Interviews

Carnegie Mellon, Rochester Inst work on 3D printing

06 Jul '17

3 min read

Courtesy: 3ders

Scientists from Carnegie Mellon University and Rochester Institute of Technology have developed techniques for combining 3D printing with embedded textiles to create “rigid objects with embedded flexibility” and “soft materials with additional functionality.” The techniques can be used to create partially 3D printed, partially textile-based items.

It looks like a match made in heaven: textiles, packed with desirable characteristics like stretchability, twistability, and foldability, can maintain their shape when placed under tension and can be engineered with precise levels of stretchiness; 3D printing, a modern manufacturing process, can produce functional, rigid objects with complex geometries.

In a recent study carried out at Carnegie Mellon University, which has been published in Proceedings of the 2017 CHI Conference on Human Factors in Computing Systems, researchers attempted show how the “malleability, stretchability, and aesthetic qualities” of textiles can enhance rigid 3D printed objects.

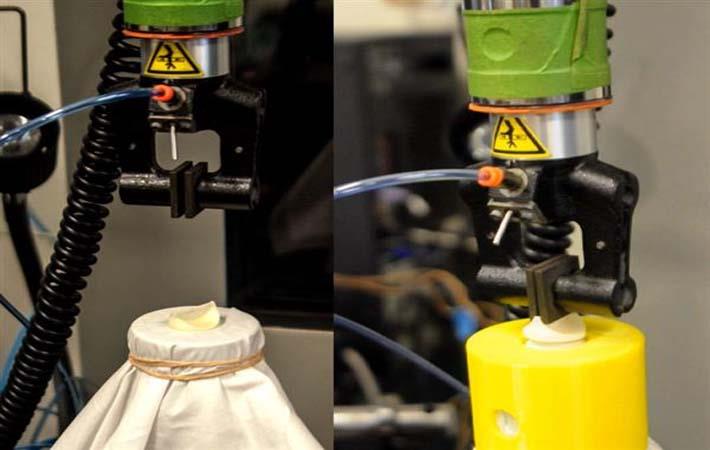

The group also looked at how textiles can be augmented with “functional properties” using 3D printing. (Think wearable tech, but with a more holistic approach to production.) In the study, the researchers carried out various experimental procedures, including attempts to stiffen textiles by 3D printing plastic elements onto them. This involved attempting to overcome the challenges of printing on non-plastic textile substrates: often, the researchers would have to secure fabric to the print bed or other surfaces to stop it sliding around when printed on.

But despite the challenges faced when mixing 3D printed plastics with textiles, the researchers managed to produce some pretty impressive example objects. These included fabric-based input devices, such as a reusable displacement sensor whose electrical components are embedded during the 3D printing process. The displacement sensor “allows custom actuation mechanisms to be quickly fabricated, snapped on top, and tried out before deciding on a final design.”

Other items produced during the 3D printing study included a six-panel fabric lampshade - one panel of which is modified to accommodate a lightbulb - and a flexible watchband, which consists of four types of plastic, two layers of fabric, and a magnetic clasp. For this wearable device, the researchers used NinjaTek SemiFlex filament and two layers of polyester mesh fabric.

The Carnegie Mellon and Rochester Institute of Technology team thinks its research could be taken up by others who might be interested in creating partially 3D printed, partially textile-based items.

“Textiles are easy to incorporate into the 3D printing process with unmodified consumer-grade technology,” the researchers say. “Although any given design requires some experimentation to be successful, such experimentation is common with non-fabric based prints as well. We are confident that others can easily adopt our techniques to incorporate textiles into their 3D prints.”

The researchers involved in the project were Michael L Rivera, Melissa Moukperian, Daniel Ashbrook, Jennifer Mankoff, and Scott E Hudson. (SV)

It looks like a match made in heaven: textiles, packed with desirable characteristics like stretchability, twistability, and foldability, can maintain their shape when placed under tension and can be engineered with precise levels of stretchiness; 3D printing, a modern manufacturing process, can produce functional, rigid objects with complex geometries.

In a recent study carried out at Carnegie Mellon University, which has been published in Proceedings of the 2017 CHI Conference on Human Factors in Computing Systems, researchers attempted show how the “malleability, stretchability, and aesthetic qualities” of textiles can enhance rigid 3D printed objects.

The group also looked at how textiles can be augmented with “functional properties” using 3D printing. (Think wearable tech, but with a more holistic approach to production.) In the study, the researchers carried out various experimental procedures, including attempts to stiffen textiles by 3D printing plastic elements onto them. This involved attempting to overcome the challenges of printing on non-plastic textile substrates: often, the researchers would have to secure fabric to the print bed or other surfaces to stop it sliding around when printed on.

But despite the challenges faced when mixing 3D printed plastics with textiles, the researchers managed to produce some pretty impressive example objects. These included fabric-based input devices, such as a reusable displacement sensor whose electrical components are embedded during the 3D printing process. The displacement sensor “allows custom actuation mechanisms to be quickly fabricated, snapped on top, and tried out before deciding on a final design.”

Other items produced during the 3D printing study included a six-panel fabric lampshade - one panel of which is modified to accommodate a lightbulb - and a flexible watchband, which consists of four types of plastic, two layers of fabric, and a magnetic clasp. For this wearable device, the researchers used NinjaTek SemiFlex filament and two layers of polyester mesh fabric.

The Carnegie Mellon and Rochester Institute of Technology team thinks its research could be taken up by others who might be interested in creating partially 3D printed, partially textile-based items.

“Textiles are easy to incorporate into the 3D printing process with unmodified consumer-grade technology,” the researchers say. “Although any given design requires some experimentation to be successful, such experimentation is common with non-fabric based prints as well. We are confident that others can easily adopt our techniques to incorporate textiles into their 3D prints.”

The researchers involved in the project were Michael L Rivera, Melissa Moukperian, Daniel Ashbrook, Jennifer Mankoff, and Scott E Hudson. (SV)

Fibre2Fashion News Desk – India

Popular News

Leave your Comments

Editor’s Pick

Ritesh Dodhia

Dodhia Synthetics Limited

Dr. N Mohan

Clarks Reliance Footwear Private Limited

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)