Interviews

OIST scientists trying to characterise Basho-fu

01 Jan '18

3 min read

Courtesy: oist.jp/Journal of Fiber Science and Technology, The Society of Fiber Science and Technology, Japan

Insights

- Researchers from Okinawa Institute of Science and Technology Graduate University (OIST), in collaboration with the University of the Ryukyus and the Kijoka Basho-fu Association, are trying to characterise Basho-fu materials, the traditional secret to keeping cool in subtropical island of Okinawa.

- Basho-fu is a textile fabric made from banana plant fibres.

Researchers from Okinawa Institute of Science and Technology Graduate University (OIST), in collaboration with the University of the Ryukyus and the Kijoka Basho-fu Association, are trying to characterise Basho-fu materials, the traditional secret to keeping cool in subtropical island of Okinawa. Basho-fu is a textile fabric made from banana plant fibres.

The team is also comparing traditional and laboratory Basho-fu production processes.

When Yoko Nomura moved from warm, dry California to the subtropical island of Okinawa, she was struck by the stifling heat and humidity. Searching for ways to survive the Okinawan summer months, Nomura, from the Science and Technology Group at OIST, discovered Basho-fu, an Okinawan textile fabric made from banana plant fibres. Originating from the 13th or 14th century, Basho-fu was used to make traditional Okinawan kimonos. Basho-fu kimonos were popular among all classes of people in the Ryukyu Kingdom, which ruled Okinawa from 1429 to 1879. Basho-fu textiles were highly durable for hard labour such as farming and fishing, and were comfortable to wear in the hot and humid subtropical climate of Okinawa.

The skill and expertise required to make Basho-fu textiles have been passed down through generations of craftspeople in Okinawa. However, the traditional craft is now under threat from a shortage of banana plant materials and an infiltration of modern methods.

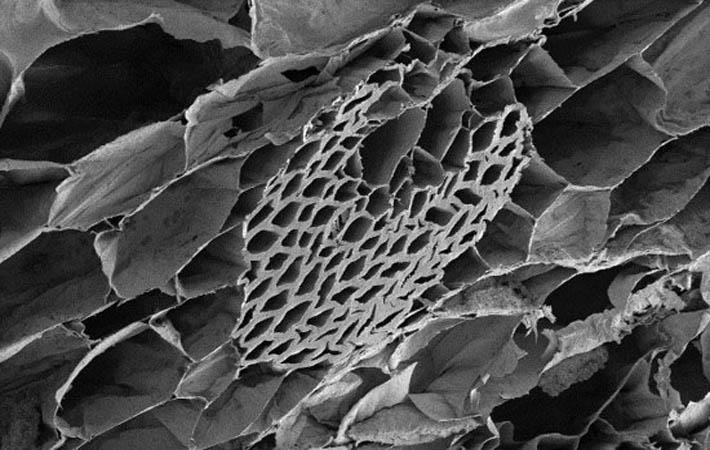

In their paper, recently published in the Journal of Fiber Science and Technology, the researchers used one of OIST’s Scanning Electron Microscopes to observe the structure of the Basho-fu materials in high-resolution. They also used other analytical techniques, such as X-ray diffraction, to investigate aspects of the chemical structure of the material, including crystallinity and molecular bonds.

“Our first finding was that the outer part of the harvested leaf sheaths, which is the part of the plant used to make Basho-fu textiles, contains many vascular bundles,” says Nomura, lead author of the paper. Vascular bundles are collections of conducting vessels used to transport water and nutrients in the plant. The presence of vascular bundles in Basho-fu material makes it highly breathable, keeping the wearer cool on hot days by allowing sweat to evaporate through pore-like structures.

“Next, we compared Basho-fu materials that had been made using the traditional degumming process with those made using modern laboratory methods,” says Nomura. Degumming is one of the refining steps in the long and complicated traditional Basho-fu production process. The researchers found that, although the vascular bundles remained in the material after both traditional and laboratory degumming processes, the laboratory-made materials were lower in quality.

Material that had been subject to laboratory degumming showed some additional changes compared with material that had been traditionally degummed. For instance, some of the vascular bundles in the laboratory-treated material were flattened, with fewer air voids. This shows that the traditional process of degumming is milder than the laboratory process, retaining more air voids and therefore maintaining greater breathability. Although the traditional method is more difficult and time-consuming, it is more delicate and produces Basho-fu textiles of better quality.

The next step is to analyse other features of the Basho-fu fibres and other steps in the long production process. Present and future studies of banana tree fibres will help to conserve the traditional Okinawan craft of Basho-fu, and may also aid the development of new textile materials. (SV)

The team is also comparing traditional and laboratory Basho-fu production processes.

When Yoko Nomura moved from warm, dry California to the subtropical island of Okinawa, she was struck by the stifling heat and humidity. Searching for ways to survive the Okinawan summer months, Nomura, from the Science and Technology Group at OIST, discovered Basho-fu, an Okinawan textile fabric made from banana plant fibres. Originating from the 13th or 14th century, Basho-fu was used to make traditional Okinawan kimonos. Basho-fu kimonos were popular among all classes of people in the Ryukyu Kingdom, which ruled Okinawa from 1429 to 1879. Basho-fu textiles were highly durable for hard labour such as farming and fishing, and were comfortable to wear in the hot and humid subtropical climate of Okinawa.

The skill and expertise required to make Basho-fu textiles have been passed down through generations of craftspeople in Okinawa. However, the traditional craft is now under threat from a shortage of banana plant materials and an infiltration of modern methods.

In their paper, recently published in the Journal of Fiber Science and Technology, the researchers used one of OIST’s Scanning Electron Microscopes to observe the structure of the Basho-fu materials in high-resolution. They also used other analytical techniques, such as X-ray diffraction, to investigate aspects of the chemical structure of the material, including crystallinity and molecular bonds.

“Our first finding was that the outer part of the harvested leaf sheaths, which is the part of the plant used to make Basho-fu textiles, contains many vascular bundles,” says Nomura, lead author of the paper. Vascular bundles are collections of conducting vessels used to transport water and nutrients in the plant. The presence of vascular bundles in Basho-fu material makes it highly breathable, keeping the wearer cool on hot days by allowing sweat to evaporate through pore-like structures.

“Next, we compared Basho-fu materials that had been made using the traditional degumming process with those made using modern laboratory methods,” says Nomura. Degumming is one of the refining steps in the long and complicated traditional Basho-fu production process. The researchers found that, although the vascular bundles remained in the material after both traditional and laboratory degumming processes, the laboratory-made materials were lower in quality.

Material that had been subject to laboratory degumming showed some additional changes compared with material that had been traditionally degummed. For instance, some of the vascular bundles in the laboratory-treated material were flattened, with fewer air voids. This shows that the traditional process of degumming is milder than the laboratory process, retaining more air voids and therefore maintaining greater breathability. Although the traditional method is more difficult and time-consuming, it is more delicate and produces Basho-fu textiles of better quality.

The next step is to analyse other features of the Basho-fu fibres and other steps in the long production process. Present and future studies of banana tree fibres will help to conserve the traditional Okinawan craft of Basho-fu, and may also aid the development of new textile materials. (SV)

Fibre2Fashion News Desk – India

Popular News

Leave your Comments

Editor’s Pick

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)