SupplyCompass launches production platform of future

The launch makes SupplyCompass a first of its kind platform, enabling fashion brands and manufacturers to build strong partnerships and work together as one team—collaborating more effectively, bringing collections to market faster and producing better quality products. Fashion brands can also still tap into a vetted manufacturer network when they need new manufacturing partners.

"The pressure on fashion brands today is greater than ever to deliver fresh, high quality, sustainably made products fast, at an affordable price. Delivering on all of these can be challenging, with too much time often spent managing orders, a lack of control and visibility on orders, fragmented comms and information sharing and inconsistent product quality – all whilst facing resource pressures and a need for faster lead-times to launch new products," said Flora Davidson, head of Product and co-founder of SupplyCompass.

“To manage their fashion production, most fashion brands are still using a mix of Excel, email, WhatsApp and legacy PLM systems. Many of these are either not designed for the complex needs of fashion production, or they are outdated, clunky to use and don’t facilitate effective cross-organisation work. Add to the mix COVID-19’s long-lasting impacts on global supply chains plus distributed teams, and 2020 demonstrated that fashion businesses can no longer afford to work in the old way. Supply chains need to become reactive, agile and efficient to survive," Davidson added.

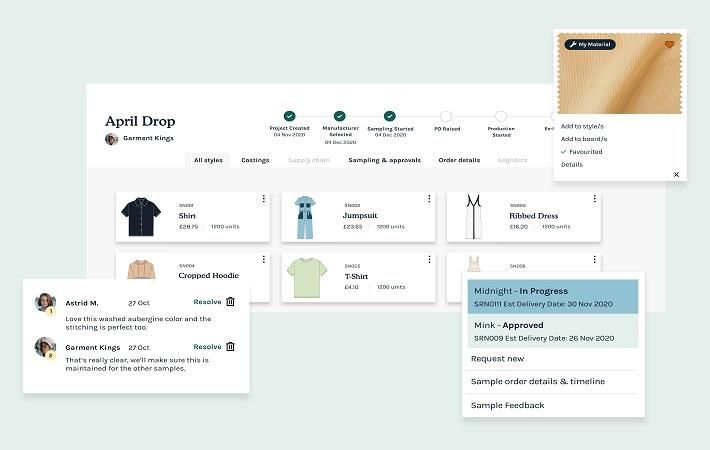

SupplyCompass' Production Platform is a new type of fashion software that enables brands to develop products and manage their production process, with their manufacturers, all in a single place. From sharing inspiration in moodboards, standardising and better visualising tech packs, comparing and tracking costing, building digital libraries, to developing greater feedback traceability, with SupplyCompass, brands reduce uncertainty and gain greater control, saving time and costs (up to 70 per cent less time spent managing production).

The product update means fashion businesses can now invite and onboard their own factories and suppliers onto the platform, allowing them to better collaborate on and manage the extensive production process and giving them the ability to manage their whole supply chain network via a single source of truth. While brands can still gain instant access to new trusted and vetted manufacturers through SupplyCompass should they need, the ability to bring on board brands’ existing factories now makes it possible for brands to use the platform across all orders and their entire supply chain business.

The result is, through SupplyCompass, brands can design better products, bring collections to market 50 per cent faster with increased sample hit rate and less stress and uncertainty, as well as focus on building stronger supply chain relationships. With standardisation across countries, languages and varying levels of expertise, teams will be empowered to spend less time managing production, and more time creating value elsewhere in the business.

With the new SupplyCompass chat feature, brands can now: upload heavy files directly into the chat, with no restrictions on file size like emails; have team chats unrelated to projects, whilst having a tool that encourages users to link conversations to a project, so all conversations about that order happen together; communicate in real-time with their factories, with the key difference being that all conversations relating to each order are saved in one single thread, and with all the relevant team members from both brand and manufacturer having visibility; and share videos, embed links, and use emojis - to bring personality and humanness to messaging, nurturing the partner relationship.

"This is our most exciting product update yet – one that has been four years in the making. Ever since our two-year stint in India, we’ve seen first-hand the problems facing the fashion industry, but 2020 just skyrocketed these. As we’re in a unique position at SupplyCompass — bridging the gap between brands and manufacturers — we knew we had to act fast and provide better software for fashion production. This meant opening our platform up for brands to bring on board their own factories, facilitating collaboration and strengthening existing partnerships," said SupplyCompass CEO & co-founder Gus Bartholomew.

"Ultimately we believe now is the time for brands to recognise manufacturers as part of their business. And this is why we also developed our chat feature, which brings brands and factories closer together, to produce better. Historical chat tools have allowed too much freedom for new channels and threads for something like production, which needs structured communication if it’s to truly work. We’re hugely excited to roll-out our new features, which will help brands launch categories faster, design for sustainability, gain visibility, spend less time stressed about production, and reduce uncertainty," he added.

“After dealing with factories for a few years where we faced constant issues with lead times, quality, corner-cutting and a lack of transparency, SupplyCompass have provided a massive breath of fresh air. The platform makes creating products easier than I could have possibly ever imagined a few years ago,” said Giles Campbell Longley, founder of parkour and streetwear brand The Motus Projects.

“Having production information and communication all in one place saves me and my team a lot of time, and really helps reduce the amount of communication back and forth. It has helped us to improve quality and just generally make our service better. Plus, it’s super quick and easy to learn—I love it!" said Jambu, owner of a GOTS certified jersey factory in India.

When it comes to sustainability, SupplyCompass has found many businesses struggling to gather fast, reliable, detailed data on their supply chains. For teams using the platform, SupplyCompass provides a digital core to production, meaning brands can start to gather critical product, supply chain and order data from across their organisation - in a few clicks.

"Our long-term vision is for SupplyCompass to facilitate impact scoring, to support teams to build sustainability metrics into the process from the get-go. In addition, with all brands’ manufacturers and suppliers working from one single system, it will better allow traceability to be baked into supply chains. The future has to be circular, and the success will depend on elegant systems that make this easy for brands and suppliers,” concludes Davidson.

Fibre2Fashion News Desk (RKS)

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)