Ashok Athalye offers a peek into waterproofing techniques for shoelaces.

Shoestring or shoelace is a small but significant part of most footwear. Various types of shoes used in formal wear, sports and athletics are firmly worn using a shoestring.

The global footwear market, estimated to be about $250 billion in 2017, is expected to cross $300 billion by 2020. China and India manufacture and export over 80 per cent of the global footwear requirements. Shoes constitute about 70 per cent of the global footwear market.

The growth driver for the shoemaking industry is the increasing health awareness that is generating a higher demand for athletic footwear while changing lifestyles and rising number of working professionals are leading the demand for formal footwear. Further, the rapid growth is attributed to the large population shift from rural agrarian culture to the urban industrial and service-oriented society.

The growth driver for the shoemaking industry is the increasing health awareness that is generating a higher demand for athletic footwear while changing lifestyles and rising number of working professionals are leading the demand for formal footwear. Further, the rapid growth is attributed to the large population shift from rural agrarian culture to the urban industrial and service-oriented society.

Historical evidence of use of shoes dates back to the Copper Age about 8,000 years ago. Initially, shoes were made of animal skin or material derived from plants and stitched by hand. The mechanised shoemaking industry developed in the early 19th century and shoes were made from leather, wood or canvas. More number of shoes are now being made from rubber, plastics and other polymeric materials.

Thus the selection of raw materials and the process of shoemaking are based on its use as an item intended to protect and comfort the human foot or ensure aesthetics for its use a fashion item. The design of shoes varies widely in style, complexity and cost and also according to the region's weather.

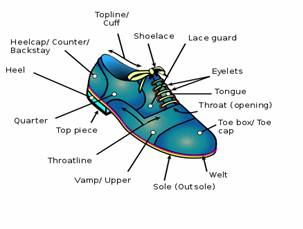

Shoe components

Depending on the type of show and its intended use, it is made up of about 15 to 17 components depending on size and design, starting from the outer sole at the bottom to the shoelace on the upper part. Some shoes have straps with buckles, zippers, elastic and Velcro or buttons used for tightening the upper on the foot. However, the majority of shoes have a complex upper decorated or made in a style to look attractive with coloured or designed shoestrings. The aesthetic appeal is enhanced by incorporating different methods of lacing, the most common being crisscross lacing and lace knotting.

Shoestrings are commonly used to secure shoes on human feet. They consist of a pair of strings or cords, one for each shoe. Traditional shoestrings were made of leather, hemp, cotton or jute. Nowadays shoelaces are made of synthetic fibres like nylon, polyester and polypropylene. Thus, shoestring is the only textile fibre-based component used in the entire shoemaking process.

The colouring of the shoestring depends on the colour of the shoes, which are mostly black or brown in case of formal wear. However, in case of casual or athletic shoes, coloured shoestrings are used that either match or are in contrast to the colour of the shoes to enhance the fashionable look. Accordingly, the material is dyed depending on the shoestring textile fibre composition.

The size and shape of shoestrings also vary, the most common being the flat cross-section, followed by a round shaped and braided ribbon type.

The major functional requirement of shoestrings is to be hydrophobic and waterproof. Rain or wet ground or grass can dampen the shoestrings and the dampness seeps into the socks and the inner part of shoes making the wearer uncomfortable. At the same time, the

Waterproofing is the most important effect desired on shoestrings. The objective is to reduce the critical surface tension of the textile component below the surface tension of water. This increases the internal cohesive strength of water over the external attraction exerted by the textile. Such surface coating or finishing prevents wetting of the shoestring.

Various finishing chemicals are used for imparting varying extent and durability of water repellency. Some of the commonly used chemicals to achieve this effect are waxes, polyacrylates, poly-siloxanes, fluoro-polymers and dendrimers.

Coating of shoestrings with paraffin wax is the oldest and most economical way of imparting water repellency. However, it is only water repellent, implying it only tends to resist wetting and surface spreading of water but allows its permeation on prolonged contact. It does not meet the desired requirement of waterproofing, which is not allowing water permeation even under prolonged contact. Polysiloxanes impart a soft shiny feel in addition to water repellency and have improved durability compared to wax coating but also exhibit moderate waterproofing.

Fluoropolymers are considered to be the best for their waterproofing ability as well as ensuring durability but are also the most expensive chemicals for this purpose. The cost of these chemicals depends on the manufacturing process like oligomerization, electro-fluorination and telomerization as well as the extent of associated carbon chain length like C8-octane and C6-hexane. However, these chemicals have toxicity concerns, though their application and usage on shoestrings does not come in contact directly with the skin for a prolonged time and therefore, may not be a major issue.

A novel and patented dendrimer-based technology called Bionic finish is now being evaluated for achieving sustainable, eco-friendly, cost-effective waterproofing of shoestrings. Dendrimers are highly branched oligomers with non-polar chains forming a starbrush structure that does not allow a water molecule to remain on the textile surface. Additionally, it imparts high abrasion resistance, wash durability and soft handle. The shoestrings are dipped or passed through the chemical bath at room temperature. The excess chemical is squeezed off the surface and subsequently it is dried at about 110-120 0C followed by curing at 170- 180 0C.

About the author: Ashok Athalye works with the colours business of Atul Ltd in Valsad, India.

Comments