Consumers are looking for textiles that are not just sustainable but which provide comfort & performance

Huntsman Textile Effects is one of the leading manufacturers of high quality dyes and chemicals for the textile industry. Dhirendra Gautam, global marketing director, Dyes, Huntsman Textile Effects discusses the need for brands and retailers to become sustainable.

What is the size the of the chemicals & dyes market for textile-end uses? What is the growth rate?

The global market size for textile dyes and chemicals stands at over US$ 12 billion. The industry typically grows at a pace similar to global GDP growth, which averages a rate of 2.0 per cent year-on-year. Market growth in polyester fibres is driving growth in dye/chemical consumption for polyester, which is growing at a faster rate (approximately 3.5 per cent-4.0 per cent) unlike that for cellulosics.

What are the challenges that this niche (Chemicals for Textile- end uses) faces on the global front?

Whether it is producing high fashion garments, practical work attire and active sportswear or reliable technical textiles, our customers demand highly versatile, comfortable, colourful and durable materials that look and feel good. Across all these key segments, mills need to adhere to the Restricted Substance Lists of the world's most demanding brands, while saving water and energy and reducing production time to lower costs. Regulators are enforcing environmental laws more strictly, with mill closures and restrictions contributing to raw material price volatility.

What are the latest innovations taking place in this industry?

Consumers are increasingly looking for textiles that are not only sustainable but which provide comfort and performance levels required for an active lifestyle. These demands will continue to drive innovation in the development of products designed to meet multiple requirements. Textile Effects helps brands differentiate to capitalise on changing consumer preferences with technologies that support creation of innovative textile products with intelligent effects. These include durable water repellence and built-in freshness and sun protection.

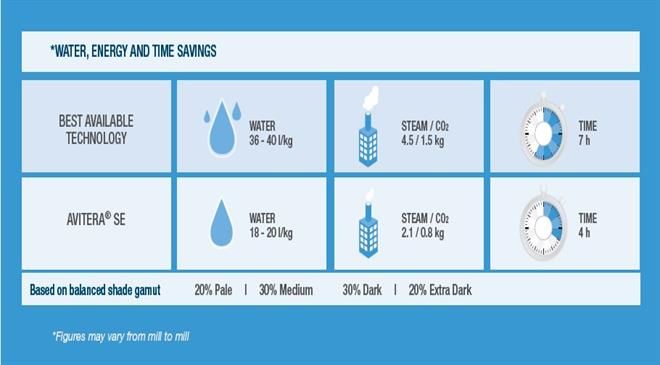

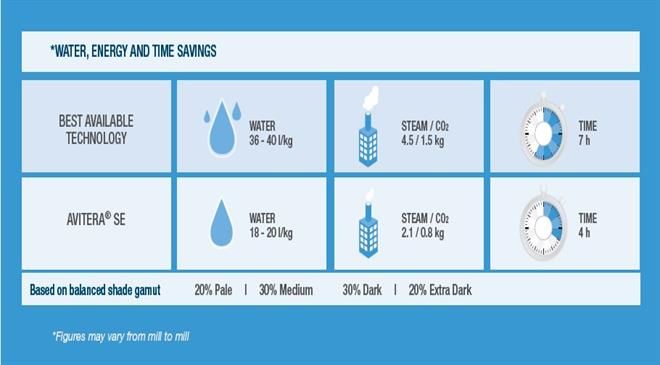

For example, Huntsman's Avitera is the first para-chloro-aniline (PCA)-free reactive dye range. Avitera SE dyes ensure rapid and high exhaustion for cotton and other cellulosic fibres and their blends. More dye is absorbed by the fabric, using less salt. Less than seven per cent of absorbed dye remains unfixed compared to between 15 per cent and 30 per cent of conventional reactive dyes. Unfixed dye is easier to remove at lower washing off temperatures as it is not bound to fabric fibres in a high-salt solution.

As a result, processing mills can dramatically increase productivity and save since dyeing and washing off cycles are substantially shorter. Less energy, water and salt are required, and carbon dioxide emissions are greatly reduced because water used in the dyeing and washing off process does not exceed 60°C. This helps our clients reduce their carbon footprints.

*Current detection limit 5ppm

Which are the better performing markets for Huntsman's textile chemicals in the last two years? Where are the prospects growing?

Asia remains the global epicentre of textile manufacturing. For Huntsman Textile Effects, India, China, Bangladesh, Central America, Vietnam and Indonesia are key growth markets. All these markets are expected to continue growing. India has developed into a large market for textile chemicals owing to the domestic production and export of cotton and synthetic fibre end articles. China is also growing though slower due to stricter environmental regulations and cost competitiveness. We have seen good growth in Central America due to near-shoring activities of brands and retailers from the United States of America.

How has your market grown in India, China and Bangladesh in the last five years?

We are market leaders in both India and Bangladesh and we continue to grow above industry growth rates. Our business for specialty dyes and chemicals is also growing in China, an important region for us. To support growth in these geographies, we have enhanced activities in research and technology centres in India and China. We continue to invest in our people and in these geographies to further differentiate our product and service offering.

What are Huntsman's textile division's future investment/expansion plans?

Huntsman is expanding its markets worldwide by focusing on delivering innovation with purpose. Our products address customers' needs to meet global textile trends and provide solutions to some of the world's greatest challenges. We focus on meeting real challenges and addressing economic and environmental sustainability, creating differentiation with our innovative products. For example, with our garment differentiation, this level of commitment and support is behind all our market development efforts. For example, Huntsman Textile Effects is at the forefront of developing sustainable, eco-friendly dyes like Avitera SE that are not only cost-effective but allow substantial reduction in the amount of water, carbon dioxide emissions, time and energy required in the dyeing process.

On the chemical front, we have developed a range of intelligent effects. These include durable water repellents involving a technology shift from harmful PFC to PFC free/non-fluorinated alternatives in apparel and outdoor textiles, freshness, colour fastness and sun/UV protection. They offer maximum safety and stringent quality. These innovations make TE uniquely positioned for value creation.

Our digital inks are used in the largest digital printing mills and machines globally. We are certified and recommended by major print head and machine manufacturers helping our customers to be more eco-friendly, deliver higher value and cost-effective products. We are constantly helping mills optimise and standardise dyeing processes to improve output and profitability through our Productivity Improvement Programme. We are committed to help customers solve their toughest challenges, maximise productivity and achieve sustainable growth.

The textile industry is striving to create cleaner and more transparent supply chains to meet regulations and consumer demands. Brands require textiles that combine excellent performance aesthetics to meet the latest trend and demands across end use markets in apparel, home and functional textiles. With Huntsman textiles, we are well equipped to offer a comprehensive range of products and services that deliver on performance and end-use requirements.

What is the percentage profit spent on R&D? What growth has this figure seen in the last five years? What new is being worked upon?

Innovation has always been absolutely critical to the growth and sustainability of the Huntsman business. We have a proven record of scientific and technological innovation. Today, the Huntsman Group has nearly 5,000 patents, granted and pending, which translate into an expanding inventory of products and an increasing presence in worldwide markets.

At TE, we have approximately 700 patents. Over 50 per cent of projects are related to environmental sustainability and 25 per cent of our products are less than five years old. We consistently invest around five per cent of turnover in research and technology. While many in our industry are cutting back, we are investing more in dyes, smart processes in our dyes, intelligent effects and more environmental friendly digital inks. We believe in delivering innovation with purpose. As emerging technologies redefine customer needs, we have to remain agile to meet their ever-changing demands in an extremely competitive marketplace.

Please tell us how Huntsman's High IQ - intelligent effects are being received by brands and mills.

Huntsman Textile Effects' High IQ global branding programme helps textile mills, brands and retailers succeed through its advanced solutions and expert consultancy and advice. The High IQ hangtag programme is the assurance that fabrics treated with our effects are sustainable textile products that will deliver the performance and benefits expected from a high quality brand.

Brands and retailers are under increasing pressure due to consumers' heightened awareness and demands for a cleaner and more transparent textile supply chain. Mills are also facing pressure to clean up their act. Government regulatory authorities in countries like China and India have been introducing tougher environmental legislation and stricter enforcement policies for several years.

A number of global brands are adopting our sustainable products. In the coming years, we expect to see more leading brands in the sports and leisure sector investing even more in sustainability.

Which textile and apparel manufacturers are proactively using sustainable chemicals and dyes?

With increasing industry pressure and stricter government regulations in many countries, most textile and apparel manufacturers across regions are becoming more proactive in the use of sustainable chemicals and dyes. Many global brands have created and designed their own extensive Restricted Substances Lists (RSLs) and have formed influential industry partnerships like the Zero Discharge of Hazardous Chemicals (ZDHC) group. This initiative, with ongoing efforts by NGOs, global brands, governments and even consumers, continue to drive change at the mill level.

What about your own facilities? How big is the carbon footprint there? Do share at length.

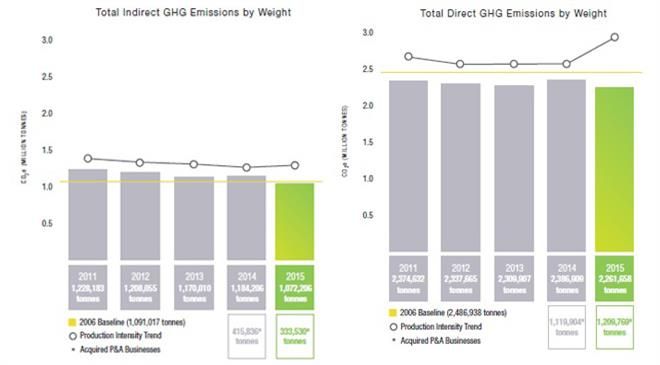

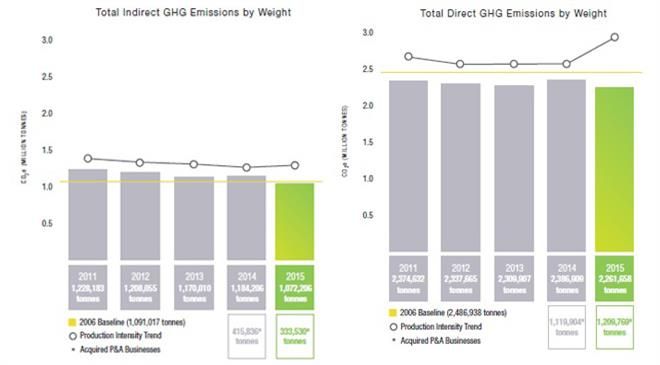

Huntsman Corporation releases an annual Sustainability Report in which it shares global performance of all facilities across its divisions. Total carbon dioxide (CO2e) emissions in 2015 were below the 2006 baseline and decreased relative to the prior year.

Huntsman's 2016 Sustainability Report is available online at: https://huntsman.com/corporate/a/Sustainability/Sustainability%20Reports

Any major events that Huntsman plans to participate or organise to promote its sustainable dyes & chemicals especially in the textile domain?

Huntsman Textile Effects participates in a range of trade shows to promote its sustainable dyes and chemicals. We were present at Techtextil 2017 in Frankfurt, showcasing a range of products including:

Avitera SE Range poly-reactive dyes that offer dramatic environmental and economic benefits to help the textile sector become more sustainable

- High IQ Repel, the most comprehensive range of non-fluorinated durable water repellent technologies that is supported by decades of application expertise and technical support

- Teratop XKS HL inks ideal for automotive digital printing and outdoor end uses that delivers full coverage of colour space and fastness requirements

- Phobol finishing based on short-chain chemistry that delivers sustainable and high-performance effects to meet industrial standards for protective clothing and many other technical applications

- Combination of Teratop and UV-Fast which is highly resistant to heat and prevents colour change during automotive processing, assembly and the whole life cycle

- Dicryclan water-based coatings for technical textiles and other high-performance applications

We participated in Performance Days in Germany where we showcased our High IQ Repel range of durable water repellents. We were also at Interdye in Shanghai, China where our dyes, chemicals and digital inks portfolio were on display.

Huntsman also actively engages with customers through customised seminars in key markets in support of the effort towards a sustainable textile value chain.

What are the pioneering sustainable processes followed at the Textile Division at Huntsman?

Sustainability, innovation and collaboration are at the heart of what we do. We use cutting edge technology to develop state of the art dyes, chemicals and inks that reduce water and energy consumption and help mills and brands create innovative end products with intelligent effects such as durable water repellence and built-in freshness or sun protection. Our goal is to support our customers and the industry to create cleaner, more efficient, transparent and sustainable supply chains.

We have rigorous processes to control the inputs, process and validate results to ensure compliance with stringent product stewardship standards from onset of product design to product end-of- life. We are working only with qualified suppliers with global levels of safety and environmental compliance standards. We emphasise on using raw materials with strict impurity limits to reduce effluents discharge. We believe in continuously engaging stakeholders including suppliers to meet stringent global safety and environmental compliance standards.