Pradeep Kulshrestha explains the benefits of direct creel in weaving.

Conventional weaving was carried out by warp packages, beginning with warping-direct and sectional, then sizing, if required, and then on looms. But the process now has been modified, especially in technical textiles. It is simple and cost effective. Due to continuity of longer warp length through drum in running loom, loss of time in beam gaiting is fully avoided. Less contribution of skilled manpower also reduces the weaving cost with satisfactory production and product quality.

The floor space depends on sorts to run on loom. Provisions for more than one type of warp packages to hold yarn or fibre can be made. This is very effective in saving costs and maintaining consistency in woven fabric productivity if the same product is running for longer time.

Conventional warping process: For weaving, warp ends earlier came from direct creel or V-creel to wind on wrappers beam in direct warping and on weavers beam in sectional warping. These beams require beam gaiting on loom. Warping needed minimum one operator and a helper; beam gaiting required minimum three-beam gaiter, assistant and fitter. Six to eight looms were allocated to a team of weaver and helper. These seven skilled workers can now be replaced by a weaver and one or two helpers on loom if direct creel and drum weaving is carried out.

Waste control: Due to continuity in weaving, much lesser quantity of warp waste is generated compared to weaving with weavers beam. In rapier looms, selvedge waste remains under norm (less than 3 per cent).

Saving in time: Beam gaiting is not required, and therefore, a lot of time is saved, as there is no need to frequently reset loom and troubleshoot to repeatedly produce fabric without defects as per sample. Exhausted warp packages can be replaced during weaving by just applying knots at both ends.

Scheduled maintenance: For exclusive cleaning and lubrication of loom, total packages on creel need to be changed, or else the warp packages can be changed intermittently without affecting loom functioning.

Safety of creel:

Creel is balanced by its own weight and the total weight of warp material kept on it. It is advisable to put foundation bolts as well as support from wall and pillars so that it may not fall down or vibrate with working loom. Even detachable racks should be joined together and can be separated, if required.

Creel is balanced by its own weight and the total weight of warp material kept on it. It is advisable to put foundation bolts as well as support from wall and pillars so that it may not fall down or vibrate with working loom. Even detachable racks should be joined together and can be separated, if required.

Possibility of high efficiency:

In fact the opportunity of process control during weaving is more in direct creel because an individual package can be replaced if it causes difficulty during weaving, but in beam, nothing can be done except compromising quality. Efficiency is not affected because of more beam preparation defects to rectify on loom or to compromise with loom working till beam finish.

In fact the opportunity of process control during weaving is more in direct creel because an individual package can be replaced if it causes difficulty during weaving, but in beam, nothing can be done except compromising quality. Efficiency is not affected because of more beam preparation defects to rectify on loom or to compromise with loom working till beam finish.

Many fabricators in India are making direct weaving creel at low investment to convert rapier and projectile weaving looms from 'beam to creel facility'.

Replacement of weavers beam can be carried out by revolving the metallic drum.

Fabricators are making creel for sectional warpers, direct warpers and beaming machines based on yarn or roving package type to be used. Different tensioners are available for each application-from finest polyester monofilament to coarse carbon fibre.

Cost savings in fibre: If weaving of small-length fibre is required for composite research and applications, during initial rewinding from big warp package to small packages and at completion, pre-estimated other yarn of cheaper cost can be tied that will be wasted in process.

Weaving options: For running Dyneema, various provisions using aramid, carbon, polypropylene, glass, etc are made to adjust the warp layer upon the drum. Even the same loom may be operated by creel-drum method or putting weavers beam on its bracket. For a range of weaving yarns, this provision is optional. In modern looms, drum and creel are not deteriorated through long term usage if scheduled maintenance and lubrication is conducted properly.

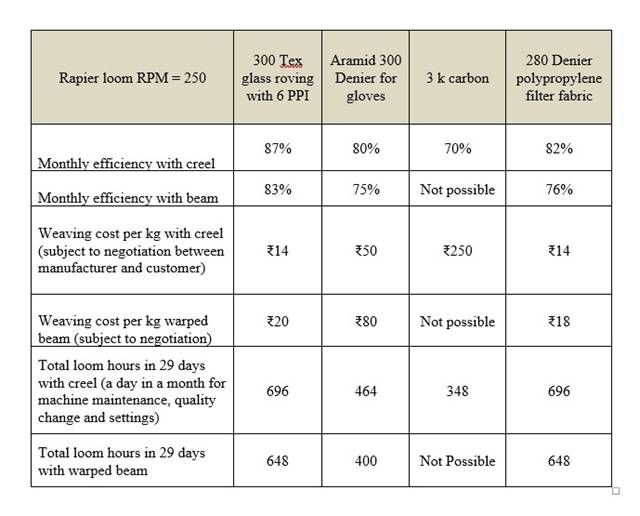

Comparison of direct creel loom and loom working with beam:

Conclusion: For continuous requirements of fabrics like carbon, aramid, glass, etc, direct creel is an appropriate process with loom for mass production. Even small quantity of costly fabric can be woven by rewinding the required number of warp packages from a few big packages. Power consumption is minimum because a number of equipment are limited with direct creel weaving technology.

Furthermore, the versatility of the loom is an important factor, so that most fabrics can be woven as per changing requirements and trends. Looms are mostly equipped with microprocessor-based controls. Analysing their data and taking timely action will result in optimum productivity. Direct creel have many provisions to fit spool, direct package, open end package and ring packages and tension can be regulated accordingly.

Comments