Interviews

News Flash

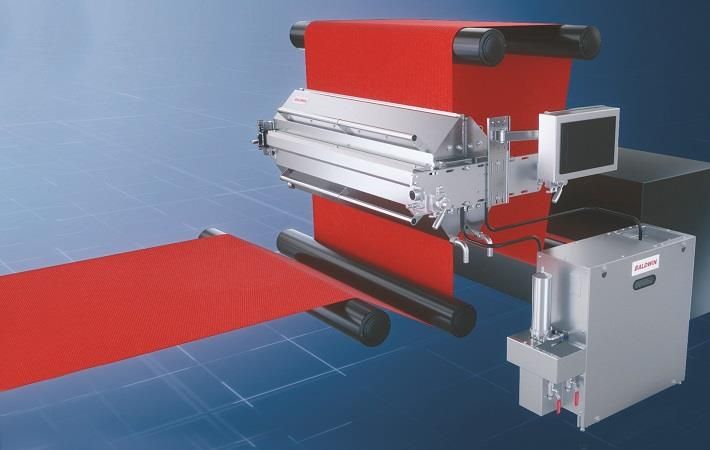

Sezginler Tekstil gets Baldwin's TexCoat G4 spray systems

18 Nov '20

3 min read

Pic: Baldwin's

Turkish knitted fabric printing and dyeing company, Sezginler Tekstil, has installed four of Baldwin Technology’s non-contact spray systems, TexCoat G4, to its softening finishing processes. It has reported that it is reaping the rewards of increased uptime, exceptionally even finishing quality, and considerably reduced chemistry and energy consumption.

Sezginler Tekstil was introduced to the finishing system by Turkish textile machine vendor, Spot Uluslararasi Tekstil, a partner of Baldwin. Baldwin is manufacturer and supplier of process-automation equipment and related consumables for textiles, printing, packaging and other industrial segments.

At that time, Sezginler Tekstil used the conventional pad/foulard method and experienced quality issues and time-consuming dilution occurrences, especially in the wet-on-wet softener process. By integrating Baldwin’s TexCoat G4 into this production step, finishing could now be accomplished wet-on-wet via pad/foulard followed by the non-contact spray system and eliminate the issues Sezginler Tekstil encountered with its existing system, according to a press release by Baldwin.

Convinced by the many benefits of applying finishing chemistry with non-contact spray technology, Sezginler Tekstil purchased a TexCoat G4 system for the stenter line in its softener finishing process. TexCoat G4 delivered immediate results, which led it to invest in three more of the systems. Sezginler Tekstil now uses the four non-contact spray systems in both wet-on-wet and wet-on-dry processes, which deliver high uptime, consistent quality, and practically zero chemistry waste.

“By using the TexCoat G4 in the wet-on-wet process with reactive dyed fabric, we get a uniformity of the fabric that we have never experienced before. Adding the non-contact spray technology to the pad/foulard, is a decision we will never regret. With TexCoat G4, we can totally rely on a continuous and even application from the first meter of the fabric to the last. The same amount of chemical concentration is applied throughout the production, which was never the case with the old finishing method, where every metre of the fabric could have variations as the pad/foulard also being dirtier each metre,” Ali Küçükerenköy, finishing manager at Sezginler Tekstil said.

The company also reported that its energy consumption for drying decreased by as much as 50 per cent in the wet-on-dry application, thanks to the TexCoat G4. The non-contact spray system allows for a higher concentration of chemistry mix with lower pick-up requirements. And with less wet pick-up, the fabric can pass through the stenter faster and with lower heat, reducing the energy consumption.

Rounding out the many advantages of Baldwin’s TexCoat G4 is the option of applying chemistry to one side of the fabric. This is of high value when running printed fabric, which Sezginler Tekstil regularly does, for avoiding unwanted pigmentation on the prints or when running fabric with one-sided finishing characteristics. Additionally, applying chemistry on just one side is significantly more cost-effective since the chemistry consumption will be 50 per cent less compared to a dual-sided application.

Sezginler Tekstil was introduced to the finishing system by Turkish textile machine vendor, Spot Uluslararasi Tekstil, a partner of Baldwin. Baldwin is manufacturer and supplier of process-automation equipment and related consumables for textiles, printing, packaging and other industrial segments.

At that time, Sezginler Tekstil used the conventional pad/foulard method and experienced quality issues and time-consuming dilution occurrences, especially in the wet-on-wet softener process. By integrating Baldwin’s TexCoat G4 into this production step, finishing could now be accomplished wet-on-wet via pad/foulard followed by the non-contact spray system and eliminate the issues Sezginler Tekstil encountered with its existing system, according to a press release by Baldwin.

Convinced by the many benefits of applying finishing chemistry with non-contact spray technology, Sezginler Tekstil purchased a TexCoat G4 system for the stenter line in its softener finishing process. TexCoat G4 delivered immediate results, which led it to invest in three more of the systems. Sezginler Tekstil now uses the four non-contact spray systems in both wet-on-wet and wet-on-dry processes, which deliver high uptime, consistent quality, and practically zero chemistry waste.

“By using the TexCoat G4 in the wet-on-wet process with reactive dyed fabric, we get a uniformity of the fabric that we have never experienced before. Adding the non-contact spray technology to the pad/foulard, is a decision we will never regret. With TexCoat G4, we can totally rely on a continuous and even application from the first meter of the fabric to the last. The same amount of chemical concentration is applied throughout the production, which was never the case with the old finishing method, where every metre of the fabric could have variations as the pad/foulard also being dirtier each metre,” Ali Küçükerenköy, finishing manager at Sezginler Tekstil said.

The company also reported that its energy consumption for drying decreased by as much as 50 per cent in the wet-on-dry application, thanks to the TexCoat G4. The non-contact spray system allows for a higher concentration of chemistry mix with lower pick-up requirements. And with less wet pick-up, the fabric can pass through the stenter faster and with lower heat, reducing the energy consumption.

Rounding out the many advantages of Baldwin’s TexCoat G4 is the option of applying chemistry to one side of the fabric. This is of high value when running printed fabric, which Sezginler Tekstil regularly does, for avoiding unwanted pigmentation on the prints or when running fabric with one-sided finishing characteristics. Additionally, applying chemistry on just one side is significantly more cost-effective since the chemistry consumption will be 50 per cent less compared to a dual-sided application.

Fibre2Fashion News Desk (GK)

Popular News

Leave your Comments

Editor’s Pick

Pratik Gadia

The Yarn Bazaar - Filosha Infotech Private Limited

Andreas Rass

ZIMMER AUSTRIA | Digital Printing Systems

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)