The increasing importance of recycled fibre processing

With barely 1 per cent of garments being recycled and three quarters of the world's clothing ending up in landfill, the textile industry is actively seeking ways to make production patterns more sustainable and pay more attention to the entire life cycle of items of clothing. Rieter is offering solutions for the integration of recycled raw material into yarn production to help close the textile loop. The results of our latest study show that it is possible to spin not only rotor, but also ring yarns of different quality with a considerable amount of recycled raw material on a Rieter system.

In recent years, better use of raw materials has become very important in the textile sector due to growing environmental awareness, legal requirements for more sustainability, and the cost of raw materials. As a result, more research and development is being carried out in the various areas of textile recycling.

Coordination and cooperation between the different industrial sectors, from the procurement of raw materials through to the new final product, will be vital. Only then will it be possible to expand and optimise the entire recycling process to help it grow into a larger market. In the next few years, the realistic market potential for the staple fibre industry for recycled raw materials amounts to around 7.6 million tons annually if the current trend continues.

Classify the raw material

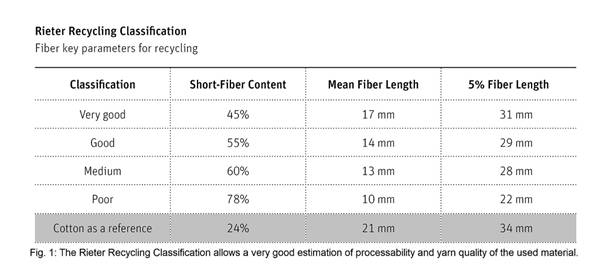

To help spinners in the area of recycled fibres, Rieter has established a classification system for the typical recycled raw material quality available in the market (Fig. 1). The Rieter Recycling Classification makes it easier for spinners to estimate what targets can be reached depending on the material. The short-fibre content, the mean fibre length and the 5 per cent fibre length are important parameters after the tearing process because they help to determine which subsequent spinning process (ring or rotor) should be used and which quality (uniformity) and maximum spinning fineness (yarn count) can be achieved.

Defining the optimal spinning process for recycled materials

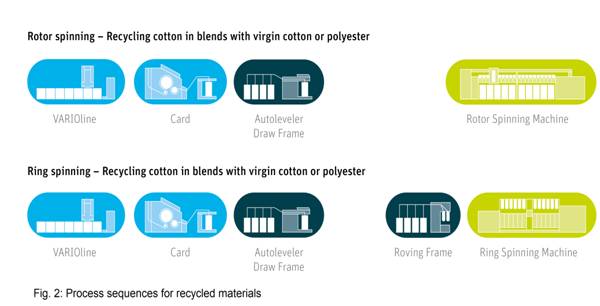

A very interesting recycling example is the re-spinning of used cotton clothes, e.g. t-shirts. Typically, the recycled raw material is blended with virgin cotton. This application was also used in the Rieter trial to determine the optimum spinning process. Both the requirements for raw-material preparation and the best machine configuration for spinning staple fibres were considered. The raw material in the trial was a blend of virgin cotton from Chad and bleached cotton recycled fibres which were mixed in varying proportions. The graphic below shows the process sequences within the spinning process (Fig. 2).

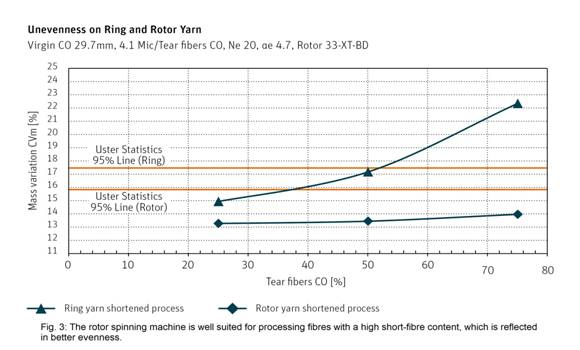

Rotor yarn has the best unevenness

In essence, the rotor spinning machine is well suited for processing fibres with a high short-fibre content (> 30 per cent), which is reflected in better evenness (Fig. 3). This is due to better fibre feeding of the opened fibres in the closed fibre feed channel and the doubling of the individual fibres in the rotor groove. For acceptable yarn quality and operational reliability, a blend containing up to 75 per cent recycled content is possible in this raw material configuration.

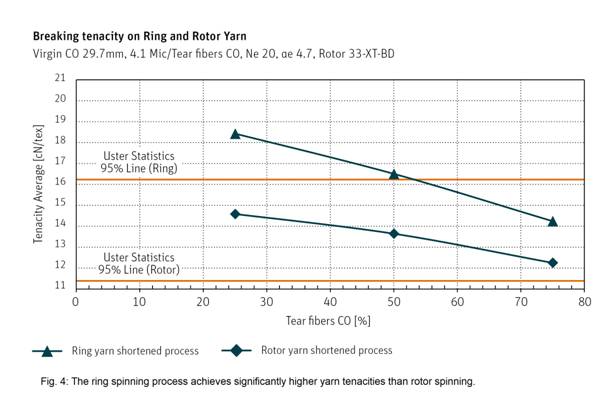

Ring yarn has the highest tenacity

Ring yarn, by contrast, has the highest yarn tenacity on account of more intensive fibre integration (Fig. 4). This opens a wider range of applications, namely the increased use of these yarns in weaving mills. Tenacity reduces as the recycled and short-fibre content increases.

Is it economical to produce yarn from recycled fibres?

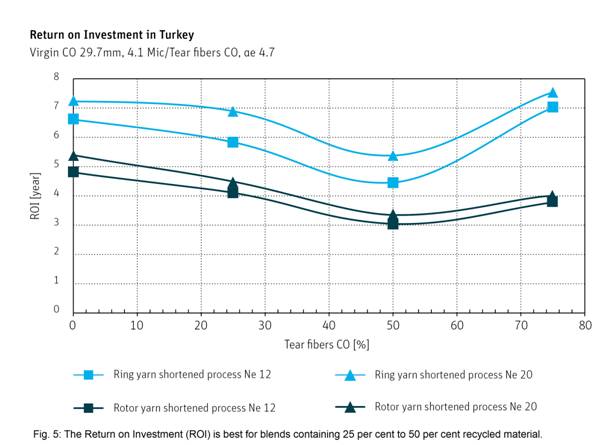

The economic efficiency depends on the proportion of recycled material in the yarn, as this has an influence on the yarn conversion costs and the yarn sale price. In the Rieter trial a yarn count between Ne 12 and Ne 20 was used and the yarn conversion costs were calculated for ring yarns and rotor yarns in Turkey (Fig. 5).

The economic analysis assumes a slightly cheaper recycled raw material price compared to a medium-quality virgin cotton. The calculation is also based on the realistic view that trade will accept a higher price for yarn made of recycled fibres. Depending on the amount of recycled fibres there is little loss of yarn or fabric quality, but raw material resources are better utilised and meet the need of many companies to become more sustainable. A blend containing 25 per cent to 50 per cent recycled raw material should therefore achieve a yarn sales price which is at least 0.1 to 0.2 cents per kg higher than that of virgin cotton raw material, depending on the end-spinning process and yarn count. Figure 5 shows that the Return on Investment (ROI) is best for blends containing 25 per cent to 50 per cent recycled material.

There will be greater or lesser scope for the economic viability of the staple-fibre yarn production process depending on whether it is a case of yarn trading or a fully integrated process. In any case, the economic analysis shows interesting opportunities for processing recycled cotton raw materials using staple-fibre yarn production.

Comments