Demand for our customised solutions strong in evolved markets

Weko, Weitmann & Konrad GmbH & Co KG, based in south Germany, is known for its non-contact application systems for fluids and powder. Originally developed for the printing and paper industry, the high quality systems are also used today in the non-woven, textile, foil/film, battery, wood-based panel, tissue, glass and composite industry as well as in the manufacturing of chipboards. Carolin Russ, Product Manager-Textile and Nonwoven of the company shares details about non-contact application systems.

What is global market for application systems? What is the percentage pie claimed by the textile industry in it?

There are no statistics about this, but we assume that today most products have a kind of functionalisation or treatment. Some products inside the material itself, some penetrated into material structure and others on the surface as a finishing. The same you will find in the textile industry as every final product has to meet specific demands and markets.

Do your application systems use special liquids and powders? If yes, please share details.

Compatible liquids for the WFA system are water-based, redispersible after drying, have a low viscosity (approximately < 100mPa*s), are shear stable, i.e., there is no breakage of solutions, emulsions or dispersions while using mechanical forces by the rotating rotor, form low levels of foam and result in no flaking or coagulation

Compatible powders for the WPA system are granulated flowable powders with a particle size of 10-40 µm. These are mostly natural starch powders or calcium carbonate.

What are the latest innovations in this industry?

The latest is our ProTec-encapsulated fluid application system to ensure clean work environment and to protect against harmful substances, unpleasant odours and risk of slipping.

Which are your major markets for non-contact applications systems in the textile and technical textile niches?

Weko is mainly approached for high quality products with an industrial production process with a demand for minimal, exact and reproducible applying amount. These are some of the processes in which Weko is active:

Non-woven:

a) Automotive: Lubrication of non-woven primary backings to optimise needle friction for tufting

b) Geotextiles: Hydrophilicity of non-woven geo and agro textiles

c) Hygiene: Hydrophilicity of non-woven diaper contents like topsheet, acquisition distribution layer (ADL) and core wrap

d) Medical: Anti-microbial and anti-bacterial finishing for medical applications

e) Cosmetics: Lotionising of tissue and cotton pads, application of balms like

aloe vera and silk.

Apparel/Textiles:

a) Humidifying of wovens and knits to ensure better and stable shrinkage, e.g. before sanforizing, compacting, stenter frame

b) Remoistening of wovens and knits after drying or heat treatments to return needed humidity to the fabric

c) Hydrophilic, hydrophobic, dirt and oil repellent finishing for functional apparel (for example, sportswear)

Home textiles :

a) Terry towels , bedding and comforter: application of softeners

b) Furniture: repellent finishes, soil resistance, flame retardant

c) Carpets: repellent finishes, soil resistance

d) Mattress: anti-bacterial, softener finishing, flame retardant

What are the benefits of finishing solutions using non-contact application systems?

These are the benefits:

a) No bath contamination and wash-out effects

b) No stress due to squeezing, especially for pile fabrics like towels, carpets, etc.

c) Various penetration depths depending on porosity of the fabric, especially for pile fabrics.

d) Various finishing effects like single side or both side applications. Furthermore front and reverse side finishing with different fluids is possible.

How sustainable are Weko application systems?

The following attributes are proof of the sustainability of Weko systems:

- Minimised use of chemicals, as functional substance is applied to the surface of the fabric, where it is needed.

- No bath contamination or washing-out effects, thanks to contact-less application (less waste and disposal).

- Reduced or even eliminated drying and energy consumption because of minimised application amount.

- Programmable application quantity in g/m² or per cent of the web weight.

- Repeatable constant fluid quantity.

- Highest web speeds at speed compensated quantities possible.

- Web widths up to 7m.

- Clean environment due to encapsulated systems.

- Long product life cycle and reduced maintenance/service workload.

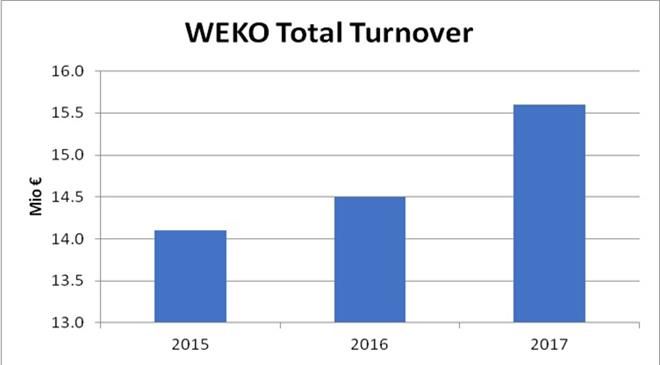

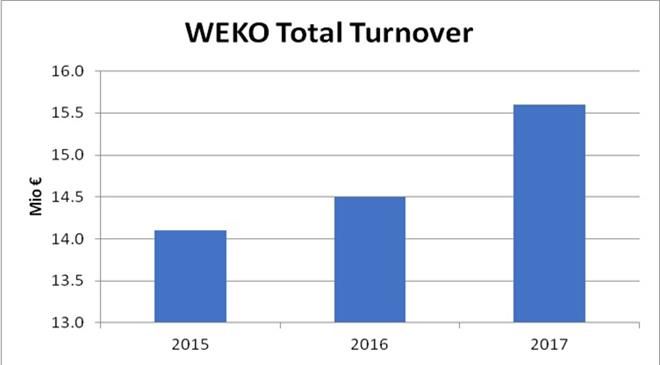

Please share details of the last two fiscals and the factors affecting your performance.

One side of our constant growth is based on product reliability and our consultancy in advance of a buying decision. This results in a satisfied customer base that speaks positive about our products and helps our brand popularity. On the other hand, we are designing customised solutions that are mostly not available with our competitors and this business is strongly growing in the evolved markets to diversify our customers business.

What are the kinds of finishing solutions that are popular among the textile industry for non-contact application systems?

The popular finishing solutions are humidifying the fabric with water and application of softeners, lubricants, spin finish, repellent finishing and anti-microbial finishing.

Which are the new fields of application for non-contact liquid?

The new application areas include functional finishing, non-wovens, technical textiles and composites (for example in automotives).

What are your thoughts on Industry 4.0? Are Weko systems integrated with IoT?

Our systems are mainly components for diverse machines. Weko offers optional access to all collected data via diverse interfaces, such as Profibus, Profinet and Ethernet. So, Weko is still usable in Industry 4.0 production environment.

What percentage of your revenue is earmarked for research and development (R&D) for the textile industry?

We could not really split our development efforts to a single industry or application as most new designed features are usable for diverse applications and industries. But as a high quality manufacturing company and technology leader, we have more than 14 per cent of our employees working in the R&D department. (HO)

What are the functional properties of Weko systems?

Weko Fluid Application (WFA) system comprises one or more Weko rotor carriers (fluid applicators) and a Weko fluid supply unit. There are different types of systems available in the Weko portfolio as well as customised solutions.

The Fluid Supply Unit provides the rotor carrier with the desired amount of liquid and controls the entire system. A frequency-controlled rotary pump transports the liquid from the storage tank to the rotor carrier for an exact defined and repeatable fluid amount. The application volume is thereby adapted to the machine speed. Liquid not sprayed can be returned to the storage tank of the supply unit.

The rotor carrier forms a defined stream of micro-droplets through the rapid rotation of spray disks, the so-called rotors. By exact defined spraying windows, the rotors create overlapping fans with a uniform liquid application.

Youtube.com/watch?v=LyQTKuY8Ugo

Benefits of the system include minimal use of chemicals, reduced or even eliminated drying costs, programmable application quantity, repeatable constant fluid quantity, contact-less application (no washing-out effects), no chemical contamination (less waste/disposal costs), highest web-speeds possible, speed compensated quantities, web widths up to 7m and clean environment due to encapsulated systems.

With the Weko Silicon Application (WSA) system, liquids can be uniformly applied to paper and optimally metered. This protects paper web and furnishes it with certain properties, such as improved sliding. Silicone emulsions, waxes and antistatic agents can be applied. The application roller, wetted by immersing it in the storage trough, applies the liquid onto the printing material. Applications include offset printing, paper processing and gravure and flex printing.

The surface is protected by applying a silicon emulsion. This increases the smoothness of the paper web and reduces static charges.

Weko Powder Application (WPA) systems are designed specifically for the preparation of a powder-air mixture and an accurately reproducible and extremely uniform powder application.

Powder is precisely applied to the material web. A uniform air flow transports the powder to the nozzles, while the control unit calculates and monitors the function of the system and adapts the amount of powder to the respective format and the machine speed.

The special nozzle geometry allows very high transfer efficiency of the individual powder particles and, consequently, less powder consumption and less dust in the environment. The release agent in sheet-fed offset, for example, uses these systems.

With conventional offset printing, a problem often develops in the delivery unit due to the drying principle. The ink is not yet completely dry, may smear and cause the sheets to stick together. The challenge is to separate the print sheets in the stack to allow the ink to dry well all the way through. Anti-setoff powders ensure a minimum distance between the print sheets after printing. The powder coat separates the print sheets reliably enough to ensure print quality and trouble free further processing.

Through exactly adjustable nozzles, spraying can be metered with precision at top speeds that each individual sheet is sprayed and not the gap in between.

Youtube.com/watch?v=NRz6Jf4XjIQ