Abstract

Cotton ham fabrics can be dyed with natural dyestuffs obtained from waste hazelnut leaves in different colours and shades. In this study, natural dyes obtained by extraction of hazelnut leaves were dyed by using five different mordant materials produced from 100 per cent 30/1 raw cotton fibre. After painting, colour scales were formed and fastness studies performed. The colours obtained can be used easily in cotton knitted fabrics in terms of washing, rubbing, perspiration fastness and pilling. In formaldehyde, heavy metal and azo dyestuff tests, formaldehyde heavy metal and azo groups were not found in the products.

Input

We aimed to determine the colours obtained from dyeing cotton knitted fabrics with hazelnut leaves by applying mordant free and co-mordant method and to find the fastness values of the colours obtained from the colour palette. At the same time, the effect of the increase in the amount of mordant on dyeing was also examined and its effect on fastness properties examined.

Materials

• Five mortars of the hazelnut (Corylus avellana L.) plant in autumn

• 30/1 single jersey cotton fabric

• potassium dichromate

• Iron (III) chloride, copper (II) sulphate, tin chloride, aluminum potassium sulphate

• Corylus Avellana leaves collected from the vinicity of Yazılıgurgen village of Karapurcek district of Sakarya province

Method

To obtain natural dyestuff, 15 grams of hazelnut leaves were first boiled in 500 ml of water and then left to cool for a day. 30/1 single jersey 100 per cent cotton fabric was used for dyeing. From the natural dye stock solution, it was dyed according to the mordant technique by processing based on the dyeing chart in the ratio of 1:20 liquor. The dyeing process was completed by performing cold and hot washing. Dyeing was started by placing the fabric, dye solution and mordant in the sample dyeing machine at room temperature. It was processed for 60 minutes at dyeing temperature. It was overflowed with cold water and then washed and dried in the oven.

Findings

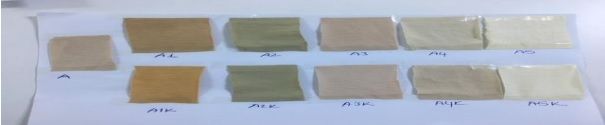

Figure 1 : The Resulting Colors

It was seen that the colours obtained are commonly used in the textile industry. Light medium and dark colours can be obtained with the dye solution obtained as a result of the extraction. When the mordant substance used changed, the resulting colours also changed.

Washing fastness of the sample without mordant gave better results.

When we evaluated the rubbing fastness in general, the dyeing gave decent results. When the dry rub fastness was evaluated, there was no difference between dyeing with and without mordant. When wet rubbing fastness was evaluated, dyeing with mordant gave better results than dyeing without mordant.

When we evaluated the Martindale abrasion test overall, the dyeing worked well. When the abrasion test results were evaluated, there was no difference between dyeing with and without mordant. Considering the type of mordant used, copper (II) sulphate mordant material created an adverse effect on the textile product used compared to other mordant materials and causes pilling on the fabric surface.

When we evaluated the acidic and alkaline perspiration fastness results, the dyeing gave good results. When the alkaline perspiration fastness results were evaluated, there was no difference between the dyeing with and without mordant. When we evaluated the mordant type used, it was observed that all the mordant varieties had the same effect.

Outcome

Colour diversity is provided with different mordants. In addition, its fastness to use gives good results. In general, it has been found that hazelnut leaves are a decent source for dyeing cotton fabric.

About the authors: The authors work at the Akar Tekstil research and development centre, Izmir, Turkey.

References:

[1] Öger Adem "1st International Nevsehir History and Culture Symposium Proceedings", Nevşehir University Press, Nevşehir, 2011

[2] Bakraç Meryem and Akdan Fatma "Comparison of wool dyeing and fastness values with various mordant methods from red ground pepper (capsicum annum l.) And tomato (lycopersiconesculentum)" "TÜBİTAK-BİDEB Research Project Training Workshop, Malatya, 2012

[3] Seyitoğlu Salih Mehmet "Removal of methylene blue from aqueous solution with some biosorbents", (master's thesis, Dicle University, 2011), 5

[4] Hıdır Recep "Tirebolu cloth; Produced for sustainable living ", International City and Health Congress, Bursa, 2018

[5] Çimen Emrah '' Obtaining natural dyestuffs from red rose leaves with different extraction methods and their applicability in the field of textile '' (Master's thesis, Yıldız Technical University, 2013), 3

[6] https://www.potasyum.gen.tr/potasyum-dikromat.html (29.11.2018)

[7] https://tr.qwertyu.wiki/wiki/Tin(II)_chloride (30.09.2019)

[8] Kızıl Süleyman and Kayabaşı Nuran "A study on the determination of the dyeing properties of love flower (resada lutea l.)", Akdeniz University Faculty of Agriculture Journal, 2005, 195-200

[9] Oğuzkan Bayıl Sibel et al. "Determination of biological activity in green bark and leaf extracts of hazelnut (corylus avellana l.), KSÜ Doğa Bil. Journal. 19 (4), 373-378, 2016

[10] Karahan Aynur et al. "Hazelnut bacterial blight in the Black Sea region [xanthomonas arboricola pv. corylina (miller et al.) vautern et al] "Studies on the prevalence of disease", Plant Protection Bulletin, 2013, 53 (3), 159-174

[11] Tutak and Friends "Investigation of the wool dyeing property of natural dyestuffs obtained from some plants", BAU FBE Journal, 2008, 10 (2), 53-59

[12] https://www.findik.gen.tr/findik-yapragi.html (15.11.2018)

[13] Tarakçıoğlu Ceyhan and Friends "Determining the nutritional status of the hazelnut plant (corylus avellana l.) Grown in Ordu region by soil and leaf analysis", Journal of Agricultural Sciences, 2003, 9 (1), 13-22

[14] '' Cotton Report for 2017 '', Ministry of Customs and Trade, General Directorate of Cooperatives, 2018, 1

[15]https://tekstilsayfasi.blogspot.com/2013/01/pamuk-physikal-kim Kimyasalozellikleri.html (02.08.2014)

[16] http://www.askimya.com/urunler/demir-3-klorur-106.html (01.10.2019)

[17] Akyatan Gizem "Investigation of the treatability of organized industrial zone wastewater by magnesium flocculation and comparison with classical coagulants", (Master's thesis, Çukurova University), 2010

[18] https://www.asit.gen.tr/bakir-sulfat.html (10.10.2018)

[19] Alhalab Khalil '' Syria and comparative examination of the cotton fiber produced in turkey '(Master's thesis, Cukurova University, 2007) 40-50

[20] Erkan Murat "Producing yarn and fabric from synthetic fiber blends compatible with cotton fiber and comparing their properties", (Master's thesis, Süleyman Demirel University, 2013) 2- 8

[21] Prof. Dr. İnci Başer Fiber Knowledge (Marmara University Revolving Fund Management Technical Education Faculty Printing Unit / İstanbul: 2002) 37-45

[22] Dabak Salih et al. "Production of iron (iii) chloride, iron (ii) sulphate in Erdemir", Ereğli Demir ve Çelik Fabrikaları T.A.Ş Laboratories Directorate, Ereğli Demir ve Çelik Fabrikaları T.A.Ş. R&D Directorate, Ereğli / Zonguldak, 2015

[23] http://www.mimibook.com.tr. (2018)

Comments