What is Textile Waste?

Textile waste is produced in every phase of the textile manufacturing process like spinning, weaving, dyeing, finishing, garment manufacturing and even at the consumer end.

What are the Various Types of Textile Waste & What is Their Effect on the Ecosystem?

Global production of clothing and its consumption has increased in the last fifty years. With time, clothing has gained more importance as people associate every occasion, mood, season and status with clothing. It has become a way of making an impression and non-verbal communication.

Textiles is the second biggest polluting industry. The average life span of a garment is roughly three years, and so, textiles generate a huge amount of waste. Five per cent of all global landfills is being taken up by dumped textile waste.

It is not possible to avoid wastage during production or usage of textiles. Besides, a sensible analysis on the shopping behaviour and life cycle of a product among the consumers is essential. The huge quantity of textile waste dumped in landfills and incinerated can be reduced to a great level by understanding the dimensions of a product and its compatibility with nature. Textile waste is produced in every phase of the textile manufacturing process like spinning, weaving, dyeing, finishing, garment manufacturing and even at the consumer end. We can classify them as,

• Soft Waste: Generated from combing, drawing and spinning.

• Hard Waste: Generated after spinning and twisting, weaving and knitting.

Classification of Textiles Waste

The major classification of textiles waste is as follows:

a) Pre-consumer Textiles Waste: It is also called production waste and is generated from the first phase of the supply chain. The consumer never sees pre-consumer waste produced during industrial processing of textiles by the manufacturer. It includes scraps, damaged or defective material samples, fabric selvages and leftover fabric from the cutting process. On an average, about 15 per cent of fabric used in garment production is cut, discarded and wasted. The fabrics that are made from 100 per cent degradable material like cotton, linen, silk, hemp are recycled into a compost, or upcycled into a value-added product. Synthetic textiles can be upcycled into composites and building blocks to be used in construction or sound proofing applications.

b) Post-consumer Textile Waste: These are household articles or garments that the owner does not require any more and discards. The out of fashion, damaged clothes with fitting issues come under this category. Conventionally, old textiles are recycled again to fit into some household activities as a mop or wash cloth, but with the current invasion of disposable textiles, the use and throw approach is quite popular; so old textiles are thrown away. A disheartening fact is that the majority of the population has lost the art of mending or repairing of clothing and accessories. Thus a change in consumer psychology has created a harmful situation.

c) Industrial Textile Waste: It is generated from industrial applications and includes conveyor belts, filters, geo-textiles and wiping rags. On wear and tear of a particular component, the waste components are thrown away. In most cases, it is inevitable and open for downcycling, upcycling and recycling options. Many companies work on these wastes and try to incorporate the waste into an asset, thus leading to circular economy.

Causes of Textile Waste

Here are the various reasons for textile waste generation:

i) Attitude Towards Textiles: Indians have a rich tradition of using textiles and reusing them to the maximum possible extent. A sari turned into a curtain, then into rags, used as a lamp wig and then as an ash for protecting the eye (kaajal). There was always a sensible approach to textiles. Post modernisation, lifestyle has been totally influenced by various civilisations. The Western lifestyle is a significant contributor to landfill waste. Not only products are consumed at a high level, but also Western goods are often over-packaged, contributing to even more to the waste stream.

ii) Fast Fashion: In the last ten years, the toxic culture of fast fashion has replaced slow fashion. Handmade drawings are replaced by machine-made replicates that cut down time and cost. The recreation of designer clothing at the lowest possible price for mass production is possible only with the use of synthetic and harmful dyes. This fast fashion culture ultimately churns out massive amount of clothes, accelerating carbon emissions and global warming. Low-quality materials soon end up in landfills that turn a menace to handle.

iii) Frequency of Shopping: The number of items purchased has increased tremendously, mainly due to price drops. Global ‘fast fashion’ suppliers offer low-priced clothing with a short life span. It has been calculated that in the last ten years, shopping levels of women have doubled.

iv) Lack of Awareness on Sustainability: In the life cycle of any textile product, consumer disposal behaviour and their awareness about environment plays a crucial role in reducing waste. At the end-of-life stage, instead of sending it to landfill, if consumers become more open to reusing the product and forwarding the product for recycling rather than to landfill, it will certainly reduce textile wastes to an appreciable level.

v) Lack of Eco-friendly Practices: Fibre production results in wastes that are not recycled effectively. There is lack of awareness to handle fibre wastes that are of natural origin; as a result they are thrown out in huge numbers. The dark shades of textile are associated with more dye powder, and more toxic textile waste water. There is no method used for treating the waste water generated from using more dyes; yet most people wear dark coloured clothes. Toxic materials like lead, chlorine, formaldehyde are expelled into water bodies from the textile industry.

vi) No Strict Government Policies: Developed countries are working in the direction of streamlining flow of waste, proper disposal of waste, consumer awareness and strict norms. But in developing countries like India, environment legislation is stringent but poorly enforced. Trading of second-hand clothing is not properly worked out. Therefore, government’s initiatives and strict policies for trading of second-hand clothes, disposal of waste and awareness camps can be of great help to save the environment.

vii) Lack of Quality Materials: Clothing companies with mass production capability usually have confidence in their own internal knowledge about product development and design. The fashion information is often received from trend forecasting companies, fashion shows and media. Sizing and fitting of clothing is tested on fit models and graded to other sizes, and not necessarily tested on other bodies before production, thereby causing problems with fit, especially in larger size groups. If physical durability, comfort and ease of maintenance, aesthetics, etc. are addressed correctly during the design stage, then the clothes often remain useful for a longer duration and even resist fashion change over time.

viii) Less Popular Second-hand Clothing: Second-hand clothing is generally considered for low economy countries and low-income groups. It is not appreciated as a good substitute of virgin clothes that have a direct impact on the environment. Second-hand clothing markets and shops are not widely spread and are not popularly known. So these are not easily accessible to the masses at large.

ix) Consumers’ Lack of Knowledge on Textile Care and Maintenance: The commonly used style for washing garments is by using water and other chemicals like detergents, bleaches, etc. Often low-quality domestic products are freely traded without any eco labels. For proper maintenance of clothing, laboratory-based test results are important and should be mentioned clearly on labels.

x) Industrialisation: Various qualities of textiles are available in abundance to target different consumer groups leading to more pre-consumer and post-consumer textile wastes. Fashion due to its ever changing nature, is a big reason for pollution. Consumers have to be well aware of the choices they make while purchasng.

External Factors For Textile Pollution

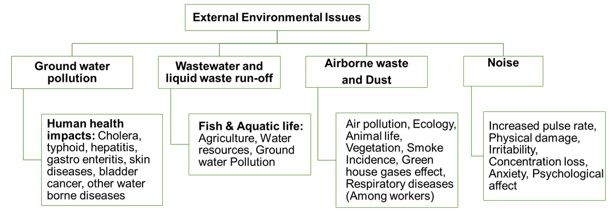

The harmful effects of the textile industry to the external components like residential areas, water resources, plants and animals are discussed in Figure 1.

1) Water Pollution: The textile industry uses millions of gallons of water daily. To produce a kilogram of fabric, typically 200 litres of water is consumed–washing the fibre, bleaching, dyeing and then cleaning the finished product. It also involves the usage of chemicals and other solvents. Liquid wastes from textiles arise mainly from wet-finishing treatments, where large volumes of water and chemicals are used.

Most dyes and chemicals used are synthetic and not readily biodegradable. The wastewater generated during these processes is highly polluted, dangerous and discharged into water bodies without appropriate treatment. This disturbs the aquatic life, along with millions of people who are dependent on the water for their day-to-day life. The solution lies in selecting clothes made in countries with stricter environmental regulations and choosing organic or natural fibres that do not require chemicals for production.

2) Air Pollution: Gaseous wastes from the textile industry containing solvent vapours like ammonia and formaldehyde are normally diffused into the atmosphere. Another form of air waste originates from boilers. Most of the textile mills use coal or gas as fuel, and large amounts of gases are released into the atmosphere making the air poisonous and laden with chemicals.

Sixty per cent of the electric power generated in India is based on the burning of fossil fuels, mainly coal, which contributes to 16 per cent of the air pollution, followed by the industry with 12 per cent contribution. Air pollutants produced by the textile industry include:

• Energy production stages: Nitrous oxides and sulphur dioxide

• Coating, curing, drying, waste water treatment: Volatile organic components

• Dyeing and bleaching stages: Aniline vapours, carrier hydrogen sulphide, chlorine and chlorine dioxide

The dust consists of fibre dust, coal dust, ash, saw dust and grain dust. This dust mixes with air and increases the suspended solids and pollutes the air. The air polluted with cotton dust during blowing, drawing, carding, combing etc, can cause health hazards like acute respiratory disorders. Thus, there is a need to use proper methods to suppress the dust and avoid making it reach the air limits.

3) Noise Pollution: Excessive noise resulting from textiles manufacturing units is threatening the life of workers and residential areas around them. It can cause permanent hearing loss. It is also reported that a large number of textile workers, especially weavers, suffer from occupational hearing loss. High noise levels are causing psychological effects and physical damage including irritability, loss of concentration, anxiety and increased pulse rate. The alternative to this is adopting friendlier practices by implementing new technologies.

4) Toxic Waste: It can be in any form–effluents, in water, air, dust, toxic organic compounds, phosphates, chlorinated solvents, non-degradable surfactants, etc, originating from various processes like fibre preparation, dyeing, printing, bleaching, cleaning, etc. The labourers in the dyeing and printing industry are frequently exposed to dyes, acids, fixatives, solvents that are harmful in nature.

Skin diseases are common in workers involved in processes like bleaching, dyeing and finishing, preparation of flax and in the use of solvents for making synthetic fibres. Certain dyestuff intermediates can produce bladder cancer. Occupational health hazards include byssinosis, chronic bronchitis, dermatitis and cancer of the bladder among dyers, and cancer of the nasal cavity among weavers and others.

Internal Factors for Textile Pollution

The textiles industry produces waste at every stage of textile manufacturing. The broad classification of environmental impact areas of textiles and clothing industries are shown in Figure 2.

Figure 2. Steps in textile production

1) Spinning Waste: The fibres generated by the spinning industry have various other materials like seeds, twigs, dead insects and dust. At each stage of spinning, there are different types of wastes like blow room waste, carding waste, dropping, sliver waste, draw frame waste, ring frame waste, and soft and hard wastes.

2) Weaving Waste: The yarns that are left on the cone after warping are called weaving waste. In the warping creel section, there will always be a little amount of yarn left on the cones. Sizing waste is another kind of waste in a weaving unit. When a new set of warp yarn is started in the weaver’s beam section, then it is necessary to eliminate some portions of the yarn to ensure properly sized yarns are wounded on the weavers beam. After sizing wastage, comes the problem of knotting wastage. Knotting is done to ensure all the warp ends of two beams are available for attaching together. Beam residual wastage is another kind of weaving wastage. When a weaver beam is finished, a small amount of warp yarn remains unused on the weavers beam and it is not possible to finish it. Auxiliary selvage wastage is also a common weaving wastage. Auxiliary selvage is a fake selvage used to hold the weft yarn during loom beat up period.

3) Knitting Waste: The art of knitting is either handmade or machine made. It is a complicated process and any fault in the technique of loop creation results in wastage. On acquiring an order, the merchandiser makes a sample, which is run for trials and to check proximity. This results in waste samples. Different kinds of knitted defects like stains, bareness, thick and thin yarns, stripes, hole, slub add to the knitted wastes from industry.

4) Dyeing Waste: The batches with shade variation, crease marks in dyed fabric, difference in shade from selvage to selvage, are usually thrown as waste in the dyeing industry.

5) Clothing Waste: The different processes like cutting, bundling, sewing, finishing, printing, embroidery, etc. result in scrap waste. Among all, the cutting section produces the maximum waste.

6) Solid Waste: The majority of this type of waste originates from other sources during operations like transportation, bale openings, servicing process and housekeeping. The waste under this category includes:

• Tubes, pallets, cones, containers, drums

• Plastic wrap, corrugated cardboard

• Seam waste, paper waste

• Bags, shipping cartons

7) Synthetic Fibres: Micro fibres may be less expensive than natural ones and easier to produce in large quantities. These synthetic fibres are mostly made of polyester, which is plastic and a by-product of petroleum. The process of changing petroleum into polyester is a long, toxic process. These fibres can take up to 200 years to decompose. Synthetic fibres are used in 72 per cent of our clothing. They pose health risks to consumers. Polyester is strongly linked to hormonal disruption and even for the formation of breast cancer cells. These are known to be non-degradable. Most of our waterways have become clogged with these and most fishes examined have been found to have synthetic nylon in their intestinal tract. Seabirds too have been found dead, and the cause of death is ingestion of synthetic fibres.

Rayon is made from processing of wood pulp. The technique may look safe and non-toxic, but it depletes huge volumes of wood from forests, causing an imbalance in nature. Polyester and nylon are the most commonly used synthetic textiles that are hazardous and made from petrochemicals. They create huge volumes of waste water, which is non-biodegradable and not eco-friendly. The production of nylon emits nitrous oxide, a greenhouse gas 300 times more dangerous than the ozone layer than carbon dioxide. Nylon is hard to recycle, making it hard to decompose, and therefore, leads to landfills. The replacement of more undyed natural fibres or materials dyed with natural dyes that are sustainable in nature should be prescribed as well as adopted.

8) Energy Utilisation Greenhouse Gas Emissions: Ten per cent of annual global carbon emission is generated by the apparel industry. Various types of greenhouse gases are emitted during the production, manufacturing and transporting of textiles. Synthetic fibres made from fossil fuels are making the industry very energy intensive. The solution is to choose natural fibres, to buy less, buy better quality, mend clothes and buy clothes made in countries powered more by renewable energy.

9) Soil Degradation: Soil is the fundamental component of the ecosystem and healthy soil helps in absorbing carbon dioxide. The depletion of soil nutrients leads to crops with low nutrition content leading to a human population with low immunity and various diseases. The fashion and textiles industries cause soil pollution. Excessive grazing by goats for their wool, adding excess chemicals to get textile fibres, deforestation for making rayon, are a few examples. The alternative is to use biodegradable textile fibres.

10) Rainforest Degradation: Every year, hectares of forest lands with enormous amounts of plantations and species are brought down by forest fire, or as a means of expansion for industrialisation. In addition to this, the trees are also explored for making rayon, modal and viscose, which are now replaced by lyocell.

Textile supplies the vital material essential for survival. Even though production involves pollution, it is important to shift to a circular economy in place of a linear economy. The waste generated in all stages ending up in landfills was common in the last century. Nowadays recycling, redesigning, upcycling, downcycling, restoring, repairing, reusing and reducing are some of the techniques used by the industry. Consumers should be aware of the choices they have and also try to become part of the sustainable chain. Green consumerism has changed the face of the textile industry, which is now recognised for its efforts taken to reduce wastage and infuse eco-friendly practices.

Comments