As a piece of technology gets more and more advanced, and often more complex, one of the biggest problems is repair. As Murphy’s Law states, anything that can go wrong will go wrong, ergo the more equipment there are that can be broken, the more time they will spend broken.

So, when a piece of equipment is both incredibly simple, functional and offers a seemingly complex solution to a commonplace problem, you are dealing with something very special. This is the case with self-healing cutting mats, and their apparently miraculous resistance to damage at the hands of conventional cutting tools.

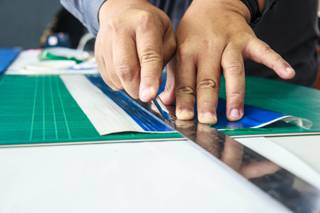

Cutting mats are available in a wide variety of styles and they provide a valuable service to the textiles industry. Not only do they prevent damage to the workplace itself, they have measurement units that can give a much-needed objective sense of scale and depth to the proceedings of design. By resisting sharp cutting blades, they ensure that surface worktops stay flat and stable.

Cutting mats are available in a wide variety of styles and they provide a valuable service to the textiles industry. Not only do they prevent damage to the workplace itself, they have measurement units that can give a much-needed objective sense of scale and depth to the proceedings of design. By resisting sharp cutting blades, they ensure that surface worktops stay flat and stable.

But while some mats will resist purely by the strength of the molecular bonds of the material, self-healing cutting mats go one step further. Indentations and cuts, while appearing normal and damaging at first, will gradually disappear as the material seems to re-take its original shape. This is no high-tech advancement or some form of organic residue technique.

Self-healing cutting mats work by using a type of rubber that undergoes a specific and very useful form of transformation when enough pressure is applied. Once the pressure crosses a certain point, the rubber expands back into the space that had been created by the cut. This happens because the internal structure of the rubber is constantly pressured to an extent. Thus, in much the same way that a vigorously shaken aluminium can of Coke will seek to fill the vacuum created when the purchaser pulls open the ring, so too will the inside of the rubber mat move to fill any vacuum created by the cut.

When the pressure returns to an equilibrium, the cut is seemingly sealed and the mat returns to its former glory. This brings with it many advantages that make them perfect for designers, artists and anyone who works hand-to-desk with cloth in the textiles industry.

Non-slip surface: With the pressurised nature of the rubber and its need to expand back into shape, this material makes a very grippy and stable surface for a wide variety of tasks.

No distractions: A huge amount of time can be lost when dealing with replacing tools or working around small-scale imperfections in equipment. The self-healing cutting mat means that time can be clawed back and made productive again.

Double-sided: The properties of the self-healing cutting mat are chemical, meaning they persist all the way through. This allows for multiple designs on either side, making the self-healing cutting mat doubly useful.

Long life: A self-healing cutting mat’s ability to repair its own damage means it can be used again for quite long, without having to worry about replacement or need to search for alternatives.

Although self-healing cutting mats are very advanced, these are far from invincible. Much in the same way that a Coke can will eventually go flat, a self-healing mat will lose much of the pressure in its rubber molecular bonds after a certain amount of time; far longer than most other types of mat, but not infinitely so. There are two main treatments for this and applying them will mean you can keep your mat stable and useful for longer.

Sanding: By sanding the mat down, you even out the relief of the cuts and intends that have been made over the years, allowing the damage to be more evenly spread and thus returning the mat to a more level form.

Clean heal: To make a mat even and return a damaged mat, possibly with fibres stuck into the cuts, back to health, immerse the mat in cool water, with 1/4 cup white vinegar per gallon of cool water, and leave it to soak for 15–20 mins. Once this is finished, use some common washing liquid to clean and brush away any loose fibres or other materials. This will return the mat to a supple, clean, fresh state, making it as level as possible. Dry it with a cotton towel or air dry it in the open, but make sure to leave it flat so it does not warp.

With these techniques, you can keep your mat useful and even surfaced for longer. Given how long a self-healing cutting mat can last already, applying these could mean you may never need to replace it again.

Comments