Discounting on online platforms is a major challenge for Indian apparel retailers

Numero Uno Clothing Ltd is one of India's first indigenously manufactured denim labels introduced by Hi Fashion Clothing Co. Over the years, Numero Uno Jeanswear has become a dynamic brand that fuses international trends, innovative fabrics, washes, treatments and accessible pricing. Manjula Gandhi, Chief Product Officer (CPO), Numero Uno Clothing Ltd discusses the evolution.

Apart from denims, which product category is faring well in menswear and womenswear?

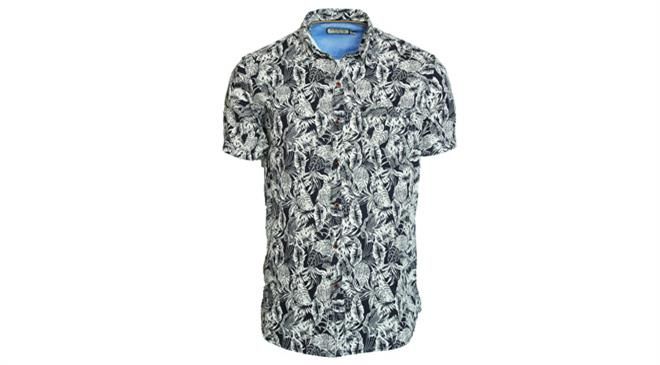

For us, denim is at the top. Denim shirts are doing really well. People are accepting denim garments besides jeans. We have denim shirts and indigo vests besides bottomwear. Our menswear shirt and apparel category are doing well.

What is the USP of Numero Uno Jeans?

USP of Numero Uno is the denim fabric. We offer global fashion, perfect fit and value for money, besides a wide collection for every season.

Please tell us about Numero Uno's journey.

Our denim brand was established in 1987. During that time, there were not many domestic players. There were very few international labels. But there was a need for denim, since people wanted to wear denims. That was the time when our Managing Director, Narinder Singh, thought of setting up a small unit and brand Numero Uno was born to manufacture denims. He began selling through small, multi-brand outlets in New Delhi.

Slowly, the brand grew. We have a wide network with our presence in a large part of the country. Although we are well established as a brand in the north, we are now expanding brand presence into other areas of the country with the help of new stores, e-commerce and large formats.

We are entirely a denim fashion brand that believes in a strong product. We try to make denims to suit changing needs and lifestyles of Indian consumers. We have come a long way from a basic five pocket pair of jeans to rugged, authentic jeans. We are a fashion conscious and fashion forward jeans brand.

The brand is experimenting with all kinds of washes, fabric drapes, fits, silhouettes and different body shapes. In India, especially, we have very different body types and the Indian customer is very conscious, knows what she or he wants, so we need to stay updated with trends, research and knowledge.

We also need to remain alert about changes in wash technology, so we have collaborated with washing experts in Spain. We keep in touch with them and buy machines with the latest technologies from them for washing and dyeing. With the latest washing processes incorporated into our denim products to move with the times, our company rises above competitors.

Do you plan to expand into markets beyond India?

We have not explored that much although we are open to expanding overseas. Small quantities of our products go to Nepal and New Zealand, especially to Indians who have migrated and have heard about our brand. They have reached out to us and want to buy and sell our products their way.

We have a regular buyer in Nepal. He buys from us during trade shows and sells there. Our products are doing well in Nepal. We have not gone out to get opportunities, but we are open to any kind of growth and any opportunity to expand our market.

Please give some information about engineered power zones in apparel that help contour the body.

When we are making the pattern for the garment, we make certain isolations and upgradation so that we can offer a perfect fit to customers. All our denims undergo our wash process. The garments we make are mainly shrunk to fit. It is not that you are getting into something that is very stiff and hard and also unwashed. When you buy a pair of our jeans, they are washed and almost like lived-in and comfortable.

What is the scope of denims in knitwear?

You must check our stores. We have a good collection of indigo knits. This knitwear is made from indigo yarn. This yarn washes just like denim jeans, it even goes through the same process as jeans. Thus, we can create all those effects that we do on denims. Once you see this collection that has the comfort of knitwear, you will feel that denim jeans can go with them.

Which points of sale are working well for Numero Uno - MBOs, EBOs, and franchisees or selling through online marketplaces?

Our EBO franchised format sells the best and also the shop-in-shop format, which is either through the MBO or the large format.

How many different products do you have within denimwear and casualwear?

In our collection, we have both denim as well as casualwear. In denimwear we offer three categories. We have forged and fashion regulars against the core, which is more basic especially for people who do not want too much happening in denim. In fashion, we offer a lot of detailing, styling and play with pockets and yokes along with that and we also offer a lot of washed denim.

In the third category which is a special range called Espana, the collection is made from the finest of washes achieved over intensive research and technology in Spain. Since the product is connected with the city of Espana in Spain, the collection is named Espania. So, this segment is again much into detailing and washed techniques. Besides denim, we have casualwear where we do shirts, T-shirts, wool dresses, sweaters and jackets. In jackets, we have a wide collection.

How big is the market for denimwear in India? At what rate is it growing?

Denim is a lucrative fabric and it is a growing segment. As per industry reports the denim market contributes five per cent to the Indian apparel market and it is growing quite consistently year on year, which makes it a good and healthy category.

The need for denim is growing as it is being accepted in the corporate set-up also. What is your take?

Denim is growing very fast in every sector of the country. There is no age bar when it comes to denim. As you can see, from children to the aged, everyone is wearing denim. This fabric has no boundaries.

People find denims are not very hard or rough, available as they are in all kinds of fabrics. At the end of the day, it is a comfortable fabric coming into activewear. Denim is already visible in jobwear. There are specialised denims made from looms, where the flexibility of knits and beauty of the washes of denim lies. So, denim is a versatile and growing segment in the apparel industry and a low maintenance fabric.

Where do you source raw materials and accessories from?

We are sourcing raw material and accessories from very selective places in India and some from abroad. Our sourcing team is dedicated and we believe in trying new channels. We keep finding newer and better sources for better quality products. However, we have good mills like Arvind Mills and KG Denims, with whom we have been working for 25 years and we have a good association with them.

How is the brand being received in Tier II and Tier III regions in India? Which towns or cities are throwing up the best revenues for the brand?

We are doing very well in these regions. In Tier II and Tier III cities, our brands are being well received. People in these towns and smaller cities accept fashion more easily and faster than in bigger cities in our network. They are ready for fashion and whatever collections we launch every season is easily picked up by them. It is great to find these new markets where you see lot of potential. You just have to find the right channels and the right people to sell your product. We can name a few small towns you may not have heard of like Narnaul and Yamunanagar in Haryana, Mandi in Himachal and Sangrur in Punjab. These may be smaller towns but are fashion-oriented.

What, according to you, is driving sales in these regions?

Everybody is connected through social media, so they are aware of what is going on in the world and what is in fashion. It is just that there is no availability so once the product is made available, it will sell even if slowly.

Getting into the market through these smaller towns is easier and penetration there is better for us. North has been a very lucrative market for us. We are already established here. Now, we are venturing into the south.

Who designs the garments? What is your design strategy? What is the strength of the designer team?

The creative team at Numero Uno is made of young designers from various design institutes in the country and some from abroad. The current creative team comprises of 12 designers. They work hard to present new ideas, new concept stories, fabric styles, colours and silhouettes and new fits that we could be knitting. Everything is brought to the table based on the forecast for every season. After we compile all the information, we like to roll everything into the collection for the season.

We study the Indian market to see what the customer would like to choose and design accordingly. We try to understand the customer's necessity, given changing needs and lifestyle, then bring the product into the market, keeping competitors in mind.

How many home-grown competitors are there in the denimwear segment? How do you stand apart?

You cannot deny that there is a lot of competition in the market. There is competition from international brands and domestic brands and from a huge organised sector. So, you have to do something different to be noticed. What works for us is international styling which is affordable, and the unique washes and good fit that we give our denim.

How has denimwear evolved as a category?

Denim started as clothing for mine workers. From there, it has moved to the top of the fashion cycle. It is the most preferred fashion item now by top most designerwear in the world. So denim has come a long way and has evolved beautifully, fitting into any lifestyle. That is because of the versatility and adaptability of denim as a fabric and as a garment.

How many collections are made in a year?

We do two collections annually.

Are consumers in cities looking beyond international brands for denimwear?

Yes, the same way as international brands cannot cater to local needs the way we can. We can understand their requirements better and fill up the gap between what is available and what is in demand.

What are your expectations from GST?

There is not much to talk about, since nothing has been declared so it is difficult to say anything. However, we would like to say that if the currency is more than the overall taxes which we are already paying, then it is going to make the difference for the branding.

How many styles do you present in each collection?

We do about 500-600 sets in a season, which comes to about 1000 collections in styles.

Last year, Numero Uno came up super light down feather jackets. What can we expect this year?

One has to be ready for the challenges and to be aware of what customers would want to stay ahead in the market. We did super light feather jackets in winter which was a huge hit.

For summer 2017, we are planning to come up with the special selection called the Zero Gravity denim. These are made from the ultra lightweight denim fabrics. They are super-comfortable and made from flexible denims. Once you wear these, you feel almost weightless. They are light, comfortable and maintain the beauty of authentic denim. You can run through daily activities freely and comfortably. These are ideal for summer. To coordinate with these denims, we have super-lightweight indigo shirts. These are already in our stores.

Please share information on your manufacturing capacity. Do you have your own units or do you outsource?

We have our own production capacity. We have a setup in Selaqui near Uttranchal, where we have a manufacturing unit updated with the latest machinery and equipment. We have collaborated with new projects, we keep buying new machineries, especially the washing ones. We manufacture all our denim, shirts, outerwear and trousers in-house. Only knitwear is outsourced. We are making about 11 to 12 lakh pieces a day. We outsource about 5 lakh pieces of knitwear a year.

What are the major challenges that Indian apparel retailers and manufacturers face?

In terms of money, discounting that is happening throughout India and on online platforms is the major challenge. All brands and retailers are offering huge discounts, to the extent that the customer is spoilt for choices and gets used to discounts.

Do you agree that Indian consumers prefer to see the product in-store first and then buy online?

Absolutely! This is only making it more difficult to retain, to sustain or to survive because their market is more integral. Apparel retailers have a huge investment in the store and they cannot offer such big discounts as online sellers. It is definitely hurting them a lot.

Even if there is a discount of 10 per cent online on the same product, it is good to enough to attract traffic. Besides the 10 per cent discount, there is a return policy, you don't have to walk around the store and spend less time. The working class mainly buys online. Rents are high, so it is difficult for retailers to have good margins. These are the major challenges apparel retailers are facing.

When you outsource, what are the top traits that you look for in a vendor?

Whether we make it ourselves or outsource, just design tactics are not enough to sustain in the market. The vendor should have been follow basic norms, be financially sound, have a good collection and contact with fabric mills. They should have professional merchants and production people to take care of quality and they should also have dedicated staff to handle the account. They should run professionally and cater to the buyer's demand and needs.

What is your strategy to counter competition, especially from the unorganised market?

Your product has to be different from that of others in the industry. We have to offer something extra so that the customer comes to us. Thus, it is product differentiation, policy and marketing which would help us counter competition.

What is your retail presence?

We have 40 company-owned stores and 162 in the new franchise format, which is a total of 202 stores.

Which is your flagship store?

Our flagship store is in Delhi. It initially opened in 2008 but now we have re-opened it in 2017 in a new location within the city after a makeover. The store now has an international look.

Which are the Tier 1, 2, 3 cities selected this year for the retail outlets? Which are the best performing stores?

North has worked the best for us. However, we are also targeting other regions and we are working on other regions. The cities that we are planning to take our products to are Kishangarh and Ani in Rajasthan.

What has the sale been like on your website vis-a- vis other e-commerce sites?

Sale has not been much on the website. We do better through our offline stores.

Which apparel/accessory category has been faring the best for your brand?

For us, denim leads the way. In other categories, it is the denim shirt. In accessories, it is footwear.