Forty years ago, global garment industry was accused of unethical behaviour: child labour, slave-labour wages, excessive overtime, poor and unsafe working conditions. The garment industry was the poster-boy for all that was wrong with factories located in developing and least developed countries. It has taken generations to overcome the negative label. We do not want to be labelled yet again.

We are now living in a world where the vast majority of people believe that global warming is the greatest existential threat facing humanity. Regrettably, the global textile and apparel industry has once again been targeted, this time as the enemy of sustainability. The industry is accused of producing goods from non-biodegradable materials, which are invariably pushed into landfills where they will remain unchanged for thousands of years.

Textile innovation will be one of the most important factors in the new post-virus global garment industry. Even now, major forward-looking retailers/brands such as VF Corp, H&M, Uniqlo, Nike, and Adidas see textile innovation as the road to the future. The problem is that few textile professionals understand why textile innovation has become so important and even fewer understand what steps they must take to meet the needs of their customers.

Sustainability is a recent problem. For a very long time, fashion-related textiles were based on natural fibres which by definition are biodegradable. The four main natural fibres were:

• Silk

• Cotton

• Fine animal hair (wool, cashmere, angora, etc)

• Other vegetable fibres (OVF) (linen, jute, ramie, etc)

Recent innovations have introduced a fifth category, man-made fibres (MMF), which in turn is divided into two subcategories:

• Artificial (semi-synthetic): Fibres derived from natural sources such as cellulose, which includes rayon (viscose), acetate and cellophane. These date back to the late 19th and early 20th century.

• Synthetic: Fibres derived from man-made polymers including polyamides (nylon), polyacrylic, and polyester. The polyamides and polyacrylics date back to the 1920s, while polyester was developed in 1941 and first produced for clothing in the UK in 1951 under the trademark Terylene and in the US under the trademark Dacron.

The problem is that we are living in an era where we think of innovation as hi-tech development and therefore look for development through new synthetic materials.

Think Goretex and Nanofibers

Goretex: This textile product was invented by WL Gore in 1969. Goretex is a waterproof, breathable fabric membrane, that can repel liquid water while allowing water vapour to pass through. It is ideal for active sportswear including rock-climbing, sailing, and hiking in difficult climates. Although first introduced as a functional improvement, the Goretex label has become a symbol of fashion status. The problem is that Goretex is manufactured from Teflon, with the result that although you will eventually discard your Goretex anorak after 10 years, wherever your anorak is going, it will remain unchanged virtually forever.

Nanofibers: This has a long history of development, beginning in the late 19th century through the 1920s. However, it was only at the end of the 20th century that nanofibers moved from development to commercial applications. Nanofiber is used in sportswear textiles as a membrane bonded to other fabric to remove water vapour and at the same time provide a high level of water resistance. The result is a lightweight fabric suitable for cold weather activities, that again is guaranteed to last forever.

Synthetic Fabric Innovation Presents Serious Problems

With few exceptions, the promise of great innovation in fashion textiles through synthetic materials has not lived up to expectations. In the early days, we were told about clothing that would undergo colour change based on the wearer’s emotions. This is still in the dream-world category.

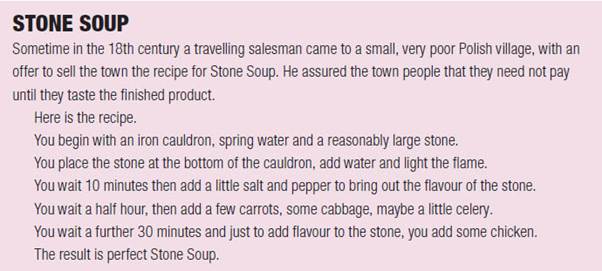

At the same time, hi-tech innovators promised garments that would produce heat as weather conditions cooled; provide the wearer with real-time health data; and the trouser telephone. These are measly gimmicks that serve no purpose. If you want to stay warm in cold weather, buy a handheld heater and put it your pocket. If you want a trouser telephone, buy a telephone, and put that in your trouser pocket. If you want real time health data, take the telephone out of your pocket, and go to the relevant app. We are too often told that the technology will be new but the underlying concept of promising something new that already exists is about 300 years old, when hi-tech salesmen of the day promised stone soup (see box).

Small heaters, real time health data and mobile phones are all readily available. Just take the device, stick it in your pocket and disregard the need for the stone.

The Innovation Revolution

The underlying problem with hi-tech synthetic fabrics is not just the failure to serve a practical purpose, it is rather that they fail to meet the needs of the industry.

While visionaries are leading us into the 23rd century, textile innovation has become an important tool in the fight to overcome the 21st century’s existential threat, i.e., global warming.

Garment making is not in itself a polluting one. The problem is not the garment-making process, but rather the product. Pollution, increased greenhouse gases, and global warming are all textile problems, because synthetic materials are not biodegradable.

Artificial materials are biodegradable because they are derived from natural materials. Here are a few examples:

• Lotus fibre: For centuries, countries such as Thailand and Myanmar have used lotus plants as the raw material for clothing. The fabric is ideal for fashion garments, giving the look and feel of a combination of silk and linen, while being stain resistant, light weight and breathable.

• Banana fibre: It is one of the world’s strongest natural fibres. It is made from the stem of the banana tree and is incredibly durable as well as biodegradable. Banana fibre derived from the banana plant stem can be used to make a number of different textiles with different weights and thicknesses, based on the part of the banana stem the fibre is extracted from. One of the greatest ecological advantages is that it is produced from wastage previously thrown away.

• Pinatex: Derived from the pineapple plant, it is the basis of vegan leather. It too is produced from wastage previously thrown away. A byproduct of the manufacturing process is organic fertiliser and biogas, which both meet the needs of the local farming community.

• Coffee grounds: These are the basis of a new product developed by Singtex, a Taiwanese textile company. The resulting coffee yarn is multi-functional and can be used in a variety of products, from outdoor and sports performance wear to household items used every day. It also offers excellent natural anti-odour qualities, in addition to UV ray protection and a quick drying time. The coffee grounds used to create the yarn are taken and recycled from some of the world’s largest coffee vendors, like Starbucks.

• Regenerative cellulose: It is a process created by NuCycl Technologies that will transform cotton waste from natural to artificial fibre. Artificial cotton can be engineered to meet specific customer demands.

As we can see from the examples above, the new artificial fibres not only avoid the problems of synthetics, but also offer previously unforeseen advantages as mentioned below:

• The raw materials already exist, thus not only providing new products but also utilising waste materials that previously had been thrown away.

• As we can see in the example of Pinatex, they offer alternatives to the present major sources of pollution and toxic manufacturing processes.

• They provide added income to local farming communities.

From concept to development to commercialisation: where do we go from here?

• The Customer Side: Retailers and brands are already investigating start-ups as well as established research centres to see the latest advances. It is only a matter of time before the retailers approach the developers with ideas of their own.

• Research and Development: Companies, institutions, and specialists with new ideas are hard at work to develop the next big thing. Among the East Asian Giants—Japan, Korea and Taiwan—government, industry organisations, and corporations are cooperating in efforts to achieve FIRST-ON THE-BLOCK status. For a long time, textiles have been a buyer’s market where rising costs coupled with ever lower FOB prices have reduced the 3-dragons’ profit margins. This is an opportunity to become leaders in the fight to reduce global warming.

For example, the Japanese are already in France marketing their latest developments to the new market for sustainable textiles:

*********

The J-Tex Showroom in Paris: where fashion professionals go to discover the latest textile innovations by Japanese companies rich in ancient know-how of excellence, and determined to meet the needs of today’s high end fashion brands.

The discovery of craft skills has the particularity of always arousing the curiosity and wonder of a local culture, climate, wisdom and techniques born in a more or less distant time. When Japanese textile know-how is exhibited in the J-Tex Showroom, the event attracts fashion professionals for a more pragmatic reason, however: The textile innovation born on Japanese lands rich in excellent craftsmanship turned towards the future.

*********

Notice the word ‘TECHNOLOGY’ is no longer in the message. It is replaced by CRAFT, CULTURE, and WISDOM.

The US is also a leader in development with small start-ups, a sector where the US excels.

Manufacturing: who gets to make the stuff?

The big-3 Asians and the EU will be major producers. On the other hand, the US which is a major player in R&D probably will not be the manufacturer of choice. It is because:

a. The US textile industry has little interest in garment related fabrics.

b. The US lacks a garment industry able to produce garments.

c. The US lacks proximity to any major fashion garment industry.

Opportunities for Others

Wanted: garment exporting country, located in Asia, with a well-established textile industry to play a leading role in the new Sustainable artificial fabric sector.

This is an opportunity to come together with reliable fashion customers, currently operating in-country to form relationships to develop the textiles of the future industry. Moderate investment required.

Comments