Flowbuilt Manufacturing starts operating in US

After perfecting the technology and processes to design truly-individualised insoles and footwear, the team at Superfeet Worldwide realised there wasn't a facility to take these products from vision to reality. So they built it. Filled with prototyping materials, 3D printers and machines that flex from manufacturing a single custom pair of shoes to thousands of pairs, Flowbuilt is the place where vision becomes reality.

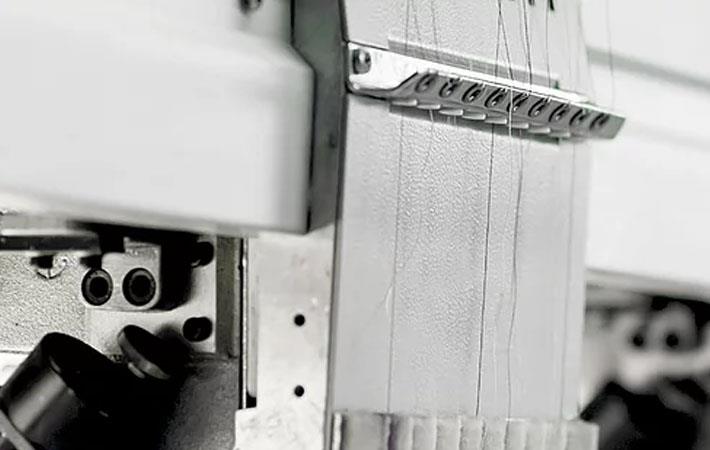

The facility helps rapid prototyping and sampling, development and design services for inline footwear and creating individualised footwear with a last size of one. Thanks to the only commercially available multi-section-injection (MSI) machine in the US, Flowbuilt partners' finished product is created with unmatched precision. MSI technology gives Flowbuilt the ability to personalise midsole responsiveness based on an individual's unique biometric data collected through FitStation powered by HP, a technology not previously available in the US.

"To date your choices have been very limited when it came to finding the best resources to bring footwear from ideation to fruition in a very quick timeframe, even more so if you wanted to do so with elements of customisation. That is, until now. With Flowbuilt our partners can utilise an end-to-end connected platform, in one location, in the US. We've created the new standard for footwear manufacturing and are setting up our partners for success by solving for problems that have yet to be discovered," states Eric Hayes, chief marketing officer at Superfeet.

With the opening of Flowbuilt, footwear brands across the globe have immediate access to solutions for the ever-evolving consumer market where being first-to-market is basically a mandate. By bringing together the forward-thinking minds behind some of the best-in-class brands, Flowbuilt partners have worked together as a team to discover best practices and perfect their process. With more than four decades of biomechanical experience, Superfeet's mission to revolutionise the way people experience footwear, Superfeet made the perfect first partner.

"As evidenced in our own experience bringing technologies like FitStation and ME3D products to market, we set out to create a clear path for brands to design and deliver their future before anyone else can. As their first partner, Superfeet is excited to push the capabilities of Flowbuilt and showcase the advanced manufacturing technologies that can be found right here in the USA," explains Chuck Sanson, director of Business Development at Flowbuilt Manufacturing.

Flowbuilt announced Brooks Running Company as its first performance footwear partner during the 2017 the Running Event trade show in Austin, TX. Brooks plans to leverage Flowbuilt's state-of-the-art multi-section injection technology to deliver the most personalised performance running shoe on the market in the coming months. (SV)

Fibre2Fashion News Desk – India

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)