The growinginventory is proving to be a hurdle especially when we move upward in thesupply chain, says

Is your supply chain characterised by problems like lackof communication, disorganisation, delay in order decisions and demand and supplygaps? You could be facing the dreaded bullwhip effect.

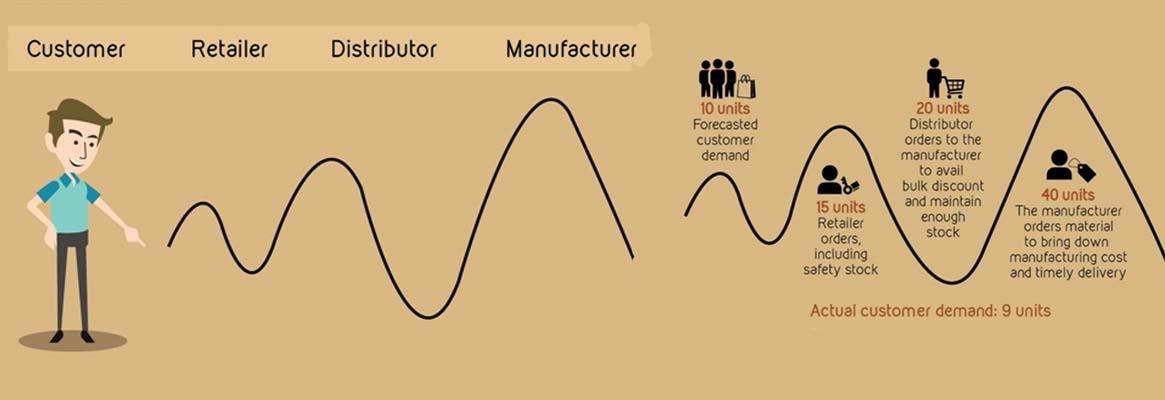

The order that the manufacturer receives is often muchlarger than what the actual customer's demand is, at the point of sale. Thisirregularity or variance in the size of the orders placed, increases as we moveup the supply chain, i.e. from the customer to the retailer to the distributor,and then to the manufacturer. So downstream, there is a flow of physical goodsand upstream, a flow of demand information.

Eventually, 40 units were produced against a demand ofnine units. The inventory will be pushed to the customer through offers anddiscounts and more investment will be made for the product's marketing andadvertising efforts.

This effect was observed by executives of Procter andGamble (P&G). Sales patterns for one of their best-selling products,Pampers, fluctuated in retail stores but the variabilities were not excessive.However, as they examined the distributor's orders, the degree of variabilityincreased. When they further looked at P&G's orders of materials to theirsuppliers, they discovered that the swings were even greater. This did not makesense. While consumers --- babies --- used diapers at a steady rate, the demandorder variabilities in the supply chain were amplified as they moved up thesupply chain.

In a supply chain for a typical consumer product, evenwhen consumer sales do not seem to vary much, there is pronounced variabilityin retailers' orders to wholesalers. Orders to the manufacturer and to themanufacturer's supplier spike even more. To solve the problem of distortedinformation, companies need to first understand what creates the bullwhipeffect so they can counteract it.

Behind the bullwhipeffect

While the lack of information sharing is the most obviousreason, there are four identified causes of this whiplash effect:

1. Demand forecast updating: Every company in a supplychain follows product forecasting which is usually based on past order history.This helps in scheduling production, planning material requirement, control ofthe inventory and planning capacity. In this case, fluctuations are notaccounted for. Also, the lead time of the orders varies or fluctuatesdrastically in some cases, which might force the buyer to place bigger orders.

For example, if you are a manager who has to determine how much to order from a supplier, you use a simple method for demand forecasting, such as exponential smoothing. With exponential smoothing, future demands are continuously updated as new daily demand data becomes available. The order you send to the supplier reflects the amount you need to replenish stocks to meet requirements of future demands, as well as necessary safety stocks. Future demands and associated safety stocks are updated using the smoothing technique. With long lead times, it is not uncommon to have weeks of safety stocks. The result is that the fluctuations in order quantities over time can be much greater than those in the demand data.

Now, one site up the supply chain, if you are the manager of the supplier, the daily orders from the manager of the previous site constitute your demand. If you are also using exponential smoothing to update your forecasts and safety stocks, the orders that you place with your supplier will have even bigger swings. Because the amount of safety stock contributes to the bullwhip effect, it is intuitive that, when the lead times between the resupply of the items along the supply chain are longer, fluctuation is more.

2. Order Batching Practice: Larger order sizes often offer discounts and lower cost advantages to the buyer, or at times suppliers do not entertain smaller order sizes. Hence, companies tend to accumulate demand to reach a respectable order size and order monthly or weekly, which creates demand variability as average demand is not stable across the time period.

Consider a company that orders once a month from its supplier. The supplier faces a highly erratic stream of orders. There is a spike in demand at one time during the month, followed by no demands for the rest of the month.

If the majority of companies that use MRP or distribution requirement planning (DRP) to generate purchase orders do so at the beginning or the end of the month, order cycles overlap. Periodic execution of MRPs contributes to the bullwhip effect, MRP jitters or DRP jitters.

3. Pricing Fluctuations and Trade promotions: Specific period discounts, or cost fluctuations, can lead buyers to order in bulk to avail of discounts which cause demand variability in the supply chain.

Estimates indicate that 80 per cent of transactions between manufacturers and distributors in the grocery industry were made in a "forward buy" arrangement in which items were bought in advance of requirements, usually because of a manufacturer's attractive price offer. Forward buying constitutes US$ 75 billion to US$ 100 billion of inventory in the grocery industry.

4. Rationing and short gaming: When product demand exceeds supply, a manufacturer often rations products to customers. For example, the manufacturer then allocates products in proportion to the amount ordered by different retailers. In turn, retailers often anticipate potential shortages by exaggerating real needs when they order. If demand drops later, this will lead to small orders and cancellations. Lee et al [2] call this overreaction by customers, rationing, and shortage gaming. This "gaming" results in misleading information on the product's real demand.

One example is the shortage of Dynamic Random Access

Memory or (DRAM) chips in the 1980s. In the computer industry, orders for these

chips grew fast not because of a growth in customer demand but because of

anticipation. Customers placed duplicate orders with multiple suppliers and

bought the first one that could be delivered. Then they canceled duplicate

orders.

More recently, Hewlett-Packard could not meet the demand

for its LaserJet III printer and rationed the product. Orders surged, but HP

managers could not find out whether the orders genuinely reflected real market

demands or were simply phantom orders from resellers trying to get a better

allocation of the product. When HP lifted its constraints on resupply of the

LaserJets, many resellers canceled orders. HP's costs in excess inventory after

the allocation period and in unnecessary capacity increases were in millions of

dollars.

Controlling

measures:

The only way to counter the bullwhip effect is to have

accurate, real-time demand information. For that, we need to shift from a

forecast-driven ordering system to measures that allow information sharing with

supply chain partners and hence complete visibility of actual customer demand.

Some common measures that companies are following globally to counter the

bullwhip effect and establish a demand-driven supply chain are the Kanban

system, vendor managed inventory, strategic supply chain partnerships, lean

management, real-time information sharing, and just in time inventory

replenishment system.

Incorporating one or more of these systems and management

philosophies, we can counter the bullwhip effect in our supply chain and form

better long-term strategic partnerships.

About the author:

Mausmi Ambastha holds a Master's degree in Fashion

Technology from NIFT, Delhi and did her Bachelor's in Engineering in Computer

Science. She has over 13 years of experience in the garment industry. She is a

founder and chief operating officer of ThreadSol.

Reference:

1. J. W. Forrester. Industrial dynamics. MIT Press,

Cambridge, MA, 1961.

2. H. L. Lee, V. Padmanabhan, and S. Whang. The bullwhip

effect in supply chains. Sloan Management Review, 38(3), 1997

3. Salmon (1993).

4. P. Sellers, "The Dumbest Marketing Ploy," Fortune, volume 126, 5 October 1992, pp. 88-93.

Comments