Indications of what the textiles-apparel-fashion industry would look like in the next decade would be seen at the week-long ITMA 2019 which gets under way later this month.

Every four years, the global textiles-apparel-fashion industry converges at ITMA. If there are a number of #mustattend events out there, this would be the mother of them all. It is an event that in many ways not only shapes the future of industry, but just living as well.

And as the ITMA Services, which is organising ITMA 2019 at Barcelona this month, says on its website: "ITMA is the trendsetting textile and garment technology platform where the industry converges every four years to explore fresh ideas, effective solutions and collaborative partnerships for business growth." Nothing could be more succinct. But still, this does not fully capture the import of the event-for many, this is almost like a four-yearly pilgrimage.

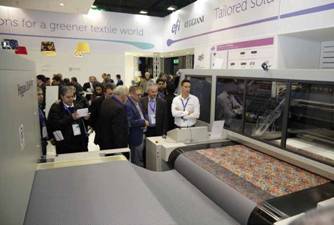

Yet, the zest, the exuberance and even that tinge of desperation of participants / visitors is in many ways reflected in the scale of the event: there would be 19 exhibit areas showcasing integrated solutions for the entire value chain; over 220,000 sq m of advanced technologies and live machinery demonstrations; 1,600 exhibitors who are original manufacturers, among others.

What close to 120,000 visitors would get to see can be summed up thus: the future of manufacturing. Crystal-gazing is what you do sitting in your home, or maybe office. At ITMA, you can see the future unfolding right in front of your eyes. You wouldn't want to be-well-sitting at home.

Much of what would be the future has a word for it today: innovation. ITMA 2019, therefore, sums it up with its catchline: innovating the world of textiles.

The Future Lies in Innovation

In an industry with such a long-winding value chain (ITMA 2019 would have as many as 19 exhibit areas for the chain), innovations would mean different things to different people. Yet, there would be some that would be key to the direction that industry takes. Could there be that one innovation that might be the disruptive force that industry might be looking for? If at all?

CEMATEX president, Fritz P Mayer believes, "Digitalisation promises to bring increased automation at all stages of the textile production chain, from the raw materials right to the consumer product, and to effect much better communication and interaction at every stage. At the same time, it will provide much greater transparency, traceability and ultimately accountability. So, sustainable claims will certainly have to be genuine going forward, or manufacturers can anticipate negative reactions.

"In the immediate term, it will become clear at ITMA 2019 that there are a number of waterless dyeing and finishing technologies that have the potential to be very disruptive when it comes to the overall footprint of textiles in terms of water, energy and raw material usage."

CEMATEX (Le Comite Europeen des Constructeurs de Machines Textiles) comprises nine national European textile machinery associations. It is also the owner of ITMA, the world's largest international textile machinery exhibition.

But, Therese Premler-Andersson, secretary-general of Textile Machinery Association of Sweden (TMAS) does not think there is one innovation that will be the key to progress in the industry. "It will rather be a combination of innovations and technologies that will make the difference. In the future, it will not be about doing things faster, but smarter. Using sensors, such as those from TMAS member Eltex, for monitoring yarn tension in real time, for example, illustrates how to increase the quality of the yarns coming from warp beams and minimises production down time.

"Automatic production and the robotic handling of goods are other areas where we have seen big developments over the past few years. Swedish companies such as Eton Systems and ACG Kinna Automatic are truly among the leaders within automation for garment and home textiles production. The realtime monitoring of data meanwhile opens up the opportunity for textile manufacturers to react instantly and optimise and fine-tune their production."

In fact, she outlines, "In combination with the integration of the value chain via new interfaces between process steps, this is providing a new flexibility and customisation within the textile and garment industry. Artificial intelligence and machine learning, the use of 3D scanning for the personalisation of clothing and the reuse of materials will also make a huge difference in the medium-term, but these are all very new concepts in the bigger scheme of things."

Professor Thomas Gries of the Institut fur Textiltechnik (ITA) at RWTH Aachen University thinks this is a very good time for innovation. "The textiles industry is once again in a period of upheaval. Global processes such as climate change, the growing world population and increasing prosperity in Asia will change the face of the textiles industry. This is why we will increasingly see innovations from the textiles industry in the coming years. I am thinking-in particular-of the dimensions of production, materials and business models. I see particular potential in the area of production.

"We will move away from classical mass production to production in so-called micro-factories. Here at the RWTH Aachen University, we have been researching this topic for years. The response from industry to our research shows us that we are on the right track. So far, we have built six micro-factories for various products. It is our goal to extend this number up to 12 in the next three years." Premler-Andersson adds, "Let's also not forget resource efficiency too, where efforts from TMAS companies are ongoing, and at ITMA 2019, Baldwin Jimek, for example, will show something very special-the new Texcoat G4 precision spray application system for fabric finishing which is going to make a big impact in terms of the water, energy and raw materials savings it can achieve."

Herein, blockchain, among other things, is being talked about as one of those elements that would change a lot about the way supply chains function and bringing about an element of transparency. But for an industry that is global, this would have to transcend borders. Is the world ready for that kind of transparency, or will this operate only in limited spheres and geographical contexts?

Mayer looks at the overall picture, "Organisations across a wide range of sectors are already experimenting with blockchain technology to establish trust networks, improve transparency, and reduce friction and costs. Blockchain technology is one of the key factors changing trends in the fashion industry today. It has begun transforming the supply chain through track and trace and inventory management. With the advent of technologies like 3D printing and artificial intelligence, we expect this trend in the apparel industry to accelerate."

Premler-Andersson agrees that Industry 4.0 and the potential of financial models like blockchain are now leading to an increasing transparency and traceability all along the supply chain and making it much easier to track products, their contents and how and where they are produced. "It's also the case that there has been a lot of greenwashing in the past, but now, if a company claims it is doing something it has to prove it, or the NGOs will start pointing the finger, which can be extremely damaging to a brand's reputation."

Premler-Andersson agrees that Industry 4.0 and the potential of financial models like blockchain are now leading to an increasing transparency and traceability all along the supply chain and making it much easier to track products, their contents and how and where they are produced. "It's also the case that there has been a lot of greenwashing in the past, but now, if a company claims it is doing something it has to prove it, or the NGOs will start pointing the finger, which can be extremely damaging to a brand's reputation."

According to her, the young are leading and setting the agenda and will steer the way change will happen. They will pressure the NGOs and legislators to enforce the way the supply chains operate. "At the same time, one of our TMAS member companies-ACG Gruppen-is led by 90-year-old Reimar Westerlind, who has this simple message: 'Everything now is about automation and digitisation. We have to be on that track or we will be lost-innovate or die.' So, the changes now occurring are across geographies, but also across generations."

Gries sees blockchain technology as an exciting construct. "In principle, the technology is very well suited for use in the management of global supply chains. However, I don't currently believe it will be widely used in industry. The necessary infrastructure for the reliable use of the technology is too complex and expensive.

In addition, the technology also fails due to user acceptance, the sharing of sensitive process data is still viewed critically, transparency is not desired by everyone, although it would often be helpful. We work with blockchain technology in our Cluster of Excellence in Aachen. We will see in which markets the application will prevail."

It's fair to say that the textile sector's overall image has been that of a 'sunset industry' and in all parts of the world many banks are restrictive with loans. So, says Premler-Andersson, at the moment, the biggest cost for textile manufacturers is no longer labour or raw materials, but capital and depreciation of equipment. "Right now, the model is that the customer just buys a machine. The future, however, may be increasingly that manufacturers pay for licences by use, or square metre, or kilogram of whatever is being produced, with the fees going directly to the finance company which has taken ownership of the machine. Finance companies need to be made more aware of these new transformational concepts. They already seem to really work in other fields."

As innovation goes circular

Most of the initiatives taken from the circularity point of view, though laudable, have not really spread like wildfire. Is it that there are too many initiatives, or is it because there is not a concerted platform/approach? Is there a need for a policy intervention at the global level?

Mayer feels, "Circularity should be embedded in the way we do business because of the inherent ROI (return on investment)-more efficient resource management and a resilient supply chain, while enhancing customer loyalty by providing an end-of-life commitment to reuse and decommission products, and converting waste into use. Having said this, circularity is a complex subject with many facets and stakeholder engagement and involvement. While it may take time for the concept of the circular economy to be realised globally, many industries, such as textiles and garment, are starting to work in the right direction. A key factor to success will be collaboration across the value chain, from brand and retailers to garment makers to yarn and fabric suppliers, from collectors to recyclers.

"At a global level, major international groups are already working on this. For example, the World Economic Forum (WEF) has collaborated with the Ellen MacArthur Foundation for a number of years to accelerate the circular economy transition through a CEO-led initiative that helps to scale business driven circular economy innovations."

Gries, however, does not consider these initiatives to be viable in this form for one simple reason: they do not offer direct added value to the customer. "Why should he pay more for a textiles product with an eco-label or made of recycled plastic? In the end, it's the design that decides first, then the fit, and then the wallet. Sustainability is a luxury problem for consumers. So that you don't misunderstand me: I think sustainability is one of the most important issues of our time, but most people make their purchasing decisions emotionally and not rationally. Sustainability is a rational problem, and politics has a duty here. There must and will be increasing regulations in the future to further improve sustainability in industry. Industry must prepare itself for this step."

Given this backdrop, where can the maximum scope (and maybe, need too) for innovations lie in terms of sustainability? From growing of cotton and other natural fibres to processing to even garmenting and retailing, we are seeing innumerable measures being taken and innovations being done (particularly in terms of technology). Would we see a paradigm shift in terms of sustainable innovation(s) that can change the way the textiles and apparel industry itself functions?

Gries does not think we have reached the end of innovation yet. "As I have already said, there is a noticeable change in thinking in industry. The aim must be to massively reduce the CO2 footprint of industry and to increase the circularity of fibres. Further technological developments will come into the market in the coming years and further change the face of industry. In fact, I see a great chance in the application of AI (artificial intelligence). AI has gained new importance against the backdrop of digitisation to deal with the large amount of data available now.

"It is a most useful tool. The application areas of AI are to be found mainly in the areas of process automation, customer information analysis, digital image processing and also in the area of assistance systems (Work 4.0). In part, these methods have already been investigated and successfully validated in research and also in industrial projects. An industrial deployment on a broad basis is usually still pending."

As Mayer points out, "We have seen a positive change in the way the textiles and garment industry functions at various levels. Due to consumer demands, brands and manufacturers are introducing sustainable materials and processes within the supply chain. The textiles and garment industry is working towards driving longterm sustainability. The supply chain is more transparent as accountability falls on every member of the chain. There are now more certifications in the apparel industry to help companies ensure their products are meeting critical environmental standards."

As Mayer points out, "We have seen a positive change in the way the textiles and garment industry functions at various levels. Due to consumer demands, brands and manufacturers are introducing sustainable materials and processes within the supply chain. The textiles and garment industry is working towards driving longterm sustainability. The supply chain is more transparent as accountability falls on every member of the chain. There are now more certifications in the apparel industry to help companies ensure their products are meeting critical environmental standards."

In the scheme of things, everyone would have his/her own role to play. Yet, as Premler-Andersson contends, "Everyone within the value chain needs to play their part, but at the end of the day, the ultimate responsibility has to be with the brands. They have all the influence over the supply chain, and at the same time, are consumer-facing. I've heard it suggested, for instance, that brands should go as far as buying their own fibres and their own processing technologies right from the start. And why not? Maybe this seems extreme, but it's a logical argument for ultimately increasing transparency and traceability. Why shouldn't brands take responsibility for the cotton fields on which their cotton is grown?

"The Swedish textile machinery manufacturers have been working with increasing efficiency and reduced energy consumption for decades, as well as introducing initiatives to constantly reduce waste and to increase quality. The change that we see coming now is the awareness and interest from consumers about their textiles. That, in combination with new technology, is a strong force to make further improvements thought the value chain."

Research into the future

There is also the scope for more concerted efforts. Shouldn't industry associations at the global level come together to push the agendas of sustainability and transparency?

Points out Mayer, "There are already many industry associations working together to further the agenda of sustainability and transparency. At ITMA, we have been emphasising this message through our exhibition themes. In addition, we created the ITMA Sustainable Innovation Award which recognises the efforts of our exhibitors collaborating with their customers to introduce sustainable manufacturing solutions.

"We also welcome collaboration among various groups, and are inclusive by inviting perspectives from around the world. For the upcoming edition, we have the ITMA Textile Colourant & Chemical Leaders Forum. It's an industry forum organised by the industry, for the industry. The programme committee comprises representatives of colourant and chemical associations from around the world. We have also invited organisers of events pushing the green agenda to co-locate their events at ITMA 2019. These include the SAC & ZDHC Manufacturer Forum, Better Cotton Initiative Forum and Planet Textiles."

"We also welcome collaboration among various groups, and are inclusive by inviting perspectives from around the world. For the upcoming edition, we have the ITMA Textile Colourant & Chemical Leaders Forum. It's an industry forum organised by the industry, for the industry. The programme committee comprises representatives of colourant and chemical associations from around the world. We have also invited organisers of events pushing the green agenda to co-locate their events at ITMA 2019. These include the SAC & ZDHC Manufacturer Forum, Better Cotton Initiative Forum and Planet Textiles."

Adds Premler-Andersson, "We come together as much as is probably possible. The national industry associations bring the textile machinery manufacturers together, as well as linking them with research institutes, universities, manufacturers and brands. The joint development of technologies and supply chain cooperation has intensified considerably in recent years. The European associations are meanwhile united under CEMATEX, of course, for the promotion of ITMA exhibitions and many other activities, and are in close contact with their counterparts around the world, for the corresponding ITMA Asia shows, and other events and campaigns."

The innovation awards at ITMA, as mentioned by Mayer, do create a buzz. There are, and have been, scores of awards that are given away for innovations. Similarly, every month sees some new development or the other in terms of fibres or technology. But most of these hardly ever make it out of the lab and many never even see mass production. That would beg the question: shouldn't R&D initiatives need to keep feasibility / implementation more in mind?

Says Mayer: "Recent estimates by the United Nations put global spending on research and development at $1.7 trillion a year. This is an enormous sum spent by researchers trying to innovate everything from new products to sustainability enhancements. Innovating for the sake of innovation is not practical for a commercial organisation. R&D should always have a purpose, one that serves the needs and goals of the organisation while solving challenges or the needs of the world. Companies must develop a deep understanding of customer needs; the ability to create products that serve genuine customer needs is the foundation for successful innovation."

Premler-Andersson believes all research of good quality is positive and will contribute to a better society in the long run. "We need to always encourage curiosity and experimentation. That said, it's clear that it sometimes takes a long time before it becomes apparent what benefit research leads to, or what good it can do for the industry. Even if it comes to nothing, the exploration of new ideas is always positive. Often, it is not the big scientific breakthroughs that have the biggest effects, but small, systematic tests and research that build on the breakthroughs. We need structural interaction between business-driven development projects and experimental research institutes. We are working on this constantly at TMAS."

Gries, however, feels there is indeed a great need for improvement here. "There are great ideas and approaches in industry, but also in research. There must be a better exchange between research and industry. Here in Aachen, we are already working very closely with industry. But we would also be pleased to further expand the cooperation. Cooperation is most productive when we can discuss concrete problems with industry. In a research environment like our institute, you can try things out and keep the effort to a minimum. Ideas are developed iteratively and uncomplicatedly, so that the potential becomes visible more quickly. Here at ITA we have a strong team of experienced and young, creative scientists. This team is the basis for our successful industrial research."

Comments