We are the only company to safely remove elastane from fabrics

US-based PurFi is a technology company making high-end products from rejuvenated textile waste streams. This technology has been commercialised for Ford, Mazda, Staples, Walmart, M&S, Sainsbury, Rockline Industries, U-Haul and Nike. PurFi recently announced a joint venture with Belgium-based manufacturing partner Concordia Textiles that integrates sustainable textile technologies and manufacturing practices to create a global circular fibre company to minimise the disposal of textile waste. Chief executive officer (CEO) Joy Nunn discusses the groundbreaking innovations and the expansion of its business model in Western Europe, the Indian sub-continent, the United States and Australia.

Tell us a little about the joint venture with Concordia Textiles. Will all regenerated fibre textiles developed at PurFi be manufactured at Concordia?

I met Concordia CEO Carl Baekelandt almost two years ago and we casually began to explore what each of us bring to the marketplace. Concordia is a global leader in the manufacture of textile-related items made of meta and para-aramids and they have been doing it for over 100 years. At PurFi, we have revolutionary technology that transforms textile by-product into high-end, final products. As the relationship grew, it became apparent that the integration of our two companies into a joint venture would be a strategic boon to both. Concordia has the expertise and savvy to rapidly expand PurFi's capacity with flawless efficiency, and PurFi offers Concordia entry into a new technological expression that broadens their global exposure; a win-win for both.

We plan to begin processing in the Concordia (Waregem, Belgium) facility, but it will by no means be singular as global expansion is a clear focus.

Who are the founders of the company? What is your business model?

I am the founder of the company. We have a true 360° business model in that we capture raw materials from brands and retailers by way of their supply chains and rejuvenate their fabrics into individualised, high quality fibres, which are then inserted back into their respective markets through end product sales. The same business model applies to post-consumer textile waste as well.

Please explain your 'rejuvenation' process that involves complex algorithms to produce fibres equivalent to virgin fibres. How much time is required? What are the steps?

Once bales of segregated raw material arrive from our collection facilities and are staged for rejuvenation processing, they are distinguished by unique mechanical and chemical data that have been programmed into our automated system. As these bales are opened and submitted to the line, fabric pieces are systematically reduced through the progression until they yield individual fibres. It is important to note that the structural integrity of the fibres is achieved by a delicate balance of both mechanical and chemical processing. No two fibre types behave the same and our processes reflect the unique characteristics of each type in the formulaic automation they are subjected to. Needless to say, our technologies are patented globally for a very good reason; they are the product of years of research and testing and are our most vigilantly guarded resource.

Our production lines are equipped to process approximately 1,250-3,000 lbs (560-1,350 kg) per hour.

How did you begin with PurFi? What kind of waste is used to make textile fibres?

I began to consider the prospect of textile regeneration in the mid-90s when I was hired by the manufacturer of adult incontinence products. The company was focused on replacing the coversheet on the adult incontinence product with cotton, but soon found that it was cost prohibitive. The concept of what they were attempting fascinated me, so I began to delve into the research and development (R&D) angle for a solution, and ultimately discovered the process for regenerating denim cuttings into fibres that were longer and stronger than their virgin origins. That experience got my creative juices flowing and I began developing sustainable manufacturing processes for the transformation of a plethora of other materials, including polyester, silk, rayon, nylon, meta and para-aramids, among others.

I discovered how to integrate these fibres into both yarns and non-wovens, where applicable. Since that time, I have developed 14 patents that cover both process as well as the modification of conventional textile machinery to execute those processes. In addition, some of the patents cover the regeneration of leather waste, as well as the technologies for composites derived from textile waste like electrostatic dissipative industrial tile and wood scrap like hydrophobic wood flooring. All of these by-product materials are clean, as it were, and simply the result of leftover stuff in the manufacturing process.

How is the waste treated before turning into fibres for re-use?

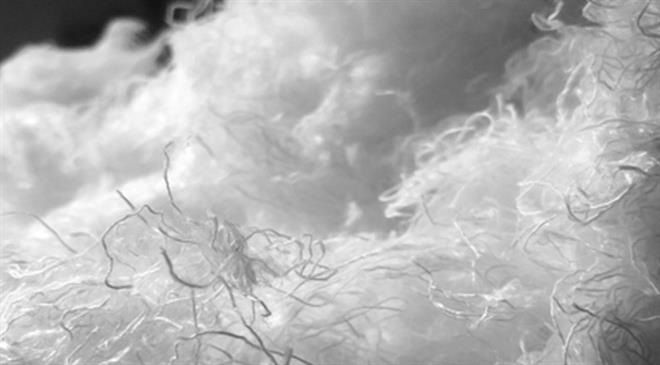

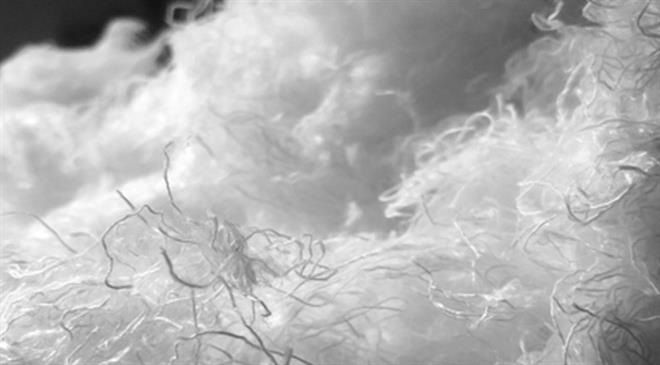

Obviously, a detailed answer won't do from my perspective in this case. In broad terms, I can tell you that we have a global, state-of-the-art collection technology in place, which is able to identify the composition and location of all our materials from their origins to their release as upcycled, high-end products (this will receive further treatment under a subsequent question heading). We sort by-product materials to align them with their regenerative processing purpose, then introduce them to the process, whereby they are treated formulaically according to their prescribed outcome. This is unique to each type of material submitted to the process and it is reflected in the corresponding automation of the line. At the end of the line, what was once scrap fabric pieces, has now become individualised fibres whose length is preserved and at times, greater strength is created than when they were in a virgin state. As stated earlier, these fibres may now be spun or made into filament yarns, or integrated into non-wovens, depending on their specifications.

What are the new areas you are researching related to rejuvenating industrial waste?

Our latest project has been undertaking the removal of elastane, which gives cotton or other garments that stretchy feel, finish on fabrics. Nowadays it seems that almost every fabric product has some degree of elastane mixed into it, even jeans and slacks. Unfortunately, this makes it impossible to rejuvenate the garment because it cannot be used for filament or spun yarn. We anticipate the trend to endure, so we have invested heavily into figuring out how to remove elastane from fabrics. We are now the only company in the world capable of safely removing elastane, which allows us to take the bulk of textile by-products that others cannot.

What technology is used to process the waste into fibres and fabrics? What is the carbon and water footprint of these processes?

PurFi uses patented and proprietary mechanical and chemical processes to manufacture textile by-product into fibres and fabrics (see discussion above).

The following statistics I am about to share with you constitute a study of the sustainability metrics in processing virgin polyester, nylon, and cotton compared to PurFi's processing of the same materials in their post-industrial by-product state. Please keep in mind that our rejuvenation technology produces fibres that are minimally equal to, and more often superior to that of virgin fibres.

- Uses 99 per cent less water

- Emits 40-90 per cent fewer greenhouse gases

- Requires 90 per cent less energy

What is the strength, durability and characteristics of the fibres developed from waste?

Our patented circular technologies combine to gently open fabric and, through a series of intricate processes, render rejuvenated, individualised fibres whose strength, durability and dimension are at a minimum equal, and in the vast majority of cases, superior to their former status as virgin fibres. Traditional recycling beats fabrics up to the point of seriously debilitating the fibres so that their only applications are in downcycled products (i.e. insulation, batting, various forms of filler, etc.), or in combination with virgin fibres found in garments and other fabric-related products. The percentage of these fibres in the latter example is extremely low, but apparently enough to market as garments made from 'recycled fibres' in order to deliver a warm fuzzy to the sustainability conscience consumer. PurFi's circular fibres, on the other hand, possess the quality necessary to be spun or made into unique filament yarns, which may then be woven into fabrics, and, well, you get the picture.

Where is the waste collected from? What amount of waste is used annually to produce textile fibres and products?

PurFi's process begins with brands and retailers but is activated at the supplier generation point. We cultivate very close partnerships with these suppliers, and together have perfected an extremely efficient by-product collection process. This involves coordinated segregation of the materials from the onset and utilising our proprietary 'track and trace' (T&T) technology to add the critical element of traceability to the raw materials. Once materials are collected at their origin, T&T maintains their genealogical data until they are ultimately shipped as high-level, final products. The benefit of this process is obvious since it provides brands and retailers a 360° view of their involvement in their textile by-product and enables them to have a true circular economy. This dynamic would be impossible without the kind of specialised data T&T provides. Additionally, it is critical to have specific data on our raw materials as to develop virgin quality material, we must be aware of the types of materials we are processing. The way one cannot build high quality garments without knowing the types of fabric one is buying, we cannot build high quality yarns without knowing the types of fabric we are buying.

There are over 60 billion pounds of post-industrial textile by-product being landfilled or incinerated annually, along with 250 billion pounds of post-consumer waste experiencing the same. PurFi will process approximately 6.5 million lbs (3 million kg) of waste in 2020. By 2021, we expect to elevate that to nearly 55 million lbs (25 million kg). And the good news is that we can process any type of fibre, including nylon, polyester, cotton, rayon, silk and meta- and para-aramids.

How do you plan to scale up and commercialise the process of textile rejuvenation?

We plan to accomplish this by way of our very strong relationships with partners in operations and collections. The Waregem line will be our first in Belgium, but we are slated to build two more there and facilitate the processing of approximately 70 million lbs (33 million kg) of material. Additionally, we are finalising plans for three lines in the Asian market. Within ten years, our goal is to have 10 billion pounds of rejuvenated fibre under management with the PurFi Concordia Group and other solid partners.

What are the top three applications in the textile domain?

From my vantage point, the top three applications are textiles (apparel), non-wovens and electro-static dissipative tile (flooring). With regard to textiles, certainly the goal is to continue improving the quality of yarns and fabrics made from rejuvenated fibres to include unique blends of fibres that would otherwise be impossible due to prohibitive costs.

We will make purified fibres (medical grade) available to the non-woven industry for eliminating the need for chemical additives in upstream applications like baby care, personal care or wound care products. PurFi will likewise bring specialty fibres to the automotive industry which lower weight, enhance sound absorption and create an optimised cabin atmosphere. And finally, from contingent waste streams, we have birthed technology for the development of electro-static dissipative tile, which is required in many technologically sensitive manufacturing environs.

Who are your major clients in the textile domain? Any major collaborations with apparel retailers or brands?

You will see our collaborative efforts in the marketplace very soon, but currently I am not at liberty to disclose those relationships due to the nature of non-disclosure agreements.

What are the future plans at PurFi after the joint venture?

Our future plans embody global expansion representative of markets in Western Europe, the Indian sub-continent, the United States and Australia. We will replicate our business model similarly in each culture, while embracing our core values. Our technology, and the opportunity it provides, benefits people and the planet. When that happens, pure profit is present no matter how you define it. (HO)