Preparing for Post-Pandemic Market Opportunities in Advance

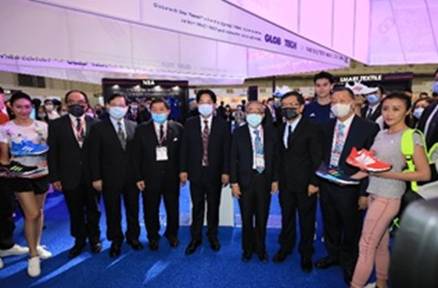

Organised by the Taiwan Textile Federation (TTF) and under the auspices of the Bureau of Foreign Trade, Ministry of Economic Affairs, Taipei Innovative Textile Application Show (TITAS) closed with success on October 15th. Despite COVID-19, 356 exhibitors from 11 countries and regions participated this year, including Taiwan, U.S., Sweden, Germany, Switzerland, Japan, Korea, Vietnam, Hong Kong, Singapore and China in total of 803 booths. To show the government's full support, Vice President Lai Ching-te attended the opening ceremony. He also visited the booths of leading Taiwanese manufacturers including the Formosa Plastic Group, Far Eastern New Century, Eclat Enterprise, New Wide Industrial, Yi Shin Textile Industrial, Tex-Ray Industrial and more in the company of Wen Yuan Wong, Chairman of Taiwan Textile Federation, Douglas T. Hsu, Honorary Chairman of TTF, Lin Chuan Neng, Vice Minister of Ministry of Economic Affairs, and Lee Lien-Chuan, Vice Minister of Ministry of Culture.

Due to the travel restriction and closed borders during the pandemic, TITAS has integrated online and offline measures to help exhibitors explore more business opportunity which include on-line catalogues, virtual one-on-one business meetings, live streaming videos and more. For example, TITAS invited more than 40 brands from 15 countries to participate in physical and virtual one-on-one business meetings with around 100 exhibitors, TITAS produced live interview videos for 16 exhibitors with innovative products and technologies to stream online. The high attendance for Medical protection textile joint presentation and Taiwan high performance functional textile application presentation proved their success. These events meant as a starting point to build the domestic textile products supply chain in Taiwan and to drive up the industry development. Statistics from TTF indicated that during the 3-day event, about 32,000 visitors attended with business potential of estimated 30 million US dollars.

COVID-19 brought opportunities for Taiwan textile industry. By modifying their production lines to produce protective textile products, Taiwan textile suppliers created more business opportunities as the result. This year, TITAS showcase post pandemic-related products which are highly innovated in "Personal Protection", "Functional Applications" and "Sustainability". On the other hand, Taiwan textile industry is also capable to immerse textile products with lifestyle and fashion aesthetics. Some of the show highlights include:

-

Formosa Chemicals & Fibre Corporation (FCFC)introduce chitin-derived fibers and compound fibers with anti-bacterial, mildew-proof, deodorant features with proven anti-bacterial results up to 99per cent. Besides protecting personal wellbeing, the organic and biodegradable properties are friendly to the environment.

-

Far Eastern New Century Corporation (FENC) was fully supportive of the supply chain for surgical face masks with its special FENC Hy care Staple Fiber series. FENC produced 600 tons of this sheath & core bi-component bonding fiber each month, equivalent volume of 1 billion facemasks.

-

Formosa Taffeta Co., Ltd. (FTC) introduce trench jackets and pants with NEGA-STAT - a compound treatment of anti-bacterial and anti-static developed in response to the pandemic to provide better personal protection.

-

Eclat Textile Co., Ltd. introduce their incredibly refined Soft form which cut down production processes but with special construction designs and material, it offers three main innovative functions that are "light weight and permeability", "flexibility and comfort" and "keeping warm in winter".

-

Nan Ya Plastics Corp. (NPC) present SAYA Recycled Polyester Filament. Nan Ya actively develop recycled oceanic filaments and recycled yarns made by collecting overstocked greige and fabrics as the starting points for circular economy.

-

Tairyfil carbon fiber developed by Formosa Plastic Corporation is a carbonized filament that can be used in a wide spectrum of applications, including sports goods, wind turbine blades, automobile, cable core and construction reinforcement, uses in high pressure gas cylinders for fuel-cell electric vehicles.

-

Green Defense and Soft Cool Clean by New Wide Enterprise Co., Ltd. are anti-bacterial and odor-control fabrics. Silver ionic fibers are beneficial for stimulating circulation and anti-bacterial function.

-

Yi Shin textile's new generation of Magic BES(Biodegradable Enhancement Solution) materials can expedite biodegradable process of waste synthetic fibers or recycled products to with micro-organisms in anaerobic or aerobic environments to avoid secondary pollution from recycled materials.

-

Grande Tex's signature RICH-y dope dye yarn can effectively cut down energy waste from dyeing processes. It is also equipped with long-lasting anti-bacterial, odor control, anti-UV and energy saving properties.

- SINGTEX PROTECTOR and bio-based coffee membrane AIRMEM-X by Singtex Industrial Co., Ltd. with medical protection and sustainable properties, are made with industrial wastes and bio-based coffee oils. These are perfect combination of fashion, eco-friendly and pandemic prevention.

Another two main themes in TITAS are "Smart Textile" and "Smart manufacturing". Some of the key exhibitors include:

-

A Smart Thermoregulation Clothing by FTC is the result of cross-industry collaboration, combining efforts from the textile, telecommunication, electronic and garment industry. FTC A Smart thermoregulation materials can be monitored through mobile devices such as tablets, smart watches and smartphones to regulate the thermal and light-emission features on the garments to provide safety signaling functions.

-

Tex-Ray has invested in development of smart garments for years with products that can be used in sports training, outdoor activities or remote care. These products are trendy, smart, and functional, brining brand new experiences for the users.

-

iQmax Wireless EMS Textiles, a technology that combines fiber with electronics. The wearable technology market apply smart textiles, garment finishing and components like pressure, temperature, touch panel another features to enhance personal protection, heath care, comfort, and the garments can be more interactive and responsive to the wearer.

-

Oshima Co., Ltd. brought a competitive edge to Taiwan's manufacturing technologies. Solutions from Smart Automatic Cutting Machine Series J3 and M8S can increase the capacity of protective garments from 2,700to 16,200 pieces per day. Oshima have become the key partner for international garment manufacturers.

-

MEGASEW Sewing machines are equipped with features like bright board with light under the fabric, needle bar hidden oil seal design, and direct drive computerized mini servo motor design. With these features, products are eco-friendly, user-friendly, highly efficient, and aesthetically pleasant, offering high-quality results for discerning major brands.

TTF has announced that TITAS 2021 will be held at the Taipei Nangang Exhibition Hall from October 13-15. TITAS will continue to assist our exhibitors to develop international markets so Taiwan can be the manufacturing and developing center for high-end textile products in Asia!

Comments