Circular Fashion with the help of biotechnology. The ecological impact of our consumption habits has become one of the most significant concerns of contemporary times. As such, the development of goods that minimise the emission of toxic materials, waste, and pollutants has become a pressing matter for the fashion industry.

Moreover, as sustainable development has become a crucial factor in any company's success, tech startups and university research labs are looking for new ways to design innovative materials for the fashion industry, that could also have a determinant role in the future economic growth and sustainable development.

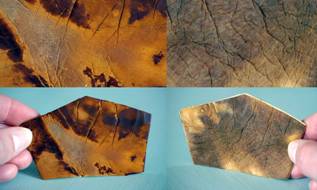

In this light, by 'deploying' biotechnological research on general fruit waste and specific types of fungi, a team of researches from Wageningen University are in the final stages of developing sustainable leather alternatives for the fashion industry.

In this light, by 'deploying' biotechnological research on general fruit waste and specific types of fungi, a team of researches from Wageningen University are in the final stages of developing sustainable leather alternatives for the fashion industry.

"When it comes to polluting our planet, the textile industry is second after the oil industry", said Kim Poldner, assistant professor and the research associate at Wageningen University & Research.

Kim coordinates the Circular Fashion Lab at WUR and is researching how fruit waste can be utilised and processed to obtain leather substitutes, usable at an automated scale in the fashion industry.

"There is no circular fashion without the capacity to recycle the goods it creates", observes Jan van Dam, an expert in biomaterials at Wageningen University & Research.

Reaching circular fashion has become critical not only for the fashion industry but for the global economy. Research shows that the sale of fashion garments has reached 100 billion articles between 2000-2015 alone. Moreover, as fashion buyers are not wearing all garments purchased, over 70 per cent of the clothes they own are never used, ending up burned or discarded as waste, rather than being recycled in a circular fashion ecosystem.

"If our initial actions towards circular fashion focused on the use of organic cotton, we are now researching fruit waste and other renewable and self-recycling resources, such as hemp and fungi," says Poldner.

"If our initial actions towards circular fashion focused on the use of organic cotton, we are now researching fruit waste and other renewable and self-recycling resources, such as hemp and fungi," says Poldner.

Experts anticipate that innovative materials will soon replace cotton and leather in fashion apparel, with enormous benefits for the industry. In a circular fashion system, garments made of fungi and hemp can be composted and pigments obtained from micro-organisms lessen the amount of global toxic waste resulting from the dyeing processes.

Plant-based apparel choices are also the answer to the tones of microplastics contaminating the oceans as a result of washing synthetic fabrics made from polyester, acrylics.

Mylium, the product obtained from mushrooms, can be grown to your needs. It is natural, sustainable, biodegradable and safe for human skin. Mylium is flame retardant, strong, resilient but lightweight and bendable. As a leather alternative, mylium feels like soft suede.

"Learning from nature and 'biomimic' its features is the next step in the circular fashion endeavour," says Kim Poldner, this time referring to collaboration in the fashion landscape rather than the development of innovative materials.

"A global problem requires a global solution. Let's learn from ants and bees working together and apply that knowledge for a circula fashion industry", she added.

This article has not been edited by Fibre2Fashion staff and is re-published with permission from thevou.com

Comments