Hans Wroblowski, Area Sales Director and Head of Product Management for Denim at Monforts, proposes some positive measures for keeping a step ahead in textile manufacturing with Industry 4.0.

We are currently facing the biggest challenge of our times - what is now being referred to as the 4th Industrial Revolution.

A. Monforts was founded in the year 1884 and our evolution in textile engineering and machine building has progressed from mechanical, steam and water-powered technologies to the first mass production lines, electronic drives and highly modular machines such as our stenters. The move towards the current state of the art has involved firstly data transfer and storage via internet/intranet, along with teleservice solutions, followed by full automation concepts.

Now we are truly in the digital age, surrounded by smart technologies and permanent online solutions.

With online finance and shopping, expert systems have been developed for optimizing internationally-linked businesses, along with business models for global production planning, in order to achieve the shortest possible supply and delivery times.

Challenges

How should textile manufacturers respond to this situation?

At Monforts, we have a clear mission and are committed to investing in the digitization of our technology in order to help our customers respond to the fundamental challenges facing the textile industry today. These can constitute something of a vicious circle of demands and expectations as a result of:

Fragmented process chains.

Different time and production scales.

Missing standards of communication interfaces.

Small profit margins.

The reality of low margins and low profits means that textile manufacturers are ultimately fighting for every production cent which can be saved. This can result in a reluctance to invest in new textile machinery, but manufacturers really need to explore what additional value the latest technologies can deliver. The era of digitization is demanding new structures and new ways of thinking, in order to assume digital leadership.

The key benefits the latest technologies can provide include:

A reduction in the cost of energy sources.

A reduction in machinery production costs.

The sharing of process operators.

A reduction in machine downtime.

Optimised production planning.

The objectives, which will result in a rapid return on investment are:

Higher productivity.

Higher machine availability.

Increased efficiency.

The expectation of the industry is 'just in time reaction and action' and time is the most valuable asset within our industry.

The latest tools which can ensure this include:

Remote service, with easy and secure connection to the machines.

Maintenance and servicing management.

Spare parts support and a shop system directly at the machine.

Advanced monitoring and visualization of machine conditions.

Energy and resource savings

The textile industry consumes huge amounts of energy and resources at virtually all stages of production, but especially during finishing, where large volumes of water, chemicals and thermal energy are required. A significant portion of these resources, however, can be wasted without precise feeding, monitoring and control.

The optimized handling of thermal energy in particular, is currently a hot topic in the textile industry and one which offers a great deal of potential.

The latest Monforts technologies for enabling resource savings include:

-

The Matex Eco Applicator, as an alternative to padding, for minimum liquor application, especially for wet-in-wet solutions.

-

The guiding concept of this unit is "not more than necessary and result-oriented application" for liquid and energy savings of up to 40%.

-

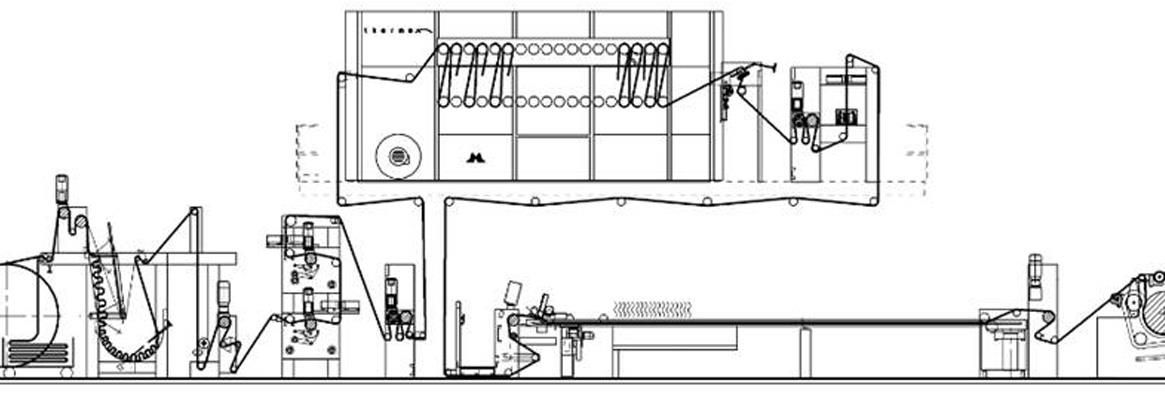

The Monfortex Eco Line shrinkage solution provides similar energy savings of up to 40% in comparison to traditional padder/cylinder dryer solutions.

-

A basic solution for the introduction of two-way super stretch into denim carried out in a single processing step.

Steps to successful digitization

Companies who choose to follow a Textile 4.0 strategy can set out their path to digitization and the application of digital concepts by following these three pragmatic steps:

Give all things a name. For all products, sets and production materials a clear ID has to be defined, for example, with a bar code and thus a unique name. Further, digitizing and connecting products and the value chain can only be made possible on the basis of clear identification.

Measure, registration, measure. Measure all process relevant information by the use of sensors. Install sensors at multiple measuring points along the production line. The availability of measuring data allows companies to improve processing time and machine ability.

Analyze Data. Connect the clearly identified products with their digital specification, their production materials as well their manufacturing related process data. Further, connect the different sources of data-machines within the production chain. Create the required communication and IT infrastructures in order to achieve connectivity and to be able to combine and analyse data with an expert system and a pre-adjustable recipe data information system.

New Horizons with Qualitex 800

The consolidation of the Monforts Qualitex 800 digital solution with the latest mechanical solution such as the Eco Applicator or Eco Line can be the basis for the efficient implementation of a range providing higher productivity and efficiency.

The Qualitex 800 offers the operator more reliability, quicker access and therefore more benefit. The easy operation by use of the latest slider and dashboard functions with individual adaption to the operating states assures faster access to comprehensive recipe data and therefore enhanced machine ability.

Through its target-oriented and integrated digital intranet/internet-based Cloud solution, the aforementioned just in time reaction and action can be achieved to ensure that supplier and customer will be always benefit from a retrievable online information service.

Summary

The significant opportunities arising from Textile 4.0 and the Internet of Things require elevated investments, with intranet and internet being the most important tools in the future of efficient corporate management.

We should not, however, underestimate the numerous challenges that this transition entails.

The main sources of the benefits in respect of productivity, efficiency and availability have yet to be defined between supplier and producer.

Of course, there are already extremely optimized textile processes in use which are executed serially in a well-defined sequence. These will be further optimized in the future and open the route to the introduction of new production approaches.

Comments