R G Panneerselvam, K Gowri and M Anandan analyse the difference between the steps involved in producing patterned carpet chenille pile yarn and patterned velvet chenille pile yarn

Figured velvet chenille pile fabric (FVCPF) is a unique pile fabric having similar figure effect of coloured weft tufts on both sides woven with colour patterned velvet chenille pile yarn by following distinctive designing and weaving techniques using two handlooms.

The first handloom is set and all the required patterned weft fabrics are woven as per the calculated colour pattern. The second handloom is used to produce final fabric by weaving or setting the patterned velvet chenille pile yarn as per the targeted motif. The different quality parameters-weft tufts per cm, diameter and crimp of velvet chenille pile yarn, weft tufts per sqcm and weight and thickness of the figured velvet chenille pile fabric-have been summarised. The advantages of producing traditional FVCPF over figured carpet chenille pile fabric were studied. It was found that the existing decentralised power loom and handloom clusters together can very well take the production of FVCPF to manufacture diversified products like carpets, table mats, door mats and bathroom mats not only for the domestic markets but also for exports.

History

The traditional handloom weavers in the regions of Bhadohi-Mirzapur, Panipat, Jaipur and Agra have been well known for weaving different pile carpet/rug fabrics dating back to the 16th century. It is believed that weaving in these regions was established centuries ago by Iranian master weavers while travelling to India.1 The carpet types include cotton dhurry, Chhapra Mir carpets, Loribaft, Indo Gabbeh and Nepalese carpets and chenille rugs. 'Chenille' refers to either a type of yarn or fabric made from it. Chenille is the French word for caterpillar whose fur, the yarn is supposed to resemble. According to textile historians, chenille-type yarn is a recent invention, dating to the 18th century and believed to have been originated in France in the 1780s.2 The original technique involved was weaving a 'leno' fabric and then cutting the fabric into strips to make the chenille yarn. Alexander Buchanan, a foreman in a Paisley fabric mill, is credited with introducing chenille fabric to Scotland in the 1830s. There, he developed a way to weave fuzzy shawls. Tufts of coloured wool were woven together into a blanket that was then cut into strips. They were treated by heating rollers to create the frizz. This resulted in a very soft, fuzzy fabric named chenille.3

Chenille voile was also described as fabric embellished with designs that are usually developed by means of stripes of velvet or plush weft pile.4 Chenille yarn consists of short length of spun yarns or filaments that are held together by two or four ends of highly twisted fine strong yarns. The short lengths are called pile or tuft and the highly twisted yarns are called core or lock yarn.

Chenille yarn count is determined by lock yarn count, tuft yarn count and the amount of tuft yarn fed onto the lock yarn.5 Three operations are required in producing chenille pile fabric using chenille pile yarn. The first operation is weft fabric weaving, the second

Chenille yarn count is determined by lock yarn count, tuft yarn count and the amount of tuft yarn fed onto the lock yarn.5 Three operations are required in producing chenille pile fabric using chenille pile yarn. The first operation is weft fabric weaving, the second operation is chenille pile yarn preparing and the third is chenille pile yarn setting/weaving.6

The distinctive feature of chenille pile figured fabric generated by using chenille yarn is a plain weave cut piled fabric produced without the aid of wires and it shows the same figure effects of coloured weft tufts on both sides unlike those fabrics woven on jacquard loom.7

Figured velvet chenille pile fabric

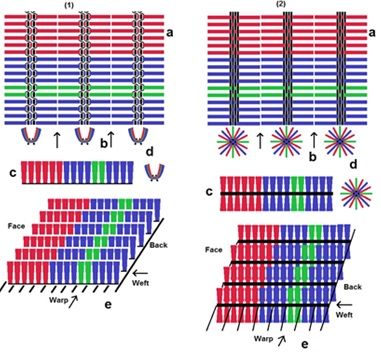

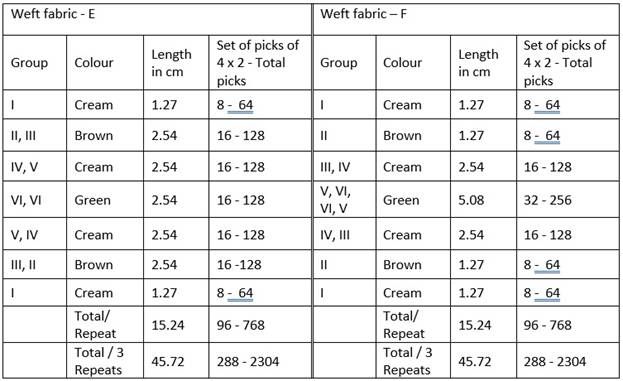

There are two types of chenille pile yarn: carpet chenille pile yarn (CCPY) and velvet chenille pile yarn (VCPY). For producing CCPY, the first process of weft fabric weaving operation is carried in the first loom. The weft fabric is produced by interweaving the weft yarn with groups of warp threads in 'leno weave' that are placed some distance apart as shown in Fig. 1a.

This is followed by the second process of preparing V-shaped chenille pile yarn, in which the weft fabric is first converted into a number of long strips by cutting in the middle as shown in Fig. 1b and 1c. In the subsequent operation, by following heat, moisture and pressure-setting processes, the weft tufts project from the gauze warp threads at one direction assuming a V shape and that is called CCPY as shown in Fig 1d.

In the third process of chenille yarn setting, the V-shaped CCPY is woven in the second loom using special weaves, making the tufts to project from the foundation cloth to produce simple carpet chenille pile fabric (SCCPF). The carpet chenille pile fabric thus produced becomes non-reversible because of the V-shape CCPY as shown in Fig 1d.

For producing VCPY, the first process of weft fabric weaving operation is carried in the first loom. The weft fabric is produced by interweaving the weft yarn with groups of warp threads in plain weave (leno weave in CCPY) that are placed some distance apart as shown in Fig 2a. This is followed by the second process of preparing round-shaped chenille pile yarn in which the weft fabric is first converted into a number of long strips by cutting in the middle as shown in Fig 2b and 2c.

By subsequent twisting process (heat setting in CCPY) the weft tufts project from the plain warp threads in all directions assuming round shape (V shape in CCPY) which is called as 'Velvet Chenille Pile Yarn (VCPY)' as shown in Fig 2d. In the third process of chenille pile yarn setting, the round shape VCPY is woven in the second loom using 'plain weave' (special weave in CCPY) with warp set in low dense and to be covered completely by the VCPY to produce 'Simple Velvet Chenille Pile Fabric (SVCPF)'. The velvet chenille pile fabric thus produced becomes reversible because of round shape VCPY as shown in Fig 2d.

Fig. 1 – Carpet Chenille pile yarn and fabric and Fig. 2 – Velvet Chenille pile yarn and fabric

Designing plays a vital role in producing 'Figured Chenille Pile Fabric' of these two varieties, that is, 'Figured Carpet Chenille Pile Fabric (FCCPF)' and 'Figured Velvet Chenille Pile Fabric (FVCPF)' using CCPY and VCPY respectively. In producing both the varieties of figured chenille fabric, first of all, a targeted motif is decided and its colour pattern is designed. In the second process, the weft yarn of different colours is woven to produce fabric in a definite weft pattern as per the colour pattern of targeted motif. In the third process, the patterned chenille pile yarn is prepared from the weft patterned fabric. The patterned colour tufts in the chenille pile yarn is set to produce targeted motif in the fourth process of chenille pile yarn setting/ weaving. Hence, in producing figured chenille pile fabric of both the varieties, the processes to be followed are 'motif and pattern designing', 'patterned weft fabric weaving', 'patterned chenille pile yarn preparing' and 'figured chenille pile fabric weaving'.

From the Fig 1 and Fig 2, the colour pattern of chenille yarn horizontally seen in the final fabric is 6 red, 4 blue, 2 green and 4 blue and it represents width of each colour required. It is to observe that the horizontal pattern in the final fabric is vertically seen in the weft patterned fabric woven in the first loom. This means that the figured colour deign required in the final fabric has to be rotated 90O and has to be read horizontally for colour patterning

This study discusses about the second type; FPCVF using round-shape patterned velvet chenille pile yarn. An experiment was conducted to produce a small table mat of FPCVF by taking a simple motif. Different weft fabrics to be woven and weft colour pattern of each fabric were derived from the motif. Two looms were set, one to weave patterned weft fabric and other to weave chenille pile yarn weaving. The designing and weaving particulars were noted along with photographs. The quality particulars of patterned VCPY produced and the FVCPF woven were recorded.

The uniqueness of FVCPF is its reversible usage with same figure on both sides, smoothness due to weft yarn tufts and thickness. Because of these features, figured velvet chenille pile weaving can be used to manufacture diversified products like carpets, table mats, door mats and bathroom mats of high quality. For this, it is highly essential to train the young weavers to practice and make them confident to produce FVCPF. It is necessary to train a designer and a set of three persons to weave the fabric. The designer has to handle designing and calculations of colour patterning. The first weaver to weave in first loom to produce weft colour patterned fabric. The second one helps cut the fabric into strips and twist it to produce patterned velvet chenille pile yarn. The third one is the weaver who weaves the patterned velvet chenille pile yarn into fabric by properly placing the patterned yarn similar to weft tie and dye fabric weaving. This study aims to record the designing and weaving techniques involved in systematically producing this pile fabric to make the present generation of textile technologists understand the strength of the handloom technology and transfer the same to the weavers.

Motif and pattern designing

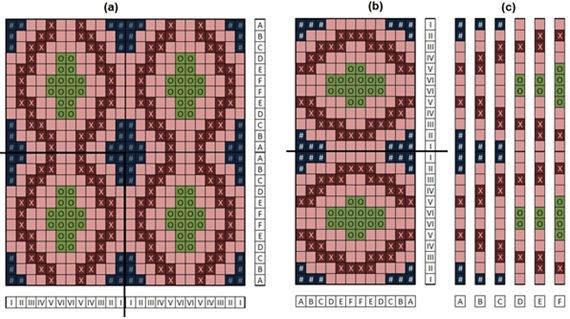

A simple repeat of multi symmetrical geometrical motif is prepared in 12 x 12 graph in three colours indicated by three different marks (X, O, #) with ground left as blank. The repeat is shown at the bottom left of Fig 3(a). Blank ground corresponds to cream colour. 'X', 'O' and '#' marks indicate brown, green and black colours respectively. Four repeats of this motif arranged in 2 repeats x 2 repeats, as shown in Fig 3(a), which indicates the final figured velvet chenille pile table mat of 30.48 cm x 30.48 cm (12" x 12") in size to be woven in second loom. Therefore, each square in the motif is considered equal to 1.27 sq cm (0.5 sq inch) and the repeat becomes 15.24 sq cm. (6 sq inch). Each vertical space in the motif corresponds to 1.27 cm (0.5") width of chenille pile yarn in the final fabric and each horizontal space corresponds to 1.27 cm (0.5") length of final fabric woven by chenille pile yarn. The twelve vertical spaces of repeat of motif, which are bisymmetrical of six different vertical spaces, are numbered serially from 'I to VI' and then 'VI to I'. Similarly the twelve horizontal spaces that are bisymmetrical of six different horizontal spaces, are numbered serially from 'A to F' and then from 'F to A'.

Fig. 3 - (a) Repeat of geometrical motif in 12 X 12 and four repeats of motif representing final table mat, (b) Motif is turned 90O and (c) six weft colour patterns (A to F) are derived for weaving weft fabric

The 12 X 12 design in Fig 3(a) is turned 90o as seen in Fig. 3(b), by which the horizontal spaces become vertical and vice versa. In the turned design in Fig 3(b), each vertical space from A to F represents warp threads and each horizontal spaces 'I to VI' represents weft threads of patterned weft fabric to be woven in the first loom. In Fig 3(c) six different vertical spaces, A to F, are indicated separately to understand the repeating of weft pattern. This shows that during the first process of weft fabric weaving in the first loom, six different weft fabrics 'A to F' of sufficient length are required to be produced in which the colour weft is woven as per the sequence of colour pattern /marks in the horizontal spaces.

Weft patterned weft fabric weaving

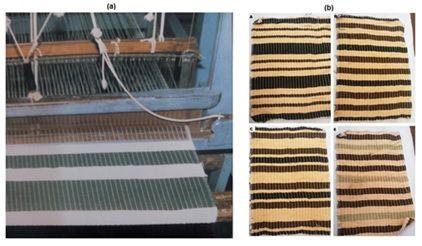

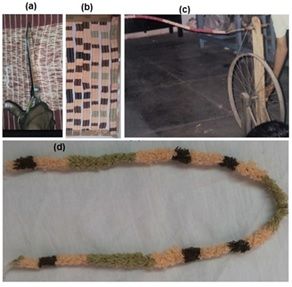

The first handloom is set with two healds and two treadles, as shown in Fig 4(a), for the first process of weft patterned weft fabric weaving in plain weave as per the calculated weft colour pattern. Warp count of 60/2 tex in white colour is drawn in the two healds. The reed contains 24 splits in 2.54 cm. Four ends are drawn in a dent making a set of core or lock yarn. Eleven splits are left empty between each set, which makes 1.27 cm space left between each set of 4 ends. Total width of warp is set to contain 65 sets of four ends. Apart from this, selvedge of 1.27 cm width on each side is set with 2 ply of warp yarn by leaving 11 splits space. Thus, the total width of warp becomes 86.6 cm [1.27 cm (66 spaces x1.27 cm) 1.27 cm]. The total ends in the warp are 356 [48 (65x4) 48].

Fig. 4 - (a) First loom set to weave weft patterned weft fabric and (b) Weft patterned weft fabrics A, B, C and E woven from first loom

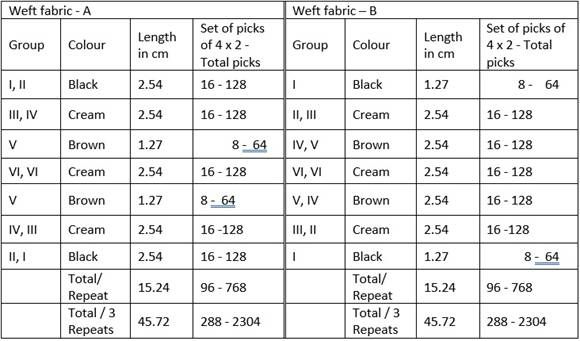

The weft yarn count of 60 Tex is used in 2 ply resulting in 120 Tex. Four picks of 2 ply weft is woven in each shed using 'catch cord system' that is taken as a set. Initially by trial, it is noted that with normal beating, 8 sets of 4 picks of 2 ply weft yarn occupies 1.27 cm length of fabric on loom. That is, in total, 64 picks (8 x 4 x 2) are woven in 1.27 cm on loom which is equal to size of each horizontal space taken in designing the motif. With this, the colour pattern to be followed for each weft fabric is calculated in terms of number of sets of eight picks as given in Table 1, 2 and 3.

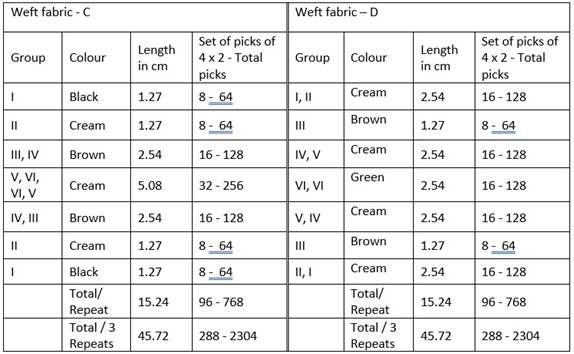

Table: Weft colour pattern of weft fabric A and B

Table 2: Weft colour pattern of weft fabric C and D

Table 3: Weft colour pattern of weft fabric E and F

Each weft fabric is woven by repeating the colour pattern thrice. Since, each repeat of pattern is 15.24 cm, the length of fabric produced in each pattern is 45.72 cm on loom. While weaving each fabric, extra picks are woven for one centimetre and 4 to 5 cm length of warp threads are left at starting and ending which facilitate for the next process of velvet chenille yarn preparation. Thus six weft patterned weft fabrics 'A to F' are made ready for the next process, out of which four fabrics A, B, C and E are shown in Fig 4(b). The fabric woven contain warp threads as white vertical lines at distance apart and completely packed with weft in different cross over colour effects. Hence, the fabric is termed weft patterned weft fabric.

Patterned velvet chenille yarn preparing

The next process consists of cutting the picks of weft patterned weft fabric woven in the first loom to form lengthy strips. The picks are cut in the centre of the space between the gaps formed by the group of plain ends as seen Fig 5(a). All the six fabrics woven in the first loom are cut into strips and are serially arranged as shown in Fig. 5(b). As there are 65 sets of plain ends, 65 strips are obtained from each weft fabric having similar colour pattern. Each strip is twisted by using hand operated charkha. The excess length of four warp threads available at one side of each strip helps fasten the strip with the spindle of the charka and the length available on the other side helps to hold the strip while twisting which is seen in Fig. 5(c). By twisting sufficiently, the strip completely gets twisted resulting to form 'round shape velvet chenille pile yarn' as seen in Fig 5(d), which is prepared from weft strip F. By trial, it is found that on an average, 36 turns makes the 45.72 cm length of strip to form a round shape by completely spreading the weft tufts in all 360O of four core ends in the centre.

Fig. 5 – (a) Weft fabric cutting into strips, (b) weft strips A to F, (c) twisting of strip and (d) patterned velvet chenille yarn prepared from weft strip F

All the six sets of 65 strips are twisted and converted to patterned velvet chenille pile yarn with six different colour patterns precisely arranged according to the pre-determined design. Six sets are serially numbered from A to F.

It is calculated that the length of weft fabric (length of each strip) which was 45.72 cm on loom, become 43.82 cm length on the table (excluding the extra length of core yarn and extra weft woven on both the edges). After twisting the strip, the length of chenille yarn is 41.91 cm. That means each repeat of weft colour pattern that was 15.24 on loom, become 13.97 cm in chenille yarn. Hence, the number of weft tufts that was 64 per 1.27 cm on loom also proportionately becomes 70 per 1.27 cm in chenille yarn, which is equal to 55 tufts per one cm. It is also calculated that after cutting the weft fabric into strips on table, width of each strip is 1.13 cm, which was 1.27 cm width on loom (equal to space left between each set of four core ends). After twisting, the width of strip that is diameter of chenille yarn becomes 0.95 cm.

Chenille pile yarn weaving

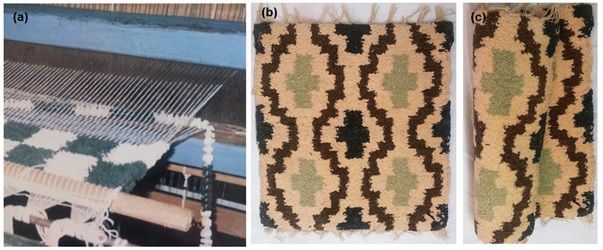

In the final fourth process of fabric weaving, the chenille pile yarn prepared in the third process is woven as weft in the second loom set with warp threads. A handloom is set to weave plain weave with two healds and two treadles as seen in Fig 6(a). Warp count is 120/2 Tex in white colour and reed contains 8 splits in 2.54 cm. One end is drawn in a dent resulting 8 ends in 2.54 cm. Width of warp is set to 28 cm by having 88 ends in total. This is because, one repeat of colour pattern in the chenille yarn is in 14 cm and it is decided to have two repeats in the width way. It is also to note that while designing, the width of 2 repeats was assumed to be 30.48 cm but the width of actual fabric is only 28 cm.

Fig. 6 – (a) Second loom set to weave final fabric, (b) final figured velvet chenille pile table mat woven same as motif in Fig. 3 and (c) reverse side of fabric similar to that of face side

Weaving is started with the first set of chenille yarn prepared from weft fabric A. The excess length of core ends along with extra tuft piles on both the edges of each chenille yarn are cut and removed just before inserting the chenille yarn in the plain shed formed. The extra tuft piles available at the starting and ending, protects the colour pattern piles fraying out from the core yarn. Since each chenille yarn is 41.91 cm in length containing three repeats of colour pattern and the warp is set with 28 cm in width, one and half picks could be woven from each chenille yarn. In 28 cm width, two repeats of colour pattern get set horizontally which was woven vertically in the first process. This results in forming the figure as designed in Fig 3. The next chenille yarn of the first set is woven in continuation of the earlier one that gets completed in the middle of the total width.

It is observed that six picks of chenille yarn weaving result in 1.3 cm length of fabric on loom, which is nearly equal to the size of each horizontal space taken while designing the figure (1.27 cm). Hence, after weaving six picks with the first set of chenille yarn (set A), the next six picks are woven with the second set of chenille yarn (set B). Similarly, it is continued serially in the order of A to F, and then from F to A, which results in completion of one repeat of 15.6 cm length of fabric having a set of two repeats of figures in width way, as designed in the first stage of designing. Again by repeating from A to F and F to A, the second repeat is woven to complete 31.2 cm length of fabric in total. The total number of picks woven in full length is 144 (6 picks per group x 24 groups). Fig. 6(b) shows the final velvet chenille pile table mat fabric produced from second loom after completing the weaving of all the picks. The reverse side of the fabric, which is very similar to that of the face side, is seen in Fig 6(c). The size is 28 cm width x 30 cm length on table and contains 2 x 2 repeats of design as shown in Fig 3.

Summary of quality particulars

The fabric weighs 83 grams and its thickness is one cm. The number of tufts in 1.27 sq cm is 420 (70 x 6) because there are 70 tufts per 1.27 cm in each pick and six picks are woven in 1.27 cm length of cloth. Therefore, the number of tufts per sq cm is equal to 260, out of which nearly 130 are seen on the face side and 130 on the back because of plain weave.

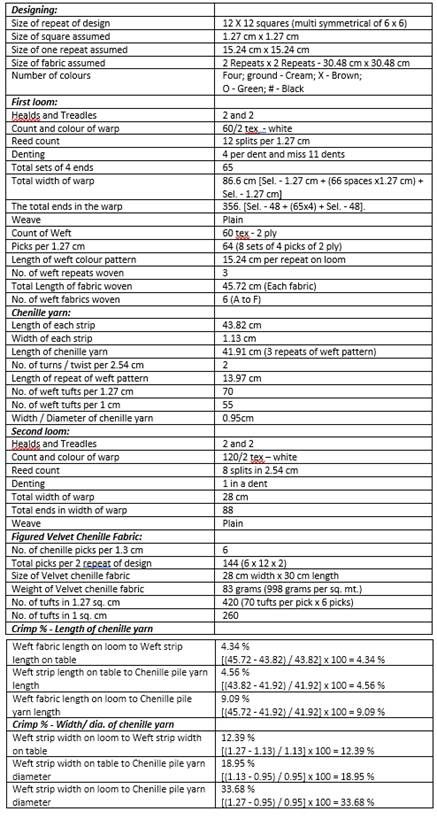

The summary of designing, weaving and quality particulars of the sample development as explained above is given in Table 4. Finally, percentages of crimp occurring in different stages are also calculated from the recorded particulars and indicated in Table 4. The crimp percentage of weft fabric length on loom to weft strip length on table, weft strip length on table to chenille pile yarn length and weft fabric length on loom to chenille pile yarn length were calculated as 4.34 per cent, 4.56 per cent and 9.09 per cent respectively.

The crimp percentage of weft fabric length on loom to chenille pile yarn length (width of chenille fabric), which was estimated as 9.09 per cent, was useful in deciding the size of motif to be taken to achieve definite size of fabric. In the second sample development with the same count of yarn, to get 10 cm width of repeat in the final fabric, the motif repeat is taken as 10.9 cm. The calculation of weft pattern is made based on 10.9 cm.

Similarly, the crimp percentages of weft strip width on loom to weft strip width on table, weft strip width on table to chenille pile yarn diameter, and weft strip width on loom to chenille pile yarn diameter were also calculated as 12.39 per cent, 18.95 per cent and 33.68 per cent respectively. The crimp percentage of weft strip width on loom to chenille pile yarn diameter, which was estimated as 33.68 per cent, was useful in deciding the width of each strip to be taken on the first loom to get a definite diameter of the chenille yarn. In the second sample development of same count of yarn, to have 0.75 cm as diameter of chenille yarn the width of strip taken on loom is 1.00 cm.

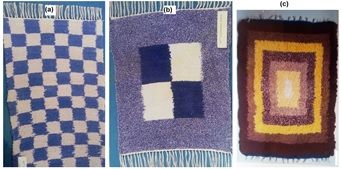

Fig. 7 - Three different figured velvet chenille pile table mats

Apart from the sample developed with six different patterned chenille pile yarns as above, three more samples, as seen in Fig 7 were developed. The first sample seen in Fig 7(a) was produced by having only one pattern of chenille pile yarn and the second sample seen in Fig 7(b) was produced by having two different patterns of chenille pile yarn. The third one seen in Fig 7(c) was woven by having seven different patterns of chenille pile yarn.

Table 4 - Summary of designing, weaving and quality particulars

Conclusion

From the study, it is observed that FVCPF could be produced as per the targeted motif by following a systematic procedure. It is also evident that producing FVCPF is economical than FCCPF because of many reasons. One is weft fabric weaving and chenille yarn setting is carried in plain weave unlike leno weave and special weave of double beam system used in producing FCCPF. The second is simple cutting and twisting operation is followed in preparing round chenille yarn unlike going through heat, moisture and pressure setting processes for preparing V-shape chenille yarn.

Further, a simple power loom or handloom set with weft pattern weaving mechanism and cutting mechanism can be very well used to produce weft patterned strips directly, which can be twisted by simple motor operated charkhas to produce patterned chenille pile yarn.

For final weaving, simple handloom is very useful to weave the patterned chenille pile weft by inserting the chenille weft pick by pick with simultaneous adjustment and setting of figure formation similar to weft yarn tie-dye weaving. The FVCPF is a reversible figured plain fabric, whereas FCCPF is one sided and non-reversible. Therefore the decentralised power loom and handloom clusters together can very well take the production of figured velvet chenille pile fabric to manufacture diversified high-quality products like carpets, table mats, door mats and bathroom mats.

About the Authors: R G Panneerselvam and K Gowri are from the Department of Fashion Technology, KCG College of Technology, Karapakkam, Tamilnadu and M Anandan is from the department of weaving, Indian Institute of Handloom Technology, Bargarh, Odisha.

Acknowledgement: The authors are indebted to the Indian Institute of Handloom Technology, Salem for their cooperation to develop samples and also to the department of fashion technology of KCG College of Technology for carrying out the analysis.

References

1. http://www.dsource.in/resource/carpet-weaving-bhadohi/bhadohi

2. https://www.contrado.co.uk/blog/what-is-chenille

3. https://en.wikipedia.org/wiki/Chenille_fabric

4. Nisbet H, Grammar of Textile Design, (D B Taraporevala Sons & Co. Pvt. Ltd., Bombay), 1985, 518.

5. Ortlek H G & Uiku S, Indian J Fibre Text Res, 29 (3) (2004) 353.

6. Grosicki Z J, Watson's Advance Textile Design (Woodhead Publishing Limited, Cambridge, England), 2004, 419.

7. Sungmin Kim, Joon Seok Lee, New production method for a plain weave figured fabric (2011), http://link.springer.com/article/10.1007/s12221-011-0137-x.

Comments