Chemists in US develop simple new method to destroy forever chemicals

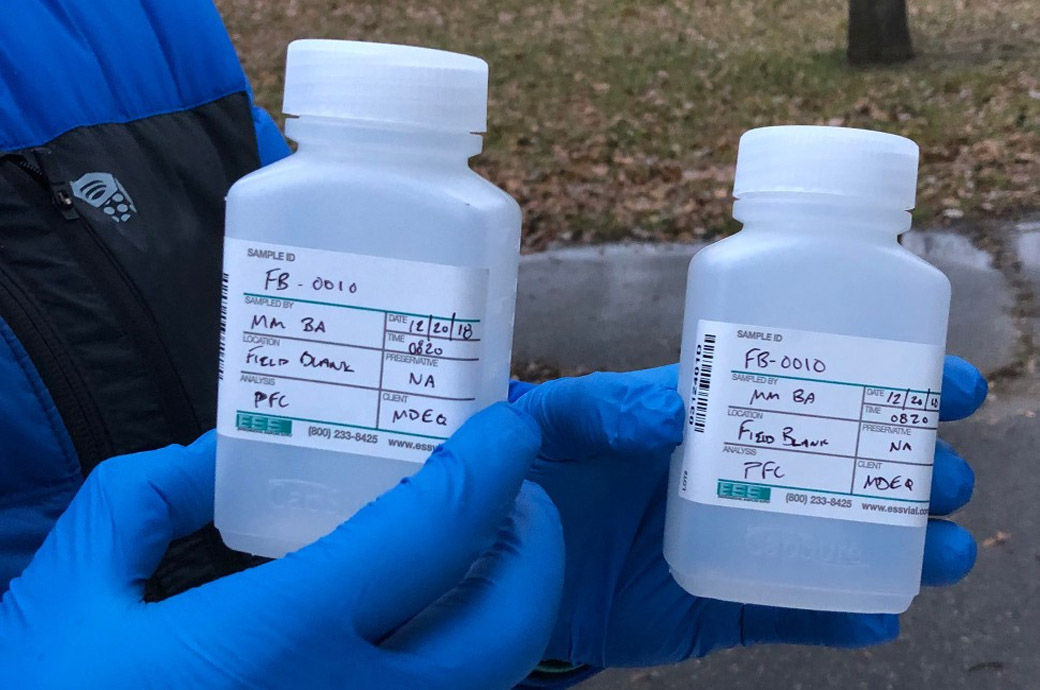

PFAS, short for per- and polyfluoroalkyl substances, are a group of manufactured chemicals commonly used since the 1940s that leach into surrounding soil, becoming a persistent problem for generations to come. These are also referred to as ‘forever chemicals’.

PFAS has been in use for 70 years as nonstick and waterproofing agents. They are commonly found in nonstick cookware, waterproof cosmetics, firefighting foams, water-repellent fabrics and products that resist grease and oil.

PFAS exposure is strongly associated with decreased fertility, developmental effects in children, increased risks of various types of cancer, reduced immunity to fight infections and increased cholesterol levels.

With these adverse health effects in mind, the US Environmental Protection Agency (EPA) recently declared several PFAS as unsafe—even at trace levels.

But, while studying the compounds, the team of William Dichtel, who led the study, found a weakness. PFAS contains a long tail of unyielding carbon-fluorine bonds.

But at one end of the molecule, there is a charged group that often contains charged oxygen atoms. The team targeted this head group by heating the PFAS in dimethyl sulfoxide—an unusual solvent for PFAS destruction—with sodium hydroxide, a common reagent.

The process decapitated the head group, leaving behind a reactive tail, the university said in a press release.

“That triggered all these reactions, and it started spitting out fluorine atoms from these compounds to form fluoride, which is the safest form of fluorine,” Dichtel said. “Although carbon-fluorine bonds are super strong, that charged head group is the Achilles’ heel.”

In previous attempts to destroy PFAS, other researchers have used high temperatures — up to 400 degrees Celsius. Dichtel is excited that the new technique relies on milder conditions and a simple, inexpensive reagent, making the solution potentially more practical for widespread use.

After discovering the PFAS degradation conditions, Dichtel and Trang also discovered that the fluorinated pollutants fall apart by different processes than generally assumed. Using powerful computational methods, team collaborators Ken Houk at UCLA and Yuli Li, a student at Tianjin University who virtually visited Houk’s group, simulated the PFAS degradation.

Their calculations suggest that PFAS falls apart by more complex processes than expected. Although it was previously assumed that PFAS should fall apart one carbon at a time, the simulation showed that PFAS actually falls apart two or three carbons at a time—a discovery that matched Dichtel and Trang’s experiments.

By understanding these pathways, researchers can confirm that only benign products remain. This new knowledge also could help guide further improvements to the method.

The research was published on August 19 in the journal ‘Science’. The study, titled ‘Low-temperature mineralisation of perfluorocarboxylic acids’, was supported by the National Science Foundation.

Dichtel’s team plans to test the effectiveness of its new strategy on other types of PFAS as well. The EPA has identified more than 12,000 PFAS compounds.

Fibre2Fashion News Desk (DS)

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)