Interviews

viscom shows unlimited possibilities with digital printing processes

08 Sep '11

6 min read

Modelled on microbiology

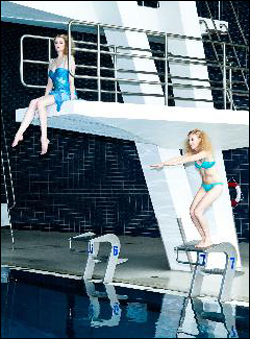

The department laboratory was also where Nadia Schiller turned her textile dreams into reality, delicate, unusual patterns in pastel and bright colours, printed in great detail on a strongly stretching Lycra mix, which is a standard material in the swimwear industry.

The underlying design ideas are not obvious at first glance, and quite intentionally so: Schiller's collection is called “Witness the Invisible”. “Microorganisms are invisible to the naked eye. The underlying idea is to bring the invisible to light, and thus to make it visible,” is how the designer describes her source of inspiration. She has distorted and creatively modified the macro photographs so as to produce the patterns for the five sub lines “Rising Harmony”, “Infinity Dream”, “Bright Emotions”, “Magical Power“ and “Donna”.

Since C&A which operates close to 500 outlets in Germany alone is looking for designs that can be produced efficiently even in large quantities, Schiller's patterns are optimised for conventional processes like rotary printing. For large production runs, inkjet techniques still remain more expensive – although, due to the enormous cost involved for producing artwork, the point at which analogue techniques start to be less costly is steadily rising. Some modern high-performance inkjets have an output of several hundred square meters per hour.

Since no expensive artwork is needed they can also produce single copies economically. For designers, however, the crucial aspect of digital printing is the fact that it removes the limitations imposed by analogue techniques: print repeats are superfluous, and so are limited colour concepts. Schiller can well imagine that in a few years time, the market will see customised swimwear produced to the wearer's specifications. The necessary technology already exists today.

viscom vom 13. - 15. Oktober in Düsseldorf mit großem Rahmenprogramm

This technology will be shown at viscom. In cooperation with the raumPROBE materials agency and Mutoh Deutschland, the newly established Customised Design Forum at viscom offers everything related to the digitally printed world. Some 150 innovative materials and samples are on display.

In the special show “Customised Design meets Materials”, exhibitors present their most innovative materials and examples of realisation in the areas of furniture, floor coverings and facades, walls and ceilings, textile and glass, as well as other material innovations, elements for the PoS and brand design. The centre piece of the Customised Design Forum is the “print design!” object section designed by various manufacturers of machinery and materials. On an area of some 100 sqm and with a great variety of exhibits, the participating companies give an impressive presentation of the options digital printing offers today.

There will also be another edition of the “From pixel to product” presentation which shows the digital workflow from digital image via image processing to the final product and the moving image. At the “Customised Printing Workshop” an entire day is devoted to the subject of customised design. Experts supply information on customising and finishing technologies, production procedures and technologies and present examples of best practice.

In 2011 viscom, which alternates between Frankfurt and Düsseldorf, takes place in Düsseldorf from 13 to 15 October. Approximately 350 exhibitors and 11,000 trade visitors are expected.

The department laboratory was also where Nadia Schiller turned her textile dreams into reality, delicate, unusual patterns in pastel and bright colours, printed in great detail on a strongly stretching Lycra mix, which is a standard material in the swimwear industry.

The underlying design ideas are not obvious at first glance, and quite intentionally so: Schiller's collection is called “Witness the Invisible”. “Microorganisms are invisible to the naked eye. The underlying idea is to bring the invisible to light, and thus to make it visible,” is how the designer describes her source of inspiration. She has distorted and creatively modified the macro photographs so as to produce the patterns for the five sub lines “Rising Harmony”, “Infinity Dream”, “Bright Emotions”, “Magical Power“ and “Donna”.

Since C&A which operates close to 500 outlets in Germany alone is looking for designs that can be produced efficiently even in large quantities, Schiller's patterns are optimised for conventional processes like rotary printing. For large production runs, inkjet techniques still remain more expensive – although, due to the enormous cost involved for producing artwork, the point at which analogue techniques start to be less costly is steadily rising. Some modern high-performance inkjets have an output of several hundred square meters per hour.

Since no expensive artwork is needed they can also produce single copies economically. For designers, however, the crucial aspect of digital printing is the fact that it removes the limitations imposed by analogue techniques: print repeats are superfluous, and so are limited colour concepts. Schiller can well imagine that in a few years time, the market will see customised swimwear produced to the wearer's specifications. The necessary technology already exists today.

viscom vom 13. - 15. Oktober in Düsseldorf mit großem Rahmenprogramm

This technology will be shown at viscom. In cooperation with the raumPROBE materials agency and Mutoh Deutschland, the newly established Customised Design Forum at viscom offers everything related to the digitally printed world. Some 150 innovative materials and samples are on display.

In the special show “Customised Design meets Materials”, exhibitors present their most innovative materials and examples of realisation in the areas of furniture, floor coverings and facades, walls and ceilings, textile and glass, as well as other material innovations, elements for the PoS and brand design. The centre piece of the Customised Design Forum is the “print design!” object section designed by various manufacturers of machinery and materials. On an area of some 100 sqm and with a great variety of exhibits, the participating companies give an impressive presentation of the options digital printing offers today.

There will also be another edition of the “From pixel to product” presentation which shows the digital workflow from digital image via image processing to the final product and the moving image. At the “Customised Printing Workshop” an entire day is devoted to the subject of customised design. Experts supply information on customising and finishing technologies, production procedures and technologies and present examples of best practice.

In 2011 viscom, which alternates between Frankfurt and Düsseldorf, takes place in Düsseldorf from 13 to 15 October. Approximately 350 exhibitors and 11,000 trade visitors are expected.

viscom düsseldorf

Popular News

Leave your Comments

Editor’s Pick

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)