The garment industry is the biggest polluting industry which affects the whole world on a large scale. The pre-sampling and cutting of the fabric at manufacturing stage is the main source of pre-consumer fabric waste. This is all due to fast fashion. Inexpensive clothing produced by mass or bulk retailers according to the latest forecast and trend is known as fast fashion.

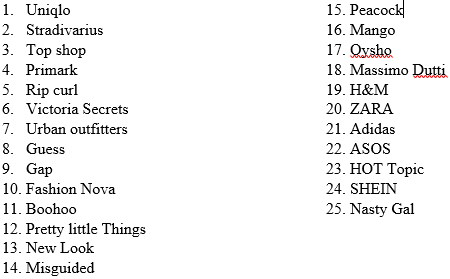

Brand involved in fast fashion are:

In this paper we will discuss how we can reduce industrial garment wastage by using virtual sampling i.e, 3D sampling and the type of software or techniques which can be used along with it.

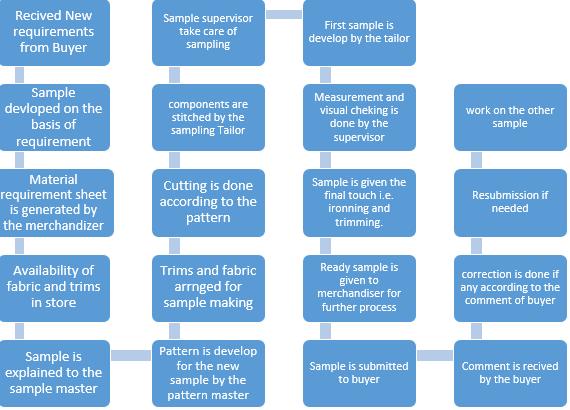

Process to develop garment in export house

Flow chart of an export house:

In the above flow chart, we can observe the flow of work and man force requirements of the garment industry. Other than this, there are a lot of different sampling work done in the export houses and buying houses which are as follows:

Proto sample /First sample

1. Fit sample

2. Size set sample

3. Salesman sample

4. Photo shoot sample

5. Development sample

6. PP sample

7. TOP sample

8. Counter sample

9. Shipment sample

10. Showroom sample

11. GPT sample

12. Gold seal sample /sealed sample

13. Red tag sample

14. Digital Garment Sample

The above mentioned process involves lot of rejections and recreation of the garments according to the comments of the buyer which results into lot of fabric wastage and developed sample wastage. Most of the time developed sample is sold to the local buyers like packman at half prices to be sold locally in the market and sometimes left over or rejected staple fabric is sold to the local craftsmen to develop new products from them like doormats, seat fillings, audio system padding, and many such useful products. But still lot of industrial scrap waste are left out.

According to the survey done by the Reverse Resources on Feb 1, 2021--about 80 per cent of recycalable waste does not get segregated by waste type in production and it needs to be sorted manually. 40 per cent of waste gets discarded due to mismatch with the buyer price, location or due to lack of market insight. Nowadays 70 per cent of balance post-industirial waste is used in a proper way to overcome this problem thanks to the collection and trading system but still we are not able to trace where the waste is ending up at.

To overcome this problem of the apparel industry, virtual 3D sampling is required or is invented to stop the wastage globally. So what do we mean by 3D virtual sampling?

3D virtual sampling

A new invention, the Virual 3D sampling and pre-production sampling will save the world from apparel and textile wastage. It is a new way to explore new design and concept before and after pre-production where we can save the bulk of fabrics and textile wastage. This new technology needs to be established and implemented worldwide.

The use of the 3D virtual sampling in the apparel industry is very important as it reduces the time-consumption, efficiency, and reduces the apparel and textile waste globally.

In current pandemic times, this is really a boon for apparel and textile industry as we can develop the design related to textiles, apparel, home furnishings etc with the help of this new technology. It helps buyers to visualise the collection and to imagine the same in actual fabric easily without any wastage in terms of fabric and investment done before the pre-production to develop different samples like pre-production sample, fit sample, newly developed sample etc.

Benefits of the technology are:

• Analyses the product

• Reduces the time in collection line development.

• Eliminates the process of actual fabric sample development.

• Quality of the design can be maintained

• Cost effective

• Product development efficiency can be increased

• Time reduction during the production stage

• Fit of the sample can be verified before the production

• Less rejection from the buyer at every stage.

• Less wastage

Conclusion

As per demands of the apparel industry, this new technology should get established in the apparel and textile industry to avoid wastage of leftover fibres, fabrics and developed samples of fabric. With the help of this technology our apparel industry can play its part to stop pollution globally. More industries should come forward and start implementing this technology.

Comments