Rieter customer Nipaş Tekstil in Turkey appreciates the combination of high productivity and low energy consumption in Rieter’s latest fully automatic rotor spinning machine R 70. In addition, possible raw material cost savings and high flexibility with different lots on each side open up new possibilities.

Rieter’s latest fully automatic rotor spinning machine R 70 sets new standards in terms of high productivity, improved raw material utilization and low energy consumption (Fig. 1). This is achieved by having independent automation at every spinning position, as well as an advanced version of the proven spinning box technology. This technology results in better yarn tenacity (typically for cotton applications) and, in many cases, allows the twist to be reduced. Because of the lower twist, a higher production is achieved without higher energy consumption. At the same time, the yarn produced is softer than the usual rough-textured rotor yarn. This applies in particular to cotton knitting yarns.

High efficiency even with high ends-down rate

The R 70 achieves great performance results with customers. One example is Nipaş Tekstil, which produces rotor yarn made from different raw materials with a fineness between Ne 8 and Ne 40. The results achieved during the market launch convinced Nipaş to invest in eight additional rotor spinning machines R 70. Nurtekin Ufakşeker, the manager of Nipaş Tekstil in Osmaniye, states: “Low energy consumption and high production efficiency were the main reasons why we chose the R 70”. The higher yarn tenacity achieved with the R 70 makes higher speeds possible.

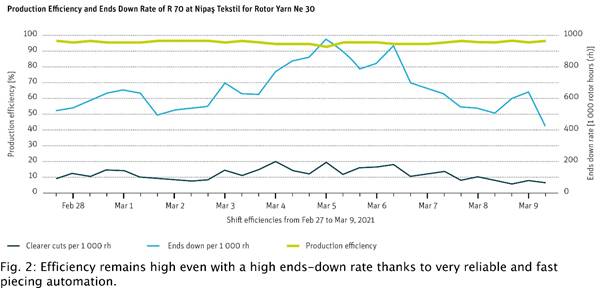

The R 70 is also characterized by high stability. At Nipaş Tekstil, efficiency remains high even with a high ends-down rate. After speeding up the rotor, the number of ends down plus clearer cuts temporarily rose above 1 200 per 1 000 rotor hours. But thanks to very reliable and fast piecing automation (Fig. 2), efficiency was not impaired.

29% lower energy consumption

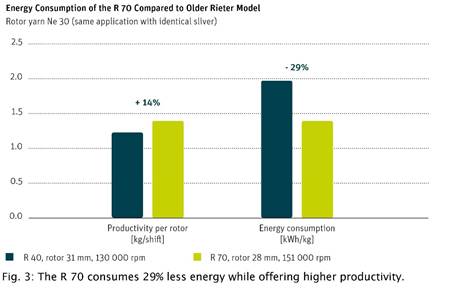

During development of the R 70, special attention was paid to the potential for reducing energy consumption – with great success: Nipaş measured 29% lower energy consumption than with the older Rieter rotor spinning machine models in its spinning mill (Fig. 3). This is due to the modern single drive technology and the use of a smaller rotor diameter. Furthermore, the R 70 contains an energy saving suction system. The air duct has been optimized throughout the machine. Familiar advantages, such as the proven intelligent filter cleaning function, have been adopted from previous models.

The low energy consumption of the R 70 derives from lower electrical losses. Nurtekin Ufakşeker confirms: “One of the biggest advantages of the R 70 is that there are no problems with heating despite high rotor speeds”. The spinning positions do not heat up as much and less effort is needed to air-condition the spinning room.

Potential raw-material cost savings

The better trash extraction of the spinning box mitigates the negative influence of trash in the sliver. This means that a cheaper raw-material blend can be used while still achieving the same yarn quality as before. The well-known and proven BYpass function has been redesigned for the R 70 and is the easiest way to influence the trash extraction. It now enables even more trash particles to be extracted. The result is fewer ends down, a cleaner rotor groove and consistently high yarn quality, even when the rotor is running for a long time.

High flexibility with different lots on each side

Each spinning position is equipped with ultra-modern, electronically controlled individual drives and an innovative automation system. This enables up to 36 spinning positions to start spinning at the same time and allows more ends down to be eliminated without significantly affecting the efficiency. Production even remains high when external influences cause a higher ends-down rate. Furthermore, this automation makes it possible to restart the R 70 within a very short time after a stop.

The R 70 is always equipped with VARIOlot 2x1, complemented by independent tube loaders, package conveyor belts and a package lift for each machine side. This enables a different lot to be spun on both sides. But there are more possibilities to increase the flexibility of the R 70: by making use of additional VARIOlot software options, the machine can also process multiple lots per side at the same time. VARIOlot allows continuous lot changes too. Each spinning position can immediately produce a new lot with different settings after doffing without production having to be interrupted unnecessarily.

The modern automation technology, advanced spinning box, modern drives and optimized suction make the R 70 a very productive, flexible and energy-efficient rotor spinning machine. Thanks to the BYpass and rotor cleaning with each piecing operation, the machine copes well with cheaper raw material. The rotor yarns spun on the R 70 offer decisive advantages for further processing, even with a higher number of ends down.

Comments