India has a rich heritage of hand knotted carpet weaving, probably originating from the ancient trade with the Middle East and Europe. The article explores the various forms of hand knotted carpets and their uses.

Carpet is a textile floor covering that combines an attractive appearance with warmth and comfort for walking, seating or reclining. Carpet furnishes diverse benefits to home and public spaces. They are used to:

• Improve aesthetics, add colour, texture and value to interiors

• Absorb noise and provide a quieter, less distracting workplace

• Insulate heat and provide a warmer, softer surface to the touch

• Reduce breakage of falling objects and injuries when people stumble

• Provide directional clues to move for safety exit and assembly point

Historically, the carpets were invented as a floor covering to protect people from adverse climate. With growing civilisation and the cultural evolution, the artistic and aesthetic value of carpets as home furnishing component and a traditional ceremonial material increased. The carpet weavings have fully or partially displayed traditional decorations and motifs. India has rich heritage of hand knotted carpet weaving, probably originating from the ancient trade with the Middle East and Europe. Over the centuries, the unique Indian hand knotted carpets spread around the globe and are fondly termed as antique carpets.

Global market of carpets is estimated to be over 100 billion USD and growing at about 5 per cent CAGR. The utilisation is growing with increased urbanisation and the standard of living. Highest consumption of carpets is in residential use as it helps enhance aesthetic value and brings in a sense of elegance to the home decor owing to the wide gamut of colour, design and texture. It is being widely used in the corporate world especially IT, banking and hospitality sectors. Recently the Indian hand knotted carpets have witnessed rising demand from the fashion savvy young generation who prefer it for blending ethnic culture with modern decor.

In India, the carpet production has a large and diversified base of about 3 lakh looms and provides employment to over 15 lakh carpet weavers. The unique and specialised hand knotted carpets are widely exported around the globe which helps earn foreign exchange, contribute to the growth of the Indian economy in general and the textile industry in particular.

The closer the weave of a carpet, the more highly it is priced. Indian carpets are woven in every possible finesse from 12 knots per square inch upwards. It is gratifying to record that one small Indian picture carpet showing Shiva dancing, continues to be seen as one of the most intricate ever woven carpet anywhere in the world, with an incredible 2900 knots per square inch.

India is the largest manufacturing hub of hand-knotted/tufted woollen carpets and rugs. We export ₹10,000 crore worth carpets to about 80 countries yearly and cater to over 40 per cent global hand-made carpet market share. The Indian hand knotted carpets are well known and widely accepted for their:

• Elegant colour patterns, sharp designs and prints

• Durability, strength, resiliency, colour fastness,

• Softness, abrasion resistance, soil resistance, cleanability

• Stain and pet resistance, odour absorption

Presently there are 9 major carpet production centres in India:

• Uttar Pradesh: - Varanasi, Bhadohi, Gopiganj, Madhosingh, Mirzapur, Agra,

• Jammu and Kashmir: - Srinagar, Anantnag, Jammu, Leh

• Rajasthan: - Jaipur, Bikaner, Tonk

• Punjab: -Amritsar

• Haryana: -Panipat

• Madhya Pradesh: - Gwalior

• Bihar: - Obra, Danapur, Madhubani

• Himachal Pradesh: -Dharmshala

• West Bengal: - Darjeeling

Bhadohi is well known for the hand knotted carpet making in India and accounts for almost 80 per cent of the production and export. With the growing market demand and the training and skill development initiatives taken by the central as well as state governments, carpet making is gradually spreading throughout the country. Generally, the carpet manufacturing involves following steps:

Wool is the commonly used fibre in Indian hand knotted carpets. The carpet wools are coarse (>33 micron), crimpy and often medulated. The wool carpets are difficult to ignite and can achieve high levels of resistance to flammability without special treatments. The typical characteristic nature of wool as soil hiding makes it unique for use in areas prone to significant quantities of soil for retaining aesthetics without appearing dirty. They respond well to cleaning and therefore the pile often recovers well from flattening.

Jute is typically used as the carpet backing fibre because of its low cost, good dimensional stability and natural appearance. Also, jute is a popular choice for the weft of woven carpets and frequently used as the `stuffer' warp in Wilton carpets. Cotton is also used as a primary backing in the hand tufted carpets.

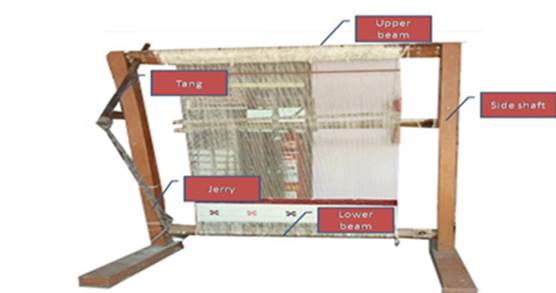

Hand knotted Carpets - This is an ancient art that deserves admiration. These are made on a specially designed loom and are knotted by hand. The size of the loom depends on the size of the carpet, thus is typically customised as per the end use requirement and the weaving is done from the bottom to the top. The artisan weaver inserts the “knots” into the foundation of the rug and ties it by hand to make a pile as per the required design. This is a skilful, tedious and time-consuming process.

• Individual yarn is tied on the hand knotted carpet

• Each yarn is tied manually to call it a pile yarn

• Knots can be made compact or loose as per the design need

Type of knots and regional demand

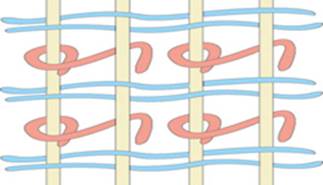

1. Persian knots for middle-east market - used in carpet making for a wide variety of utilitarian and symbolic purpose. The specialty of this knot making is its asymmetric nature, where the pile yarn (red) is placed in a loop around one warp thread (yellow) and remains loose under the other warp thread. Between every row of knots the weft (blue) is placed in one or more rows. Such asymmetrical knots make it possible to weave a carpet with higher knot density and more design details.

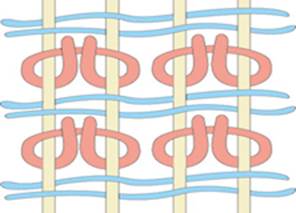

2. Turkish knots for European market - theses carpets are typically used for floor or wall covering. These symmetrical knots are also called as ‘Ghiordes’ based on its origin in Turkey. Here the yarn is placed (red) in a loop around two warps (yellow). Between every row of knots a weft is placed (blue) in one or many rows. The symmetrical knot provides a stronger consistency to the carpet and is often used for thicker carpets.

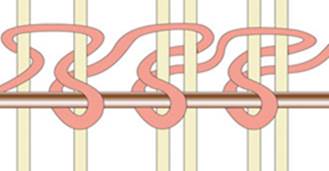

3. Tibetan knots for Asian market – these are commonly used as seating carpet and traditionally made from highland sheep wool. Here, the knot is made by using a temporary rod (brown) along the width of the carpet, which is placed in front of the warp (yellow). The long yarn (red) is then placed around two warp threads (light yellow) and then around the rod. After weaving entire row of knots the loops around the rod are cut to create the knot.

Insertion of weft 1 (thick- Thurry) and weft 2 (thin –Lachi) are added in 2 lines after a line of pile knotting. Tharri is added in the same position of pile knotting and lachhi is added after changing the shed. This weft insertion is necessary to keep the knotted pile intact and fixed.

Warping on loom - proper tension is maintain by upper beam and lower beam to impart adequate strength to the carpet. Base weaving is done by inserting a cotton yarn in the weft direction to provide support to the pile yarn.

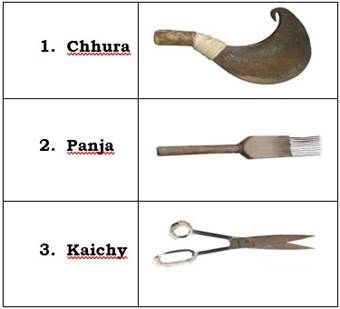

Accessories and tools

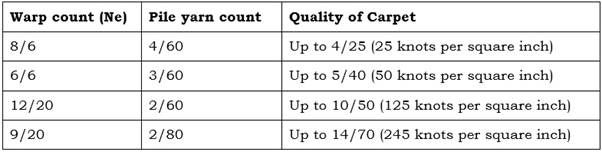

Quality of hand knotted carpets - depends on the knot density determined as knots per square inch. Higher the knot density, finer and better is the quality of the carpet. The knot density demands appropriate count of warp and weft yarn in accordance.

Carpet wear and abrasion test: Abrasive wear occurs when a hard rough surface slides across a softer surface and results in the loss of fibrous component.

![]()

Sustainability aspect – use of fibres based on natural origin, low water and energy consuming method of processing, optimum cleaning and colouration of yarn and minimal wastage of material, are considered to be important parameters which make these carpets sustainable. The cost effectiveness coupled with the aesthetic appeal and the functional performance, have enhanced global demand for these carpets.

Apart from the conventional and traditional use as home decor, these carpets are increasingly used in luxury hotels, casinos, cruise ships, corporate offices, aircraft, etc. The overall performance, durability, appearance retention, ease of maintenance, comfort and feel are the best-selling propositions.

About the authors: Raj Yadav and Dr Ashok Athalye are employed with the Department of Fibres & Textile Processing Technology, Institute of Chemical Technology, Mumbai.

References

1. Silver jubilee special; AICMA Bhadohi, 1986

2. Chauhan B. S; Encyclopaedia of carpets; 1997

3. Crawshaw G.H; Carpet Manufacture, Developments; 2002

Comments