We are already almost completely sustainable

Since 1972, Thermore has been on the leading edge in thermal insulation technology and continues to be a pioneer in the development of advanced fibres and innovative structures that help body maintain its natural warmth. Company’s spokesperson talks to Fibre2Fashion about thermal insulation and innovative outerwear products.

How has the thermal insulation market for apparel evolved in the last decade?

Customers have recently changed their purchasing behaviour and habits, and durability, eco-sustainability and a cruelty-free approach have now become crucial.

Despite the efforts of the apparel industry to move towards a more sustainable and cruelty-free approach, 10 years ago reputable surveys reported that 80 per cent of cold weather clothing was still insulated with duck feathers. This was mainly due to the lack of a synthetic solution that provided the same look and loft as down.

In 2018, Thermore took the first step towards free fibres by releasing a truly revolutionary and blowable product: Ecodown Fibers, 100 per cent recycled from post-consumer plastic bottles, providing amazing loft and luxurious touch as real down, thus meeting the market requirements over the last decade.

What is Thermore’s market share globally?

We are a worldwide leader specialised in research, development, production and marketing of high-quality thermal insulation for apparel.

Please tell us in detail about your latest offering EVOdown. What makes it unique?

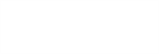

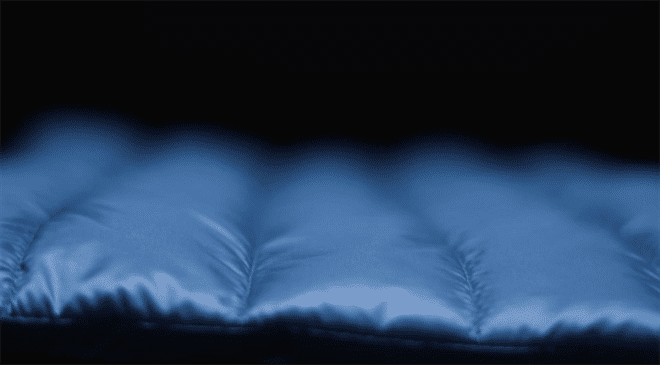

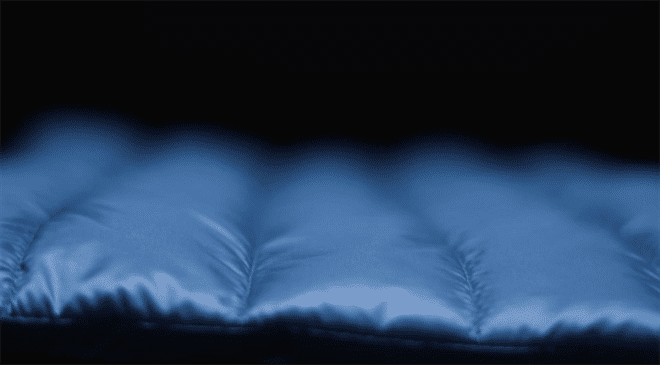

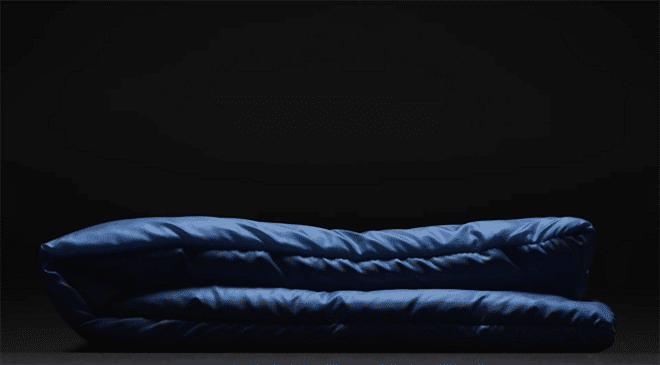

Thermore EVOdown bridges the gap between free fibres and traditional padding, delivering the ultra-soft hand and luxurious drape of blow-in fibres in a rolled form. This hybrid technology allows to boost productivity and ease of manufacturing.

In fact, EVOdown consists of millions of free fibres encapsulated by two containing outer layers, making it the world’s only product of this type.

Consumers will enjoy the lightweight and silky touch of EVOdown-made garments, as well as its unbeatable easy care.

Do you plan to include recycled PET in your other products too?

EVOdown Recycled is another step towards sustainability for us and we have now converted over 97 per cent of our turnover into insulations made of either fully or partially recycled fibres (based on actual sales figures). This brings us closer than ever to an exclusively sustainable product offer; and while the industry talks about future projects and roadmaps, we are already at the finish line being almost completely sustainable. This doesn’t come as a surprise: sustainability has always been part of Thermore’s DNA, as the Group pioneered the use of recycled fibres in the early 80s and mastered it thereafter.

Which are your major markets for thermal insulation in apparel? Which new ones do you plan to tap?

Through our global sales network and our productions in the Far East and in Europe, we cater to the best brands in the outerwear industry worldwide. Thermore products allow for unlimited designs to fulfil our customers’ needs, from fashion to sportswear.

What are the biggest challenges when it comes to providing thermal insulation for apparel?

This brand-new EVOdown has evolved to meet the specific needs of various markets and offers something for everyone. This has always been the biggest challenge indeed: providing the right product to fulfil most of designers’ requirements and even dreams. Just consider that also the Ecodown Fibers collection is an expanded offer that includes items providing amazing loft and visuals as well as extremely soft, yet ultra-light and highly packable free fibre insulations.

What new innovations, technologies and applications is Thermore currently working on?

We are currently working on the upcoming FW24/25. We have always been the technical leader in thermal technology. Sustainable technology is of key importance for us, and we plan to dedicate even more resources to the development of ‘green’ products in the coming seasons: eco-friendly products are at the forefront of our development initiatives for FW24/25 and beyond.

What has been your growth story in the last two years?

Despite the challenging times over the past two years, we have been keeping innovating. While the industry talks about future projects and roadmaps, we are almost completely sustainable with our brand new EVOdown. The pandemic – and all its related consequences – has been a chance for us in terms of research, development and opportunities.

What are the short-term and long-term plans at Thermore?

Talking about short-term plans, we firmly believe that blow-in fibres represent the future of the insulation market and using Thermore’s advanced technology and know-how is the key for the success of this category: this is now leading to the installation of another plant in Bangkok to keep up with demand (July 2022).

We are celebrating our 50th anniversary this year and the company is still defending its title as the global insulation specialist for apparel. Thermore’s team now includes young talents under the age of 30, which is what allows Thermore to stay ahead of the curve in the traditional environment of the textile industry. Established by Lucio Siniscalchi, Thermore now welcomes the third generation of the Siniscalchi family into the business, projecting the company into the future with some impressive and extremely innovative marketing activities in the long-term.