Interviews

News Flash

Crystal Group's 4Zero collection scales up digitalisation

19 Nov '20

3 min read

Pic: Crystal International Group

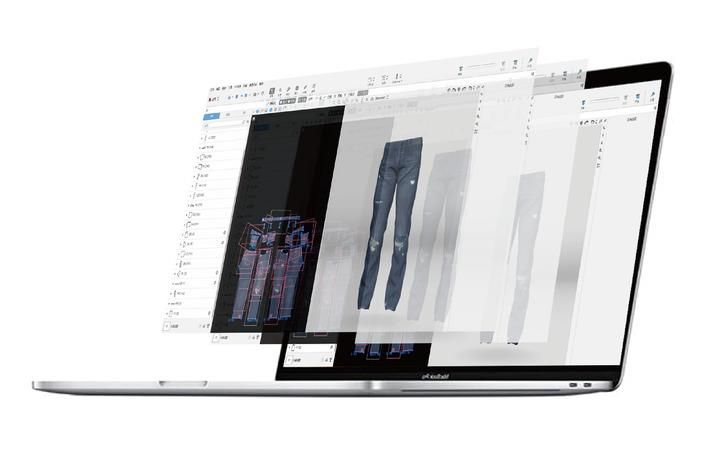

Crystal International Group has advanced digitalised technology and virtual sampling usage driving sustainable product development. In the launch of 4Zero eco collection, Crystal Denim, the denim division of Crystal International, developed its digital showroom for higher transparency of sustainability features and effective communication with stakeholders.

By developing a new digital showroom platform, Crystal Denim shared the latest product information and showcased the full gallery of collection virtually. All customers can track information about fabric, sewing lines and washing units, Environmental Impact Measuring (EIM) score and saving in water and chemical consumption digitally by scanning the QR code on the hangtag of every pair of jeans. Users can also receive seasonal collection inspiration, market news and latest sustainable collection on this one-stop online platform anytime and anywhere.

“With digital innovation, we are more connected than ever. The digital launch of the new 4Zero collection is setting an exceptional example to embody our transparency through product design, material selection and manufacturing processes,” Miles Lam, assistant general manager of product development of Crystal Denim, said in a press release.

The information shown in the digital showroom reveal the sustainability efforts taken throughout the product development, fabric selection and manufacturing process of 4Zero jeans. During the design stage, Crystal Denim embraced digitalisation by creating 3D digital product designs with its own digital library and curating virtual samples. Sustainable fabric for each pair of jeans, which are displayed on the digital platform, are also determined in the design stage. 4Zero collection, which are sewn and washed in the eco denim factory in China, Zhongshan Yida Apparel Ltd adopts sustainable fabric, including 100 per cent Better Cotton Initiative (BCI) cotton, Global Organic Textile Standard (GOTS) organic cotton, recycled materials such as Recycled Claim Standard (RCS) recycled cotton and Repreve recycled materials. With the chain of custody standards, certified materials are traceable along the supply chain.

In addition to the sustainable fabric, 4Zero collection adopts four “Zero” measures in the washing process, including zero manual work, zero potassium permanganate, zero hypochlorite and zero stone for lesser environmental impact while maintaining the worn-out look and the distinctive blue hue of denim. All fabric are tested with great laser reaction, so that zero manual work and zero PP can be achieved with the use of laser. These eco production processes can reduce water usage by up to 90 per cent and chemicals up to 70 per cent when compared with the current conventional eco wash method. All jeans in the collection scored “low impact” (the best impact category) at EIM tool, which calculates the environmental impact of water consumption, energy consumption, chemical consumption and impact on workers’ health. With these cleaner finishing approaches, 4Zero collection serves as another sustainable choice for customers.

Crystal International will continue to be at the forefront of sustainable denim manufacturing by bringing the best sustainability practices to the market.

Fibre2Fashion News Desk (JL)

Popular News

Leave your Comments

Editor’s Pick

Folker Stachetzki

Brother Internationale Industriemaschinen GmbH

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)