Global new textile machinery shipments increased in 2017

Shipments of new electronic flat knitting machines and finishing machines of the category ‘fabric discontinuous’ each rose by 44 per cent year-on-year. In contrast, deliveries of circular knitting machines stagnated in 2017 (+0.12 per cent) and finishing machines of the category ‘fabrics continuous’ fell by 2 per cent, ITMF said in the 40th annual International Textile Machinery Shipment Statistics (ITMSS).

The report covers six segments of textile machinery, namely spinning, draw-texturing, weaving, large circular knitting, flat knitting and finishing. The 2017 survey has been compiled in cooperation with more than 200 textile machinery manufacturers representing a comprehensive measure of world production. This number includes numerous Chinese companies represented by the so-called ‘District’, ITMF said in a statement.

In spinning machinery, shipments of new short-staple spindles increased for the first time since 2013. The level of short-staple spindles improved by about 1.65 million spindles. Most of the new short-staple spindles (95 per cent) were shipped to Asia, whereby shipments rose by almost 24 per cent year-on-year. Thereby China, the world’s largest investor of short-staple spindles, experienced an increase of 34 per cent, whereas deliveries to Bangladesh and Vietnam decreased by 33 per cent and 39 per cent, respectively. Shipments to Indonesia strongly increased last year (+ 135 per cent). The six largest investors in the short-staple segment in 2017 where China, India, Uzbekistan, Bangladesh, Pakistan, and Indonesia.

In texturing machinery, global shipments of double heater draw-texturing spindles (mainly used for polyester filaments) the downward trend ended and global shipments increased by 27 per cent on an annual basis to about 340,000 spindles. Asia’s share of worldwide shipments amounted to 90 per cent. Thereby, China remained the largest investor accounting for 66 per cent of global shipments, the report said.

In weaving machinery segment, 2017 worldwide shipments of shuttle-less looms increased by 12 per cent to 95,400 units. Thereby, shipments of air-jet, water-jet, and rapier/projectile shuttle-less looms increased by 18 per cent (to almost 27,000), 14 per cent (to 36,200), and 7 per cent (to 32,000), respectively. Not surprisingly, the main destination of shipments of all shuttle-less looms (air-jet, water-jet and rapier/projectile) in 2017 was Asia with 91 per cent of worldwide deliveries.

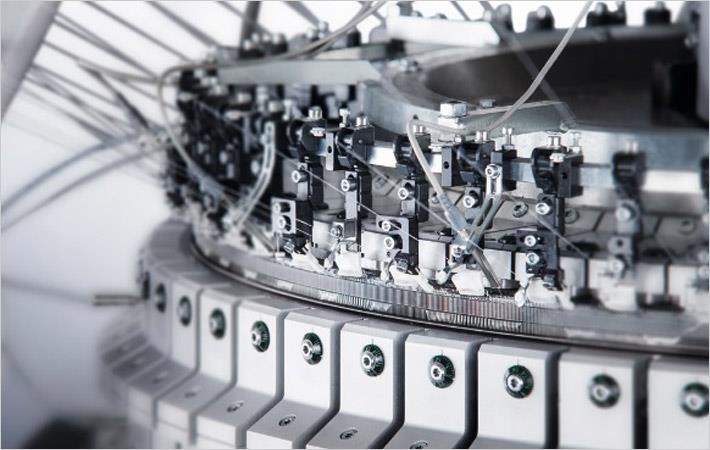

Global shipments of large circular knitting machines rose slightly by 0.12 per cent to a level close to 28,000 units in 2017. Asia is also the world’s leading investor in this category. 84 per cent of all new circular knitting machines were shipped to Asia in 2017. With 39 per cent of worldwide deliveries, China was the single largest investor. India and Vietnam ranked second and third with 5,100 and 2,000 units, respectively, according to ITMSS.

In 2017 the segment of electronic flat knitting machines soared by 44 per cent to around 202,000 machines, the highest level ever. Not surprisingly, Asia received the highest share of shipments (96 per cent). China remained by far the world’s largest investor for flat knitting machines in 2017. Thereby, Chinese investments increased from 101,550 units to 154,850 and the country had a global share of 76 per cent.

In the segment of fabrics continuous (finishing machinery), shipments of mercerising-lines, singeing-lines, and stenters, increased in 2017 by 54 per cent, 11 per cent, and 2 per cent, respectively. Deliveries in the other sub-segments decreased. In the segment fabrics discontinuous, shipments of air-jet dyeing and overflow dyeing machines increased by 35 per cent and 72 per cent, respectively, whereas those of jigger dyeing/ beam dyeing machines fell by 7 per cent. (RKS)

Fibre2Fashion News Desk – India

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)