It’s the virus attack and it is only getting bigger. Here’s a rough guide for apparel manufacturers on how to deal with it, with special focus on addressing health concerns and supporting the workforce.

We are in the middle of a global crisis. Humanity is facing what can be called an international emergency, probably worst in modern history, in the form of the covid-19 pandemic. It has caught people by a cruel surprise and worst fears of this catastrophe impacting the world are looming large in front of us. The spread is global and almost all countries are impacted and fighting the disease.

There are challenges for many to make it through the crisis and to survive. It is too early to comprehend the economic impact of this crisis which has hit hard the global structures.

Garment industry happens to be one of the worst sufferers. Global fashion brands and retailers have pulled the shutters down in their major consumption markets of the US and Europe. Many are reported to have suspended the deliveries of ready merchandise parked at the ports waiting to be shipped and in the factories across the world. Majority of this supplier base is the factories in Asia.

There is no doubt that this would have a devastating effect on millions of garment workers and businesses that work on thin margins. As per BGMEA (Bangladesh Garment Manufacturers and Exporters Association) estimates, till April 2, shipments worth $2.96 billion have already been cancelled or suspended, involving 1,085 factories and 2.15 million workers. In India, the factories in Target have confirmed that they will receive the orders already produced and under the production. Tiruppur have been shut since March 22 onwards. The factory owners have promised to pay full salary to workers. Rest of the factories in India have also been shut with the national lockdown from March 25. Industry in Myanmar has already seen some factory closures and it is not much different for other apparel manufacturing nations like Vietnam, Cambodia, Sri Lanka and others.

It is true that we are all in it together and everybody is suffering or will suffer. This involves brands, retailers, importers, sourcing companies, apparel manufactures, sub-contractors and most importantly, the workers. However, we must realise that the capacity to cope with disaster is not same for all. If we can work together and help each other, the pain of this pandemic can be minimised. Brands who have benefitted low cost imports from supplier countries need to play their role to support their partners. As it is said, “Pain when shared reduces and joy when shared multiplies.”

The Indian minister for textiles Smriti Irani has made an appeal the global apparel buyers not to cancel the shipments. She has said, “Let us show the world that we can do commerce with compassion.” BGMEA president Rubana Huq has also made a spirited appeal to buyers not to abandon Bangladesh industry in this hour of disaster. It is time to listen to one’s heart and act in a compassionate manner. These appeals received a lot of media attention across the globe and seem to have made some difference. By March 31, as per news reports six retailors including H&M, Inditex, M&S, Kiabi, PVH and Target have confirmed that they will receive the orders already produced and under the production.

As the appeals to the international buyers have started showing some results and pressure is mounting on others to act, I would like to focus on what can the industry do with special focus on addressing the health concerns and supporting workforce.

On the humanitarian response side, we have several initiatives taken by the fashion industry like:

• Retailers like H&M, C&A, GAP and others are offering their supply chains to procure and supply PPEs;

• Brandix in Sri Lanka and Ikea in India offered their facility as a quarantine centre to support health infrastructure;

• Reliance has set up a dedicated coronavirus hospital in Mumbai;

• Leading Indian designer Anita Dongre created a fund for protecting artisans and small vendors. International designers like Armani, Versace and many more are making donations to support affected people;

• Designers and innovators are coming out with low cost and rapidly producible PPEs and more initiatives.

All these efforts need to be lauded and thousands more are needed globally as the challenge is enormous.

I am sharing some of my thoughts that the members of the apparel manufacturing industry may find worth considering. These are presented separately for the apparel manufacturers that are still operating factories depending on their country, risk perception/ government advise and the manufacturers that have already closed the factories as a precautionary measure.

What can the factories that are still working do?

-

Follow the advisory on social distancing forthe workforce (physical distancing is a better term).

-

Use the factory communication channels toimprove the awareness among the workforce about theprecautions to be taken at work, while travelling to factory, and at communityor home. This will not only help our workers, but the community as a whole.

-

You could produce masks and or protectiveclothing. Follow the specifications of WHO. The guidelines of AAMIfor hospital gowns could be useful or look for your National Standards. Thiswould be a great contribution towards protecting the frontline healthprofessionals fighting the battle against the corona pandemic. There areseveral buyers looking for these. Already several garment factories and socialenterprises have started working on this.

-

Use the time for training the workforce: Ifyou are not able to run all the lines full time due to material shortage,please use the time available to train the workforce on various topics that youdid not find time to do earlier.

- Prepare the workforce for the eventual lockdown. They would greatly benefit if your trainers and managers can guide them on how to lead their life during the lockdown or travel restrictions. People travelling to home towns or villages in large numbers can be very dangerous.

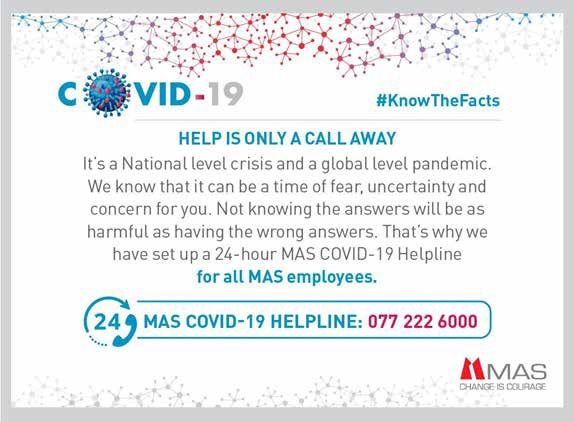

- Create a helpline for your employees. This will help them reach out anytime if they need help. Several companies have taken such actions. For example, see the poster from MAS Holdings, Sri Lanka.

What can the factories do that are currently closed?

-

Please create Whatsapp groups, ifyou do not already have, to disseminate health related authentic advisory toyour workforce in local language. Remember that there are a lot of rumours /myths going around. Create smaller groups with anchor persons connected tocoordinators to manage the logistics.

-

Motivate them to follow the instructions of government / health authorities. Peoplemay act impulsively and put their own and others’ lives in danger.

-

Provide emotional support: Your workforce would be under severe distress and may not be equipped to handle thesituation emotionally. Provide emotional support on how to manage themselves.Your HR team may be able to help or look for good external source.

-

Have help lines active sothat your people in distress can reach out and receive advise. Share examplesand stories of positivity to lift the morale.

-

Guide on how to manage financial stress? There would be severe financial stress.Share simple to apply tips about do’s and don’ts so that your workforce cannavigate through the financial crisis as much as possible.

- Start long-distance training sessions on soft skills or any other topics through platforms like Zoom, Google Hangout or Skype.

I hope some of these thoughts are useful to you. I shall be pleased to hear your thoughts on how you think the industry can contribute further. One thing is certain, if we join our hands with a resolve, we can reduce a lot of suffering and bring smiles on a few faces in this hour of crisis. Let us work together to support the most vulnerable and most valuable players of our supply chains, the garment workers!

Comments