Thanks to the strong and stable production of combed cotton yarns, a new segment has opened up in China for the air-jet spinning machine J 26, as high-quality terry towels can be produced with this yarn, for example. That is not the only advantage, however.

For mills that want to produce air-jet cotton yarns, Rieter has the appropriate solution: the optimised spinning system and the technical and technological expertise. The mills benefit from low production costs and a quality of yarn significantly superior to that of competitors.

Cost and quality advantage in production

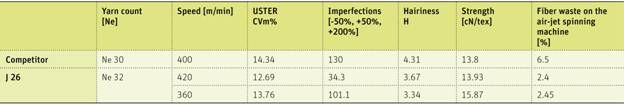

One of the largest Chinese mills carried out a comparison of the air-jet spinning machine J 26 with a competitor product over a period of six months. The J 26 convinced in a number of criteria.

Fig. 1 With slightly higher production, the Com4 jet yarn of the J 26 achieves better yarn values and lower fibre loss on the air-jet spinning machine.

The yarns spun on the J 26 at a higher production speed showed considerably better values for imperfections, evenness and strength (Fig. 1). The yarn hairiness was ideal for a soft touch with a low pilling tendency. The significantly lower fibre loss with the J 26 allows the mill an excellent raw material yield and this achieve annual cost savings of around 17 tons of cotton per air-jet spinning machine (basis of calculation: J 26 with 120 spinning units, yarn count Ne 32, delivery speed 420 m/min).

From the idea to the product

In China, a middle class with high purchasing power has emerged and that continues to grow. This lucrative consumer group is prepared to spend more money on high-quality products. Statistics confirm a strong growth in products in the higher price bracket.

Based on the properties of the Com4 jet yarn, the yarn of the J 26, an idea emerged of creating terry towels that meet the following criteria:

No pilling, even after a number of washing cycles

Brilliant colours throughout the entire lifetime

Quick absorption of moisture from the body

No fluffing, no loss of fibres during washing

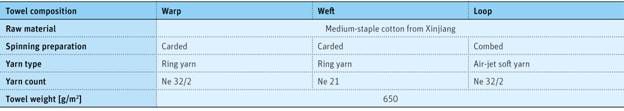

Fig. 2 The Rieter towel made from 100 per cent cotton was based on a fabric made from carded ring yarn and a loop made from combed air-jet yarn.

The Rieter Com4 jet yarn was used in the pile to produce the terry towels and combined with carded ring yarns in the ground warp and weft, also produced by the customer (Fig.2).

20 Rieter towels were given out to test persons to assess quality. Their feedback was univocal. Compared to the towels they currently used, they assessed the appearance and feel of the Com4 jet towels as 'excellent'. Water was absorbed quickly; the formation of lint and fluffing were minimal.

Fig. 3 Compared to the high-quality towel, the Rieter towel (right) made from Com4 jet yarn already performs extremely well visually.

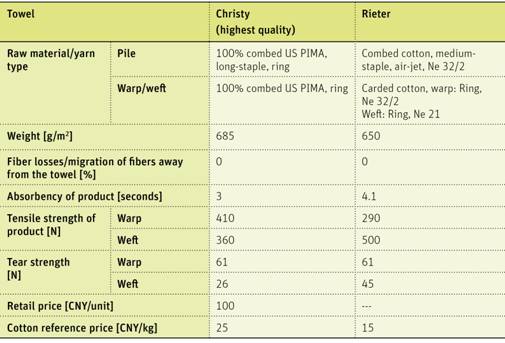

The independent Swiss test laboratory SGS was contacted for a neutral assessment. In addition to the Rieter towel, an extremely high-quality towel from the internationally renowned Christy brand was also provided to obtain reference data. From a purely visual perspective, both towels were comparable (Fig. 3).

Fig. 4 The data collected by the independent test laboratory SGS confirmed that Com4 jet yarns are perfect for high-quality towels.

The test results showed that the Rieter towel with air-jet cotton yarn in the pile performed very well (Fig. 4). No fibres were lost - in other words: there was no fluffing. The Rieter towel kept its volume for a long time, as the pile remained upright and also retained its softness. The tensile strength and therefore the wear resistance were also excellent. The absorbency was almost at the level of the reference product and therefore corresponded to a very high level within the standard. Particularly interesting were the raw material costs. The yarn of the Rieter towels was spun from medium-staple cotton. This saves around 40 per cent on raw material costs compared to the long-staple cotton used in the Christy towel.

This study has shown that the Rieter air-jet spinning technology produces cotton yarns of a very high quality. Used correctly, the air-jet yarns can play to their strengths. The results are very attractive end products. In addition, a mill saves considerable raw material costs.

The interest in air-jet cotton yarns is growing. An increasing number of spinning mills and downstream users are developing products and benefit from the modern J 26 air-jet spinning technology and its special yarn properties.

Comments