Interviews

News Flash

Browzwear launches 'Headless' Apparel Automation Engine

25 Jun '20

3 min read

Pic: Browzwear

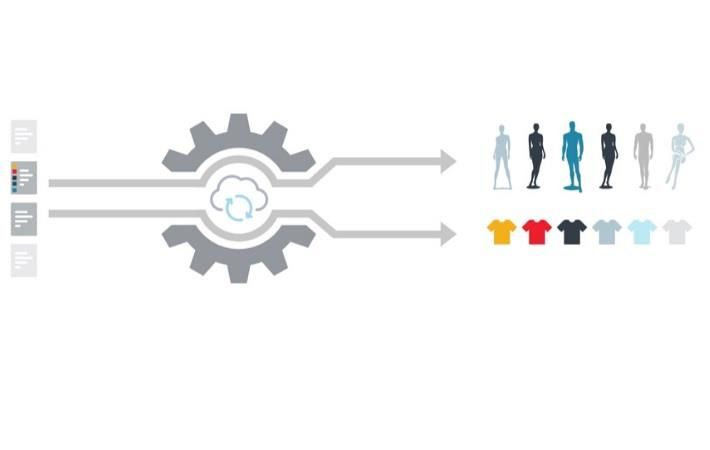

Browzwear has announced the launch of its 'Headless' End-to-End Apparel Automation Engine. The new solution enables organisations to use Browzwear’s pioneering 3D garment creation engine capabilities to power existing front-end applications and processes, to facilitate automation and support scale throughout the entire apparel production workflow.

The latest innovation from Browzwear, whose advanced technologies have been driving efficiency and sustainability in the apparel industry for over 20 years, builds on the integration-forward approach of the company’s Open Platform. Headless, a technology method in which the back-end is decoupled from the user interface side, enabling companies to develop customised solutions on top of Browzwear’s advanced technology to fit business and production needs, according to a media statement by the company.

Since the headless solution can be integrated with a host of technologies and automation functions, there are limitless internal and customer-facing use cases for the apparel industry such as: e-commerce, virtual try-ons, design iteration and creation, sizing, digital asset management, and more. To ensure the solution delivers on customers’ business goals, Browzwear will partner closely with each organisation, and help educate and consult about optimised implementation to maximise the value impact.

The solution can integrate with nearly any front-end application or framework. It can be built into a private cloud setup enabling top optimisation and max privacy. The solution can customised to meet the specific needs of each organisation. It also speeds/streamlines processes and facilitates demand and data driven supply chain production. The solution is optimised for unprecedented scale and gives the power to incorporate automation throughout the product development lifecycle.

Additionally, the Headless Engine frees employees from time-consuming and rote tasks so they can focus on their core competencies, from product conceptualisation to final production, and even merchandising.

“With Headless, processes across the entire organisation can be driven by script and code so they are completed automatically. After implementing the technology on the back end, designers are empowered to do things such as instantly create an endless number of colourways and generate true-to-life 3D renderings that can be used for design and line review, merchandise planning, and other GTM strategies such as ecommerce,” Noam Nevo, Browzwear’s co-founder and CTO said.

“Improving sales tools and shopping experiences is another example of a capability, long since on the fashion industry’s wish list, that is made possible by headless. By making everything faster, more accurate, and seamlessly executable, the technology holds immense potential for new direct to consumer sales tools and shopping experience based solely on a digital sample and an automated digital pipeline for the digital creation,” Avihay Feld, co-founder of Browzwear said.

The latest innovation from Browzwear, whose advanced technologies have been driving efficiency and sustainability in the apparel industry for over 20 years, builds on the integration-forward approach of the company’s Open Platform. Headless, a technology method in which the back-end is decoupled from the user interface side, enabling companies to develop customised solutions on top of Browzwear’s advanced technology to fit business and production needs, according to a media statement by the company.

Since the headless solution can be integrated with a host of technologies and automation functions, there are limitless internal and customer-facing use cases for the apparel industry such as: e-commerce, virtual try-ons, design iteration and creation, sizing, digital asset management, and more. To ensure the solution delivers on customers’ business goals, Browzwear will partner closely with each organisation, and help educate and consult about optimised implementation to maximise the value impact.

The solution can integrate with nearly any front-end application or framework. It can be built into a private cloud setup enabling top optimisation and max privacy. The solution can customised to meet the specific needs of each organisation. It also speeds/streamlines processes and facilitates demand and data driven supply chain production. The solution is optimised for unprecedented scale and gives the power to incorporate automation throughout the product development lifecycle.

Additionally, the Headless Engine frees employees from time-consuming and rote tasks so they can focus on their core competencies, from product conceptualisation to final production, and even merchandising.

“With Headless, processes across the entire organisation can be driven by script and code so they are completed automatically. After implementing the technology on the back end, designers are empowered to do things such as instantly create an endless number of colourways and generate true-to-life 3D renderings that can be used for design and line review, merchandise planning, and other GTM strategies such as ecommerce,” Noam Nevo, Browzwear’s co-founder and CTO said.

“Improving sales tools and shopping experiences is another example of a capability, long since on the fashion industry’s wish list, that is made possible by headless. By making everything faster, more accurate, and seamlessly executable, the technology holds immense potential for new direct to consumer sales tools and shopping experience based solely on a digital sample and an automated digital pipeline for the digital creation,” Avihay Feld, co-founder of Browzwear said.

Fibre2Fashion News Desk (GK)

Popular News

Leave your Comments

Therese Premler-Andersson

Textile Machinery Association of Sweden (TMAS)

Christian Guinet

French Textile Equipment Manufacturers’ Association (UCMTF)

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)