unorganised structure and lack of requisite scale. This has resulted in the inability of Indian textiles and apparel industry to reach its full potential. In the cost-competitive global textiles industry, the Indian textiles sector has to take some steps to gain an edge over its competitors like China, Bangladesh, Vietnam, etc.

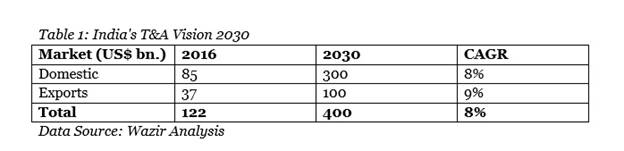

By focusing on manufacturing excellence, India could aspire for a growth of 8 per cent and reach $400 billion by 2030.

Manufacturing excellence: The only way

Achieving 'The Vision' of $400 billion by 2030 is not going to be easy and is improbable with business-as-usual approach. To attain such growth target, industry is required to take some important measures.

With fierce competition in the market, the requirement of low cost products has increased. Unfortunately, cheap labour is not the only requirement to achieve this goal. Cost advantage comes through superior product quality, innovative design, customisation, on-time delivery, technology innovations and finally admirable after sales service. All these factors culminate to customer satisfaction. The ability to deliver on these parameters is what constitutes manufacturing excellence.

The key components of manufacturing excellence are as under:

Operational excellence: The constituents of operational excellence include streamlining manufacturing operations, quality & process improvement, capacity improvement, and information systems for operations & control. Thus, an ideal production process would be where throughput time is minimal, inventory is balanced, bottleneck operation is none, changeover time is negligible, defects are zero, and critical path is well defined.

Manpower: The shortage of talent calls for recruitment of right people and retaining the talent to achieve maximum benefit. Hence, it becomes important for the businesses to not only locate and recruit employees but also bring a change in the working environment as well for their successful retention.

Market Intelligence: Since every market is different, it is important for companies to develop a strong understanding of each market and how their product will fit to improve their chances of success. Entering into market without proper understanding may lead to financial loss, wastage of time and management frustration. Moreover, exploring the markets helps in analysing global competition. Therefore, it is also important to consider an analysis of competitors.

Continual Improvement: Creating and embracing continuous improvement of people, processes and product leads to achievement of excellence. Continuous improvement is all about leading by doing and empowering employees to make continuous improvement.

Roadmap to manufacturing excellence

To remain competitive in the international market it is important to simultaneously improve quality and productivity on continual basis. Manufacturing excellence thus is the need of the hour to sustain the growth that Indian textile industry has experienced.

Productivity improvement programme: To achieve higher productivity, India has to emphasise on all areas of manufacturing including manpower, material, machine and capital. The key components of productivity improvement programme are production planning and control, improvement in system and processes and increasing focus on information technology.

I. Planning and merchandising: Apparel manufacturing in India is highly dispersed. Due to the innate nature of the industry, enterprises have to devise effective planning mechanisms that involves:

a. Estimating next six months capacity so that orders can be allocated in advance;

b. Allocating right order to the right factory;

c. Production plans for tools and materials, supplier planning, manpower;

d. Master production schedules (MPSs);

e. On-time customer approvals;

f. Effective material procurement;

g. Regular follow up on time and action (TNA) calendar;

h. Coordination among factories.

II. System and processes: The textiles and apparel Industry is labour-intensive due to which it is difficult to standardise operations. To overcome this problem operations re-engineering can be adopted which stresses on tools like high-performance layout, quick changeover module (QCO), quick quality response (QQR), etc. These kind of standard operating procedures (SOPs) bring in optimisation of process flow and streamlines it.

III. IT focus: IT is significantly missing in the industry in both small and large enterprises. IT tools like management information system (MIS) and enterprise resource planning (ERP) can be utilised for achieving efficiency and improving quality of production. It automates work flows and makes the process faster and traceable to identify delays.

Continuous research and product development: Continuous focus has to be given to research and product development in order to gain competitive advantage. Bringing new ideas into action is of importance as it can lead to finding new manufacturing methods to improve performance, producing better quality and designs and streamlining of the entire process flow.

Skill development:High performance training in the textiles and apparel industry is important as manpower involvement is more than any other industry. It includes components such as:

I. Foundation training: Once the operator is selected through aptitude test he/she undergoes induction process where he/she is given awareness about basic machines. Machine training is given to achieve variable speed pedal control, loop exercise, control of machines in high/low speeds.

II. Intermediate training module: The training is customised based on operator performance in the foundation module and handling different products.

II. Advanced module: The trainee is prepared for a reallife industry situation through soft skill training and visual training. The new recruits have to be placed in real time production lines and need effective monitoring so that they are able to handle mass production.

Apart from technical skills, it is important to provide operators with soft skills which includes motivation, health & hygiene, social security, group behaviour, personal finance, self-management, time management, team management, etc.

Keeping an update on market trends and global practices helps the companies in:

I. Identification and understanding of market dynamics;

II. Understanding consumer trends and how their products can fulfill or create a need;

III. Choosing the correct way of diversifying business;

IV. Getting insights into competitors strategies, operations, strengths and weaknesses;

V. Finding out the key success factors to play and win in that specific market.

Government support required

This roadmap to manufacturing excellence can be supported by government along with the efforts from industry to achieve manufacturing and sustainability goals. Various schemes like Technological Upgradation Fund Scheme (TUFS), Scheme for Integrated Textile Parks (SITP), Integrated Skill Development Scheme, and others have been launched for promoting investments in the textiles industry, upgrading technology and setting up integrated manufacturing setups. Apart from central government schemes, several state governments have also launched their textile policies under which several incentives are provided for investments in textile sector.

The ₹6,000crore garment package last year came as a very positive boost for the garment industry. All this support from the government has helped the industry to grow over the years and become more competitive in manufacturing and exports. This support has to be continuously enhanced and focused on the target areas by creating a catalyst scheme to develop an ecosystem for enhancing manufacturing competiveness in order to provide a strong base for the future development of the Indian industry.

With the aim of supporting Indian textiles and apparel industry achieve its deserved state, it is important that state and central government agencies provide special thrust in specific areas:

R&D Support:

The Indian textiles and apparel sector is known for its traditional products, but very limited innovation has taken place in the sector so far. Even for several homegrown technologies and process, commercial acceptability and adoption is not there in the sector. When compared to other competing countries, the efficiency and productivity levels of Indian textile sector is quite low. The government can have a R&D fund, which could be used for deploying state-of-art modern technologies.

Credible mechanisms for assessing levels of quality and productivity: There is a need to develop credible mechanisms for assessing levels of quality and productivity in segments of the supply chain as well as in individual enterprises. The government should work together with the Quality Council of India and the National Productivity Council for achieving this objective.

Attracting foreign direct investment (FDI):

Owing to various initiatives taken by the government, the FDI in the textiles sector has increased considerably. In the 2016-17 fiscal, the sector received an FDI of $619 million. However, this is not enough to get the desired technical know-how, and marketing network required to produce and sell high-end products competitively. Hence, the Indian textiles industry needs to focus on investing in latest technologies and developing world-class manufacturing infrastructure.

Attracting large-scale investment:

To be globally competitive, it is required to promote large-scale manufacturing set-ups. These set-ups will gain an edge because of economies of scale and will also be able to cater to large buyers. For attracting investments in the sector, it is required that good incentives should be given to investors. Incentives focused on technology up-gradation, capacity addition and long term development of the sector are crucial at this point of time. The incentives need to be attractive enough for Indian as well as international investors. Improved investment environment will stimulate investments, provide technical know-how and develop state-of-the-art set-ups required for the sustainable development of the sector.

Comments