Interviews

AATCC publishes international standard for e-textiles

20 Feb '19

3 min read

Pic: AATCC

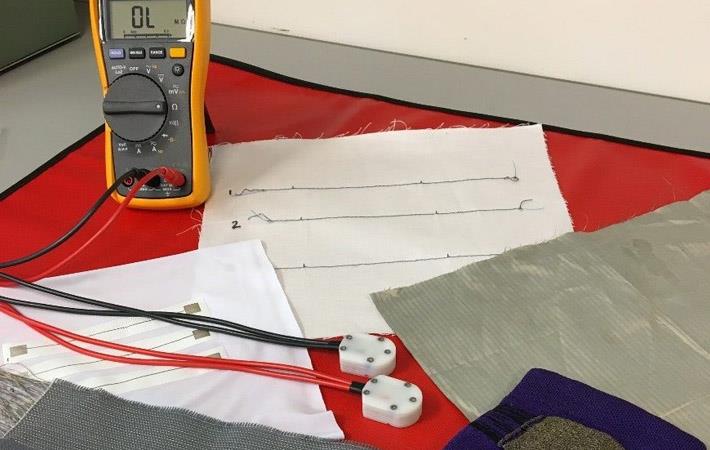

AATCC research committee RA111, electronically-integrated textiles, recently approved its first evaluation procedure. AATCC EP13, evaluation procedure for electrical resistance of electronically-integrated textiles, is one of the very first international standards for e-textiles. AATCC is the leading not-for-profit association serving textile professionals.

The evaluation procedure provides detailed instructions for measuring resistance of e-textiles, a key indicator of functionality. It also includes guidance and calculations for determining change in resistance after laundering, stretch, or other treatment, according to AATCC.

AATCC EP13 is currently available for purchase from the AATCC website as a downloadable PDF. It will be included in the 2019 AATCC technical manual mid-year supplement published this summer. AATCC standards are developed, approved, and periodically reviewed by a global team of volunteer subject matter experts. All stakeholders are welcome to participate in this consensus-based process. The standards are recognised and used around the world.

Work on AATCC EP13 began in 2015 when manufacturers approached AATCC about developing standardised test methods to allow everyone, large and small companies alike, to objectively evaluate and sell e-textile products. More than 100 people expressed interest in the subject and RA111, electronically integrated textiles test methods, officially became an AATCC research committee in March 2016. The group agreed that the first procedure should be as simple and accessible as possible—no expensive or complicated equipment.

The procedure can be performed on a variety of materials, including those with woven, knitted, printed, or stitched conductive elements. AATCC EP13 is suitable for component fabrics or complete e-textile products. It is designed to be performed in standard atmospheric conditions for textile testing and the apparatus can be purchased inexpensively from a variety of sources. In addition to being simple to perform, the procedure had to be repeatable. The committee researched and discussed the best ways to control variables such as distance, pressure, and contact area. An inter-laboratory study was performed to determine the precision of AATCC EP13.

RA111 is currently balloting two additional standards. One is a test method for laundering e-textiles and the other is a laboratory procedure for exposing e-textiles to a variety of conditions. The standard is based on existing test methods for perspiration, UV radiation, etc., with specific instructions for preparing e-textile specimens to test the change in electrical resistance. A task group is already working on a stretch test for e-textiles. Other projects include ongoing revision of the existing standards to reflect new knowledge and new technology. (GK)

The evaluation procedure provides detailed instructions for measuring resistance of e-textiles, a key indicator of functionality. It also includes guidance and calculations for determining change in resistance after laundering, stretch, or other treatment, according to AATCC.

AATCC EP13 is currently available for purchase from the AATCC website as a downloadable PDF. It will be included in the 2019 AATCC technical manual mid-year supplement published this summer. AATCC standards are developed, approved, and periodically reviewed by a global team of volunteer subject matter experts. All stakeholders are welcome to participate in this consensus-based process. The standards are recognised and used around the world.

Work on AATCC EP13 began in 2015 when manufacturers approached AATCC about developing standardised test methods to allow everyone, large and small companies alike, to objectively evaluate and sell e-textile products. More than 100 people expressed interest in the subject and RA111, electronically integrated textiles test methods, officially became an AATCC research committee in March 2016. The group agreed that the first procedure should be as simple and accessible as possible—no expensive or complicated equipment.

The procedure can be performed on a variety of materials, including those with woven, knitted, printed, or stitched conductive elements. AATCC EP13 is suitable for component fabrics or complete e-textile products. It is designed to be performed in standard atmospheric conditions for textile testing and the apparatus can be purchased inexpensively from a variety of sources. In addition to being simple to perform, the procedure had to be repeatable. The committee researched and discussed the best ways to control variables such as distance, pressure, and contact area. An inter-laboratory study was performed to determine the precision of AATCC EP13.

RA111 is currently balloting two additional standards. One is a test method for laundering e-textiles and the other is a laboratory procedure for exposing e-textiles to a variety of conditions. The standard is based on existing test methods for perspiration, UV radiation, etc., with specific instructions for preparing e-textile specimens to test the change in electrical resistance. A task group is already working on a stretch test for e-textiles. Other projects include ongoing revision of the existing standards to reflect new knowledge and new technology. (GK)

Fibre2Fashion News Desk – India

Popular News

Leave your Comments

Editor’s Pick

Ritesh Dodhia

Dodhia Synthetics Limited

Christian Guinet

French Textile Equipment Manufacturers’ Association (UCMTF)

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)