Interviews

QUT extracts polyester from polyester/wool mix fabrics

08 Dec '19

3 min read

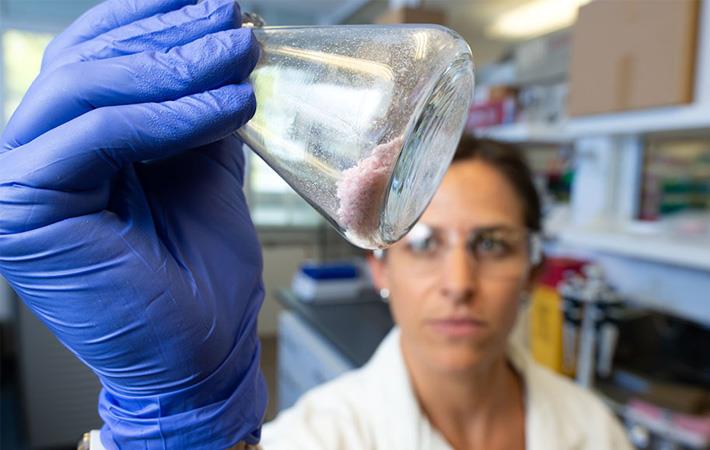

Pic: QUT the University

Scientists at Queensland University of Technology (QUT) have found a way to extract and reuse polyester from polyester/wool mix fabrics to help prevent some of the 92 million tonnes of textiles waste every year that goes to landfill. The team found a process to separate polyester from polyester and wool, and is now looking at scaling up the process.

The research has been published in Waste Management. Globally, an estimated 92 million tonnes of textiles go to landfill each year. Instead of being waste, recycled polyester is a high-value commodity with a marketing advantage.

Professor Robert Speight and Dr. Laura Navone found that a commercial enzyme dissolves wool fibres from polyester and wool mix fabrics, without damaging the polyester strands.

“Recycled polyester is a valuable tradable commodity,” Speight, from QUT’s Institute for Future Environments and the Science and Engineering Faculty, said. “The polyester extracted from fabric can be made into polyester chips and turned into anything from yarn for new textiles to playground equipment.”

“The value of recycled polyester has gone up significantly and gives clothing manufacturers a massive marketing advantage to be able to claim recycled material. Adidas, for example, has committed to using only recycled plastic by 2024 which includes polyester – contributing to the demand for recycled polyester,” Speight added.

Speight said the next phase was to partner with recycling companies to take the process to kilogram scale and understand more about the process design for commercial use and the economics.

Co-researcher Associate Professor Alice Payne, from QUT School of Design – Fashion, said Australians send 500,000 tonnes of textiles to landfill every year. “Australians discard an estimated $140 million worth of clothes each year with an average lifetime of three months for each item.”

“Polyester is incorporated in much of the 80-150 billion items of clothing made each year. It is favoured on its own or incorporated with natural fibres like cotton or wool because it is durable, light weight, easy-care with anti-wrinkle properties,” Payne said and added “These properties make it the fabric of choice for uniforms in such industries as banking, aviation and health.

“Separating and reusing polyester is part of the drive to prevent waste in the fashion industry. Other ways to prevent waste is to use clothing longer, buy second hand rather than new, and circulate, lend, borrow, repair, upcycle or resell no longer wanted clothing,” Payne said.

Payne said clothing collected by charities was resold in op shops, but also sold and exported to second-hand clothing markets around the world. “The resale market is growing much faster than the market for new clothing.”

The research has been published in Waste Management. Globally, an estimated 92 million tonnes of textiles go to landfill each year. Instead of being waste, recycled polyester is a high-value commodity with a marketing advantage.

Professor Robert Speight and Dr. Laura Navone found that a commercial enzyme dissolves wool fibres from polyester and wool mix fabrics, without damaging the polyester strands.

“Recycled polyester is a valuable tradable commodity,” Speight, from QUT’s Institute for Future Environments and the Science and Engineering Faculty, said. “The polyester extracted from fabric can be made into polyester chips and turned into anything from yarn for new textiles to playground equipment.”

“The value of recycled polyester has gone up significantly and gives clothing manufacturers a massive marketing advantage to be able to claim recycled material. Adidas, for example, has committed to using only recycled plastic by 2024 which includes polyester – contributing to the demand for recycled polyester,” Speight added.

Speight said the next phase was to partner with recycling companies to take the process to kilogram scale and understand more about the process design for commercial use and the economics.

Co-researcher Associate Professor Alice Payne, from QUT School of Design – Fashion, said Australians send 500,000 tonnes of textiles to landfill every year. “Australians discard an estimated $140 million worth of clothes each year with an average lifetime of three months for each item.”

“Polyester is incorporated in much of the 80-150 billion items of clothing made each year. It is favoured on its own or incorporated with natural fibres like cotton or wool because it is durable, light weight, easy-care with anti-wrinkle properties,” Payne said and added “These properties make it the fabric of choice for uniforms in such industries as banking, aviation and health.

“Separating and reusing polyester is part of the drive to prevent waste in the fashion industry. Other ways to prevent waste is to use clothing longer, buy second hand rather than new, and circulate, lend, borrow, repair, upcycle or resell no longer wanted clothing,” Payne said.

Payne said clothing collected by charities was resold in op shops, but also sold and exported to second-hand clothing markets around the world. “The resale market is growing much faster than the market for new clothing.”

Fibre2Fashion News Desk (SV)

Popular News

Leave your Comments

Editor’s Pick

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)