The fashion industry is said to be a top polluter accounting for 10 per cent of the global greenhouse gas emissions. The outbreak of the pandemic has only accelerated the need for sustainable fashion.

Imagine this - you just bought a pair of expensive shoes a few months ago but now they've worn out and you have no other option but to buy a new pair. Do you often feel the need to replace things, only because they get worn out easily? Well it isn't you only. Things are designed that way. They are made to be discarded. The "throw-away" human society is strongly influenced by consumerism. The term "throw-away" describes a critical view of overconsumption and excessive production of short-lived or disposable items over durable goods that can be repaired. [1]

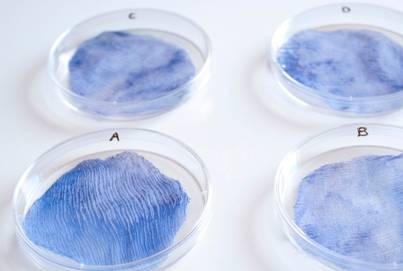

Bacteria dyed silk

The most common model of manufacturing almost everything in the world, is a linear model. In such a model, raw material is sourced from a certain place in the country, transported to a manufacturing unit, processed, and the final product is shipped to the sellers. The customer buys it, uses it, and finally discards it. This way about 99 per cent of the stuff we buy ends up in landfill.

Every year, we humans dump 2.12 billion tonnes of waste. One can clearly see the shortcomings of this system, by looking at the textile and apparel industry.

The fashion industry contributes 10 per cent of the global greenhouse gas emissions due to its wide use of resources and energy intensive production. It is the second most polluting industry in the world. About 20,000 litres of water is used in the production of a single t-shirt and a pair of jeans. The industry is said to emit more carbon than international flights and maritime shipping combined. Globally, 80 per cent of the discarded textiles goes into landfills and can take 200 years to fully decompose and as it decomposes, it emits methane-a greenhouse gas more potent than carbon.

Mushroom mycelium fabric samples

Mushroom mycelium fabric samples

Hence, the need of the hour is to move towards a circular model of production, wherein the products are designed in such a way that maximum portion of the discarded items can be retrieved through recycling, refurbishing or repairing. It works on the principles of sustainable design strategy, zero-waste design, product-life extension, resource recovery, repair and remanufacture services. [2]

In recent years, talk on sustainability has gained traction and people have started making conscious efforts to be mindful of the environment. Concepts like thrifting and buying secondhand clothes are also gaining momentum. But greater change can be brought, if we change our ways of mass production and the "fast fashion" mentality.

New trends have brought up the topic of sustainable fabric. These can include either thoughtfully designed, good quality, material that can last long, or it can show the advantage of using environment friendly materials such as hemp, bamboo, organic cotton, khadi etc.

Fashion designers have already started exploring the possibility of biodegradable textiles made of materials like algae, mycelium, fungi, bacteria, etc, which when thrown away, break down into nontoxic substances. The major benefit of this is that they can be grown into moulds and hence the designer grows only the amount of fabric that is required, which considerably reduces waste, right at the production level.

Scoby leather, made from kombucha

A lot of these materials can be locally sourced; anyone can grow them, right in their homes.

One such material is Scoby, which stands for 'symbiotic culture of bacteria and yeast'. It has an extremely simple production method wherein sweet tea is fermented with kombucha (a fermented drink) and made to rest for about 3-4 weeks. Due to the presence of bacteria and yeast, a layer starts to develop on the top, which is taken out and upon drying, it resembles leather and has great strength. It is 100 per cent vegan material, biodegradable, customisable and economical. Organic dyes are commonly used to dye it, hence making it entirely free of toxic chemicals.

Clothes made from kombucha leather, BioCouture, Suzanne Lee

New York based fashion designer Suzanne Lee, the director of The BioCouture research project, has been actively working towards making sustainable fabric, out of kombucha. She uses microbial cellulose (composed of millions of tiny bacteria grown in bathtubs of sweet green tea) to produce clothing. The idea is to grow a dress in a vat of liquid.

With the coronavirus pandemic, we have seen thousands of people lose their jobs. A vast chunk of these people are the local vendors, artisans, craftsmen, weavers, tailors and small businesses. Going "vocal for local" holds immense importance during these times and it comes with a host of benefits for everyone involved. Primarily, it pays the workers and funds their basic needs.

Secondly, handwoven textiles are made by hand using a handloom and does not require electricity or produce any pollution. These provides weavers many ways to reduce wastage and engage in sustainable practices.

Fashion is a consumer driven industry, and it is our responsibility to be mindful consumers and rethink its impact on the earth and its ever-depleting resources. The desire for new clothes may be impossible to combat. But the least we can do is make sure we buy clothes that are long lasting, ethically sourced and sustainable.

Textile landfill

Textile landfill

References:

[1] https://en.wikipedia.org/wiki/Throw-away_society

[2]https://news.aapnetwork.net/what-is-circular-manufacturing-and-why-does-it-matter/

Comments