Garment washing processes cancause severe damages to zippers. Avoiding common mistakes and taking certainimportant measures can help prevent these damages.

Different types of technologiesare used in garment washing to achieve specific purposes such as smoothness,brightness, softness, aged or faded look, outlook modifications and more. Theseprocesses differ from the normal washing procedure that depends on factors likewashing temperature and time, quantity of the detergent used and more.

The main kinds of garment washingtechniques are:

BleachWash

Bleach washing is carried out toachieve the colour fading effect and is usually meant for garments dyed withdirect or reactive dyes. Oxygen Bleaching, a type of bleach washing technique,produces whitening and faded effect with the oxidation of aquae hydrogeniidioxide under specific temperature and PH value to destruct the dye structures.Chlorine Bleaching can also be used to achieve the faded look with oxidisingsodium hypochlorite to destruct the dye structures.

EnzymeWash

Enzyme wash is another techniquemeant for denim, jeans and other heavy fabrics. It makes use of celluloseenzyme under specific temperature and PH value for degrading the fibrestructures to gently remove colour and get a peached and soft effect.

StoneWash

A popular washing technique, stonewashing is usually applied to heavy fabrics like denim and jeans. Essentiallyused for getting the worn-out or aged look, the washing technique could havesome adverse effects on the garment. It could result in irregular colour fadingor even garment shrinkage among other things.

MonkeyWash

This is another type of wash thatproduces the fading effect. It involves the usage of potassium hypermanganatein combination with oxalic acid.

Sand Wash

Meant to achieve the aged or fadedlook, sand wash is carried out using basic and oxidising auxiliaries. Softeningagents are added during this wash to help maintain the comfort and softness offabrics.

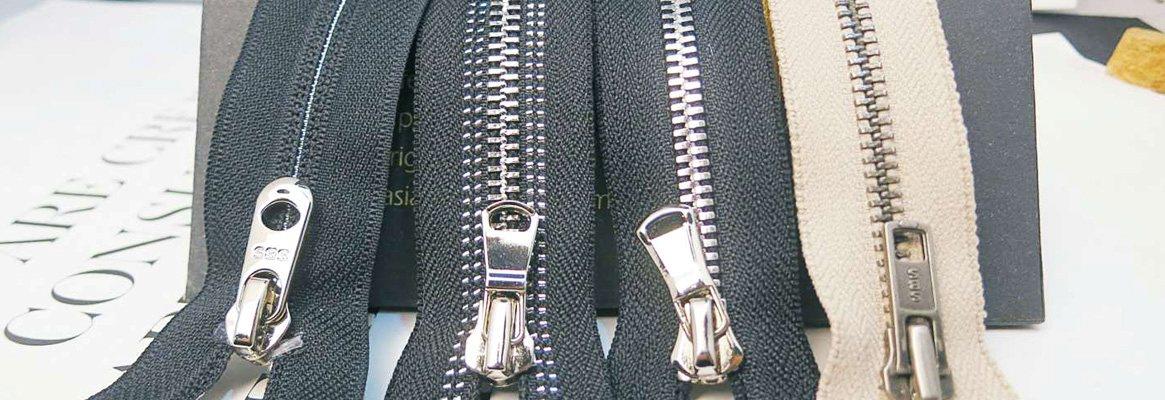

Protectingzippers during garment wash

If utmost care isn't taken whilegarment washing, zippers can end up being damaged. This could reduce theirservice life, even if they have been made using high quality materials.

Potential problems & effective measures to avoid damages to zippers

Mechanical Damage

-

Not zipping up the zippers during the washing procedure might cause damages to zipper parts such as zipper teeth, retainer box and pin.

-

Sliders left mid-way during the washing procedure cause the sliders, bottom stops and other elements of the zippers to undergo stress, thus damaging them. Some sliders can also end up falling into the drain hole of the drum used for washing garments, causing zipper pulls to break or get distorted and causing crampers to detach.

-

Friction and collision in between zippers and the washing drums can end up bringing abrasion to zipper teeth and sliders. It can cause paint or coating of the zippers to peel off.

Chemical Damage

-

Zippers made of aluminium react chemically during the washing process, thus causing the zipper teeth to break and fall off.

-

It is necessary to cleanse and dry garments after washing them to avoid the oxidation-reduction reaction between the zippers' metallic parts and the fabric dyes or residual chemicals. This could cause the metal elements of the zippers to lose their original colours.

-

Oxidation of brass alloy zippers used on metallic or woollen products cause zipper teeth to turn black due to the reaction between the teeth and the chemical residue on the product surface.

Tips to avoid zipper damage during garment wash

Please follow the tips below when you are using sbs zippers to help avoid damages to the accessories during the garment washing process.

-

Use laundry bags prior to washing, turn the garment inside out and zip it up

-

Close zippers completely and lock the sliders into position before starting the washing process. A pin can be used to fasten the zipper if it tends to unzip during the process

-

Avoid friction, abrasion or collision by wrapping up the zipper teeth and sliders

-

Prevent puller and slider to collide with hard surface of the washing drums

-

Cleanse and dry garments after the washing process

-

Carry out sample washing to test the results before washing garments in bulk

References:

1. Sbs-zipper.com

Comments