ExxonMobil, ITQ find new material to separate ethylene

ExxonMobil and ITQ researchers found that the new material, composed of a uniquely structured silica zeolite, can be used in gas separation processes, such as the recovery of ethylene from ethane, with an unprecedented degree of selectivity at ambient temperature. The new material could provide insights into the design of additional materials to be used as adsorbents or membranes in a variety of different gas separation applications associated with chemical manufacturing. Results of the research have been published in the peer-reviewed journal Science.

“Cryogenic distillation, the current commercial-scale process used for ethylene separation, is an energy-intensive process,” said Vijay Swarup, vice president of research and development at ExxonMobil Research and Engineering Company. “If advanced to commercial scale, use of this new material could significantly reduce the amount of energy and emissions associated with ethylene production. This is another great example of collaboration between industry and a university that is focused on driving solutions for improving energy efficiency and reducing carbon emissions from industrial processes.”

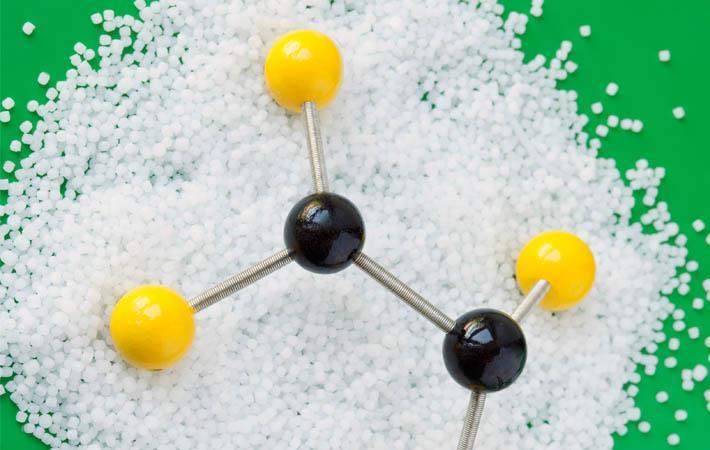

Ethylene is a critical component in producing chemicals and plastics. Finding alternative, low-energy technologies to separate ethylene from ethane has been a longstanding challenge due to their similar properties. While chemical manufacturers have evaluated a number of alternatives to cryogenic distillation, including new adsorbents and separation processes, many of these technologies are hindered by low selectivity and an inability to regenerate when exposed to contaminants.

The patented new material, ITQ-55, is able to selectively adsorb ethylene over ethane as a result of its unique flexible pore structure. Built from heart-shaped cages interconnected by flexible elongated pore openings, the material allows the diffusion of the flatter ethylene molecules as opposed to the more cylindrical-shaped ethane molecules. The new material acts as a flexible molecular sieve.

“ITQ-55 is a very interesting material whose unique combination of pore dimension, topology, flexibility and chemical composition results in a highly stable and inert material that is able to adsorb ethylene and filter out ethane,” said professor Avelino Corma of the ITQ and co-author of the research.

However, additional research must be conducted before the material can be considered for larger-scale demonstration and commercialisation. Fundamental research will continue focusing on incorporating the material into a membrane and developing additional novel materials for gas separation, ExxonMobil said in a news release. (RKS)

Fibre2Fashion News Desk – India

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)