Relentless cost pressure remains a major concern for the textile industry. The reasons for this are numerous, and include the steadily rising costs of energy, water, and effluent treatment. This is especially an issue for the production of woven fabrics that consist of blends of polyester and cellulosic fibres such as cotton and viscose and elastane, etc. The established methods of dyeing such blends are extremely time consuming and cost-intensive. These methods require large amounts of water and chemicals, which also leads to higher effluent loads and hence increase effluent treatment costs.

Econtrol T-CA process for continuous dyeing of fabrics consisting of blends of mainly polyester fibre with cellulosic fibres, and with elastane, e.g. Lycra. It is a one-bath process where the dyes for the polyester, cellulosic and elastane portions of the fabric are padded in a single bath in an alkaline medium. As a single stage dyeing process, the Econtrol T-CA offers significant benefits both economically and ecologically. For successful Econtrol T-CA dyeing, it is necessary to use a Monforts Thermex range with an Econtrol set-up; Levafix, Remazol, and Dianix dyes; and Sera auxiliaries for perfect process stability.

Econtrol T-CA: Benefits

-

Single pad-on continuous dyeing process for polyester, cellulosic, elastane blends

-

No intermediate reduction clearing necessary

-

No additional pad steam process required

-

Suitable for almost all the blend ratios of polyester, cellulosic fibres and elastane

-

Possible to cover a wide range of shades with the dyes available

-

The simple lab process enables bulk reproducibility

-

Fulfils fashion fastness requirements

-

Offers significant cost savings compared to the standard PDTPS (pad-dry-thermosol-pad-steam) process.

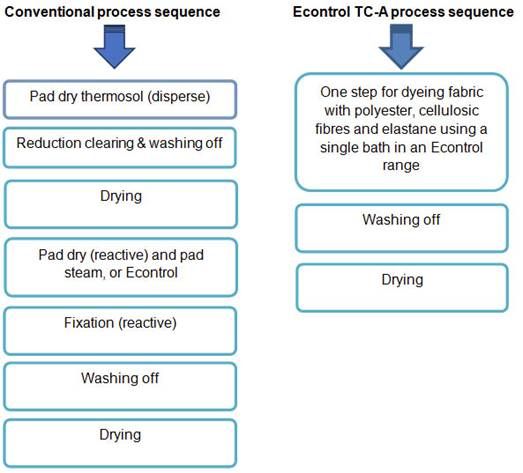

Process comparison

The conventional PDTPS process is a complex process consisting of many steps. The single bath Econtrol TC-A process is much easier to manage and ensures consistent results with lower cost of production compared to PDTPS process.

As the Econtrol T-CA process does not use separate baths or ranges for the polyester and cellulosic parts of the fabric, and reduction clearing is not necessary, this process saves large amounts of chemicals, water, and energy. It uses up to 80 per cent less chemicals, up to 60 per cent less water, and up to 50 per cent less energy.

Thus, the Econtrol T-CA process results in nearly 50 per cent reduction in production cost over the standard production processes.

Econtrol T-CA is therefore by all means the most advantageous process for process houses to meet the twin challenges of cost and the environment while dyeing blends of polyester, cellulosic fibres and elastane.

Comments