Bengaluru headquartered IIGM Pvt Ltd is the largest marketer of apparel production and ancillary related technologies in India. IIGM also supplies electrical distribution equipments and goods, air cooling solutions, skylights, HVLS fans, etc.

To supply these technologies and products, IIGM has partnered with 45 Indian and global companies-all of them leaders in their respective categories.

IIGM manages 15 offices across India, with more than 500 employees on its rolls and boasts of over 25,000 satisfied customers. All of this has been achieved in a span of four decades, which speaks volumes of the growth record and success of India's foremost technology and service provider.

In order that customers are delivered a delightful experience, IIGM offers various training programmes for its customers. It has also perfected its supply chain and logistics and created abilities to provide products through direct shipments from overseas principals, bonded warehouses, and duty paid goods.

The IIGM core teams manage each vertical with a dedicated group of sales, application and services professionals. IIGM has developed the ability to service customers ranging from small companies to the largest groups across India, Middle East and parts of Southeast Asia and makes use of the latest technologies to enhance deliverables and satisfy user experience.

IIGM represents principals who offer technologies across the whole spectrum of the apparel production chain. Apparel technologies on offer begin from product development, cutting and fusing, sewing, midprocess, washing, embroidery, printing, finishing, attachments and productivity aids, automation and end with after-market spares and consumables.

Apparel production technologies:

Within Product Development for apparel production facilities, IIGM offers technologies from Gerber Yunique Solutions, US, which include products for product lifecycle management (PLM), plotters, digitisers and CAD automation.

Within the Cutting and Fusing category, cutting solutions are available from Gerber, while semiautomatic machines are from Eastman, US. Fabric inspection machines are supplied from C-Tex, UK and fusing machines from Hashima, Japan.

Material spreading technologies are on offer from Gerber Technology, rib cutting machines from Svegea, Sweden, manually operated cutters are from Eastman, while bias slitters and strip cutting technologies are available again from Svegea.

Within the Sewing Machine category, IIGM represents global giants like Juki, Yamato and Jack. Between these companies, all kinds of stitching machines like single needle lock stitch machine, double needle lock stitch machine, blind stitch machine, post bed machine, coverstitch/flatlock/interlock machine, button stitch machine, flat seamers, over lock machine and many others are available.

In the Mid-Process category, collar preparation, sleeve placket preparation, shirt cuff preparation, pocket preparation and front placket preparation machines are available from Ngai Shing, Hong Kong.

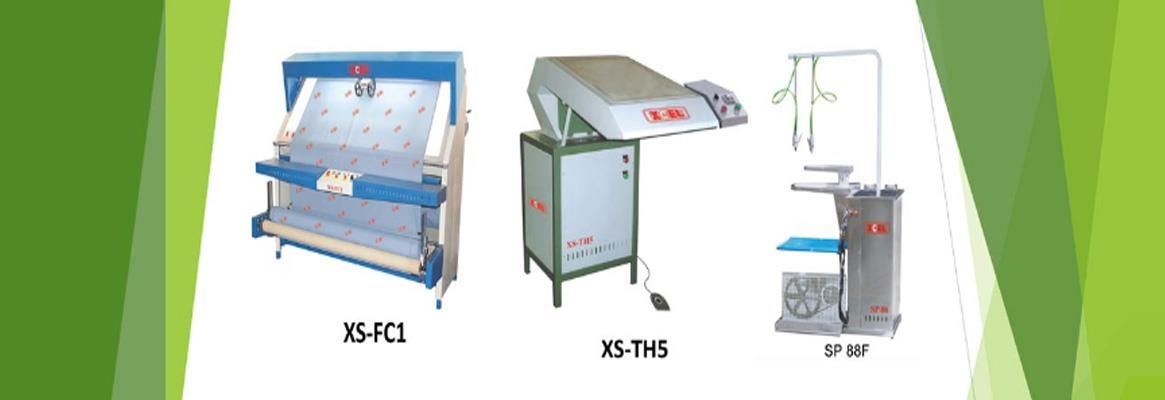

In the Washing category, speciality chemicals for textile wet processing are offered from Maple Solutions, Canada, dry process machinery from Metod Makina, Turkey, while automatic washing equipments, hydro extractors, industrial drying tumblers, industrial dry cleaning and industrial washing machines are supplied from Realist, Turkey, Ngai Shing, Hong Kong and XCEL, India.

In the Embroidery category, embroidery software is offered from Wilcom, Australia, whereas sequin embroidery, single head embroidery, multi head embroidery and special application embroidery machines are supplied from Barudan, Japan.

Infrared conveyer dryers and manual screen printing machines are supplied from Vastex, US, automatic screen printing machines from MHM, Austria, sublimation and digital printers are from Epson, Japan, laser marking and cutting machines are from GBOS Laser, US, and rhinestone machines are from CAMS, Korea.

In the Finishing category, shirt final finishing and casual trouser finishing machines are from Ngai Shing. Thread suction, stain/spot removing machines as well as steam boilers and ironing tables are offered from XCEL. Needle detection and x-ray inspection machines are supplied from Hashima, Japan, and wrinkle free garment finishing, auxiliary finishing systems, conveyer systems and pucker free & taped garment finishing machines are again supplied from Ngai Shing, Hong Kong.

Attachments and Productivity Aids like puller attachment are supplied from Racing Sewing Machine, Taiwan, thread trimmers and thread suction machines and devices from AMIDA, China, folders & binders from Wayken, Taiwan and workaids from Nga Shing, Hong Kong.

In the Spares & Consumables category, aerosols are offered from Sprayway, US, scissors and thread clippers, industrial knives and cutting machine parts from Wayken, Taiwan, machine oils are supplied by IIGM itself, power saver motors from Jack, China, hook shuttles and bobbins from IIGM again under the iShark-Mart brand and lastly LED lights supplied from Boshite, China.

Training centre:

Training has always been a part of IIGM's corporate culture. In-house training programmes, customised programmes for customers, and individual training for young entrants to the industry are offered in all the main cities of India.

IIGM training centres are known for offering full time inhouse programmes for machine maintenance, CAD, embroidery applications, productivity and quality areas, training of trainer (ToT) programmes for skill development and evaluation of technical workforce in organisations. IIGM's training programmes have received accreditation from renowned companies like Juki, Gerber, Wilcom, Barudan, Eastman, Ngai Shing, Ho Hsing, Yamato and many more.

Supply chain and logistics:

IIGM has created abilities to provide its products through direct shipments from their overseas principals, bonded warehouses, and duty paid goods through IIGM's various branches in India. These products can also be offered to overseas customers through custom bonded warehouses, while also providing door-to-door delivery services in any part of India.

All international products can be delivered seamlessly in the shortest period of time. IIGM stocks over 10,000 machines at any given point of time and also has stocks of around 200,000 spare parts of various machineries, with the commitment to supply reliable and best quality spares. This is managed through a complex SAP software for quick search and delivery.

Comments