Part of manufacturing shifting from SE Asia to Europe

Switzerland-based Zünd Systemtechnik AG is a family-owned business with worldwide operations. It specialises in developing and manufacturing digital cutting systems and modular cutting systems since 1984. Segment manager, textile, Rolf Köppel, shares details on the latest trends and technologies dominating this industry.

What is the global market size for digital cutting systems for textiles? What is the average annual growth rate?

We cannot answer that in absolute numbers. Our internal research indicates an interesting market for us and therefore, we expand our focus to this segment.

Which is the most productive cutting solution in textiles, composites and technical textiles?

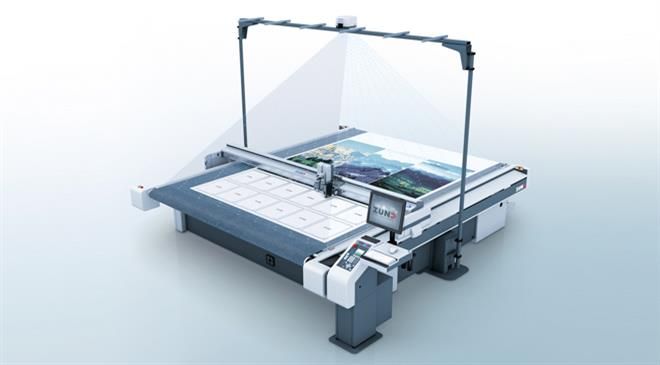

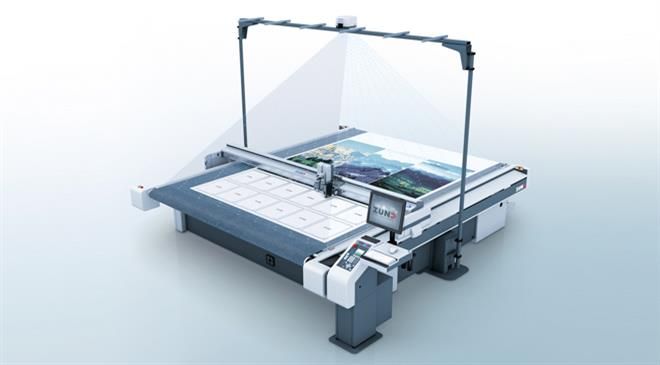

With the Zünd D3, we can offer manufacturers in these industries a cutting system that sets new standards in productivity. The extraordinary performance of the D3 is primarily due to the series' dual-beam construction: twin beams, equipped with up to three different modules, processing textiles simultaneously. Depending on the specifics of the job, this results in up to twice the throughput. The precision of the system's direct drive, combined with the latest software and controllers, ensures a highly efficient workflow from start to finish. The D3 series, just like the S3, L3 and G3, excels in terms of precision across the entire cutting surface, maximum modularity and user-friendly interface and control software. Because of the inherent flexibility of the system, the D3 is the perfect production solution for mass customisation.

What is the USP of your cutters?

Today's single-ply cutters must be very easy to integrate in a digital workflow. Only a complete, end-to-end production process gives users the flexibility and efficiency they need. Another important consideration is the ability to automate individual production steps. Zünd cutters are used in diverse applications, for example, in packaging and graphics. Particularly in these areas, many production processes have become largely digital and automated. Through our experience in these applications, we have gained a great deal of know-how when it comes to process integration. In these markets, flexibility, along with maximum individuality, is a must for any kind of production equipment. In response, we strive to continually adapt and upgrade our interface and workflow software, Zünd Cut Center ZCC, to meet the latest requirements.

At the same time, Zünd cutters can easily be integrated in existing software environments. Textile production is extremely heterogeneous, relying on a multitude of software environments, CAD programmes, and workflow solutions. In all these aspects, we are continually evolving our solutions and accommodating file formats that are common in this industry. This also allows us to generate and export to existing systems any relevant production data for post-production calculations.

How many digital cutters for textiles do you manufacture annually? Where are these manufactured?

As a family-owned business, we do not disclose our sales figures; nevertheless, our market research strongly indicates that we are the worldwide leader in cutting systems sold. All Zünd cutters are manufactured at the company headquarters in Altstätten, Switzerland.

Which are the top five markets for your products? Where do you see the potential increasing?

We sell and install cutting systems in over 100 countries worldwide. Our single highest-performing country is the United States, and the single best region is Europe in terms of units sold. With smaller batch sizes, shorter delivery times and a higher degree of customisation, we see a trend that manufacturing moves back closer to the customer. We see companies that moved their manufacturing 10 years ago to South East Asia are now moving back part of their production to Europe. With that trend, we also see a shift from multi-/high ply to single ply cutting. Expensive materials and technical possibilities in individualised digital printing are further fueling this trend.

What sustainability goals are set at Zund?

Sustainability is deeply rooted in our company DNA, and we take our social and our environmental obligations very seriously. Sustainability as a directive has been extended more and more over our entire value chain - from suppliers to resellers, as well as our own operations. Sustainability is, of course, especially important when it comes to the supply chain. That is one reason the vast majority of our suppliers are located within a 20-km radius of our production facilities. Three-quarters of the components that go into our cutting systems are supplied by these companies.

The proximity of key suppliers has another benefit: we can more closely monitor quality and obtain some components just in time. Over the last three years, we have delivered all cutters precisely on the date promised. We encourage all our customers overseas to select sea freight instead of air since that, too, helps reduce carbon dioxide.

Another particularly important issue for us and our customers is the reduction of waste, which we approach from a couple of different angles. Our software solutions and high-precision hardware are state of the art and designed to promote the careful use of resources, which is critical in markets that use expensive raw materials. In addition, highly advanced nesting functions optimise material usage and further help reduce waste.

What are your thoughts on Industry 4.0? Do you plan to integrate your systems with artificial intelligence (AI)?

Zünd cutters are also used in so-called smart factories. Two of the most important factors are horizontal and vertical integration, i.e. networking between machines and across different company divisions. Here Zünd, with its technical solutions, is already very far. It has enormous experience in the graphic segment, which is already highly integrated. Thanks to this know-how, Zünd Cutters can also be very easily integrated into existing workflows in the textile or leather sector.

Which are your top selling products?

Zünd cutting solutions are equally unsurpassed when it comes to cost of ownership. Zünd systems are known for their reliability and value retention, uptime and minimal maintenance costs. Because of the advanced level of modularity and automation they provide, Zünd cutters also significantly contribute to reducing labour costs.

What are the latest software innovations in digital cutters?

Integrating the digital cutting and optimising the production workflow relies strongly on how the software can handle data from the design to the final product. Zünd, with its open software system, enables the seamless integration and the Zünd Cut Center (ZCC) CAM software ensures the most efficient return from the Zünd cutting system.

What is the budget set for research and development R&D? What is the team currently working on?

We are always working on the next developments and innovations that will help our customers produce even more efficiently and cost-effectively. At our headquarters, we have a very strong R&D department with 45 employees, which corresponds to roughly a quarter of the total staff there. The key is not to concentrate on a single field of technology, but rather focus on dialogue with customers. Through these discussions, we can gain an understanding of the kind of technology that will benefit them the most. (HO)

What are the top three trends dominating the digital cutters industry?

Zünd works intensively and permanently on improving its cutting solutions. Key topics include automation for increased efficiency and performance, which increases capacities and reduces throughput times and versatility. The unique versatility of a Zünd Cutter increases flexibility and opens up new areas of application.