Interviews

Nano Camouflage outfits for fashionistas & environmentalists

23 Apr '09

5 min read

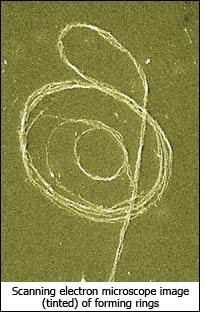

Scanning electron microscope image (tinted) of forming rings

The traveling microtubules are coated with quantum dots — nanoscopic groups of atoms that emit light, their frequency dependent on dot size.

The dots emit different frequency of light than they adsorb, while the biological system merely reflects incoming wavelengths. But they perform similar coloring functions.

The telephone cord twist

When motor-transported microtubules collide, the microtubules stick together and twist until they resemble a desk phone cord. The twisting process ultimately forces the formation of stable rings approximately five micrometers in diameter. Their docked quantum dots (cadmium selenide) produce a range of light frequencies.

When mechanical strain in the rings causes them to rupture, the cracked segments are tugged out by the nearby motors until the ring is completely disassembled. The formation and destruction of the two states — free microtubules and rings — can be reversibly controlled.

Thus the dots can be tightly packed or dispersed — optically, an essential ingredient in the perception of color change.

Mimicking fish

The process resembles the action of fish color changes, which require one group of motor proteins carrying pigments to be “on” all the time while a second group of motor proteins is turned on by complex biological processes at the right time. This produces a tug-of-war between motor groups that results in pigment dispersion and ultimately a color change. When the second motor is switched off, the color returns to the ground aggregate state.

“Our overall process mimics the fish,” says Bachand. “We essentially go from a dispersed particle state to a concentrated one and then back again to dispersed, similar to the fish. Thus, in principle, the mechanism could produce a color change. The underlying science provides a new basis for materials scientists to begin working toward real-world applications.”

The work was supported by DOE Basic Energy Sciences and Sandia's Laboratory Directed Research & Development office.

Key contributors to the Biotechnology & Bioengineering paper were Adrienne Greene and Amanda Trent (now a graduate student at University of California, Santa Barbara). Advanced Materials paper contributors were Haiqing Liu (now at Los Alamos National Laboratory), Erik Spoerke, Marlene Bachand, Steve Koch (former Sandia employee, now an assistant professor at the University of New Mexico), and Bruce Bunker.

The dots emit different frequency of light than they adsorb, while the biological system merely reflects incoming wavelengths. But they perform similar coloring functions.

The telephone cord twist

When motor-transported microtubules collide, the microtubules stick together and twist until they resemble a desk phone cord. The twisting process ultimately forces the formation of stable rings approximately five micrometers in diameter. Their docked quantum dots (cadmium selenide) produce a range of light frequencies.

When mechanical strain in the rings causes them to rupture, the cracked segments are tugged out by the nearby motors until the ring is completely disassembled. The formation and destruction of the two states — free microtubules and rings — can be reversibly controlled.

Thus the dots can be tightly packed or dispersed — optically, an essential ingredient in the perception of color change.

Mimicking fish

The process resembles the action of fish color changes, which require one group of motor proteins carrying pigments to be “on” all the time while a second group of motor proteins is turned on by complex biological processes at the right time. This produces a tug-of-war between motor groups that results in pigment dispersion and ultimately a color change. When the second motor is switched off, the color returns to the ground aggregate state.

“Our overall process mimics the fish,” says Bachand. “We essentially go from a dispersed particle state to a concentrated one and then back again to dispersed, similar to the fish. Thus, in principle, the mechanism could produce a color change. The underlying science provides a new basis for materials scientists to begin working toward real-world applications.”

The work was supported by DOE Basic Energy Sciences and Sandia's Laboratory Directed Research & Development office.

Key contributors to the Biotechnology & Bioengineering paper were Adrienne Greene and Amanda Trent (now a graduate student at University of California, Santa Barbara). Advanced Materials paper contributors were Haiqing Liu (now at Los Alamos National Laboratory), Erik Spoerke, Marlene Bachand, Steve Koch (former Sandia employee, now an assistant professor at the University of New Mexico), and Bruce Bunker.

Sandia National Laboratories

Popular News

Leave your Comments

Editor’s Pick

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)