Interviews

News Flash

My Size to unveil mobile measurement solution

22 Jun '18

3 min read

Courtesy: PR Newswire

My Size, the developer and creator of smartphone measurement applications, intends to unveil QSize, a mobile measurement solution for retailers to ensure quality control throughout the apparel manufacturing process. QSize will enable a retailer to fully automate its quality control process by utilising a mobile-based measurement and data logging system.

The current process for quality control within apparel manufacturing includes measurement of each garment by hand, followed by manual entry of such measurement into the manufacturer's back office system, creating a significant possibility for human error.

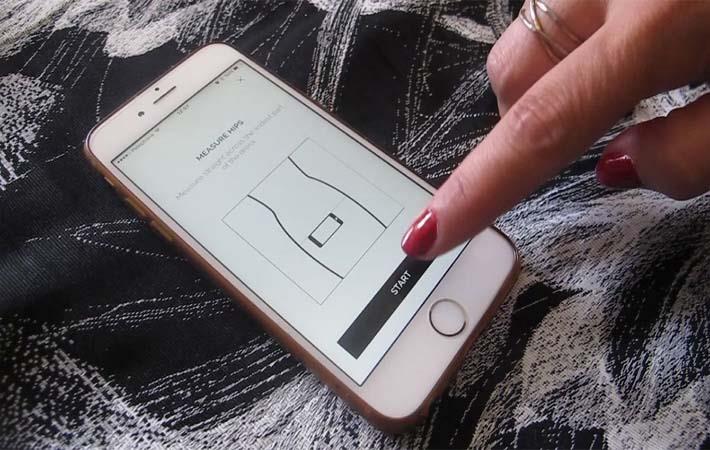

To use QSize, the user will first scan the apparel's barcode utilising their mobile device, and is then shown a graphic illustration of how to measure the garment. The user will then measure the garment with a few easy movements of the mobile device, and the data is then accurately and automatically uploaded into the retailer's back office system each and every time.

"The existing quality control system in the retail industry is antiquated and rife with opportunity for human error due to the misreading of a tape measure or incorrect data entry on a keyboard. QSize, which utilises the same innovative mobile measurement technology that powers our other products, can empower apparel manufacturing employees to perform their jobs faster and more accurately each time," said Ronen Luzon, CEO, My Size "Through the launch of QSize, we are expanding our technology offering to provide a full measurement solution for the retail industry, ensuring both the retailer and the consumer can move through their respective process as efficiently and accurately as possible."

Depending on the brand, we estimate that anywhere from 1-4 per cent of garments can be rejected at quality control for reasons including improper sizing. If such a garment cannot be repaired easily it is usually thrown away – creating an immediate and crucial need to identify errors in sizing to avoid a mass-production of improper garments. In the US, where 450 million pairs of jeans are purchased each year, an average cost of $20 per pair of jeans could result in $90 million lost to retailers.

According to a survey of people working in fashion, 94 per cent agreed that garment fit is a problem in retail and manufacturing. That same survey reported that 75 per cent said speed-to-market is the number one reason why they have increased fit issues, while 56 per cent said they could obtain a better fit for their line if they had more time in production to perfect the fit. Utilising antiquated measurement tactics such as tape measures is time consuming and slow. (SV)

The current process for quality control within apparel manufacturing includes measurement of each garment by hand, followed by manual entry of such measurement into the manufacturer's back office system, creating a significant possibility for human error.

To use QSize, the user will first scan the apparel's barcode utilising their mobile device, and is then shown a graphic illustration of how to measure the garment. The user will then measure the garment with a few easy movements of the mobile device, and the data is then accurately and automatically uploaded into the retailer's back office system each and every time.

"The existing quality control system in the retail industry is antiquated and rife with opportunity for human error due to the misreading of a tape measure or incorrect data entry on a keyboard. QSize, which utilises the same innovative mobile measurement technology that powers our other products, can empower apparel manufacturing employees to perform their jobs faster and more accurately each time," said Ronen Luzon, CEO, My Size "Through the launch of QSize, we are expanding our technology offering to provide a full measurement solution for the retail industry, ensuring both the retailer and the consumer can move through their respective process as efficiently and accurately as possible."

Depending on the brand, we estimate that anywhere from 1-4 per cent of garments can be rejected at quality control for reasons including improper sizing. If such a garment cannot be repaired easily it is usually thrown away – creating an immediate and crucial need to identify errors in sizing to avoid a mass-production of improper garments. In the US, where 450 million pairs of jeans are purchased each year, an average cost of $20 per pair of jeans could result in $90 million lost to retailers.

According to a survey of people working in fashion, 94 per cent agreed that garment fit is a problem in retail and manufacturing. That same survey reported that 75 per cent said speed-to-market is the number one reason why they have increased fit issues, while 56 per cent said they could obtain a better fit for their line if they had more time in production to perfect the fit. Utilising antiquated measurement tactics such as tape measures is time consuming and slow. (SV)

Fibre2Fashion News Desk – India

Popular News

Leave your Comments

Jason Kent

British Textile Machinery Association (BTMA)

Salvatore Piccione

Label - Salvatore Piccione

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)