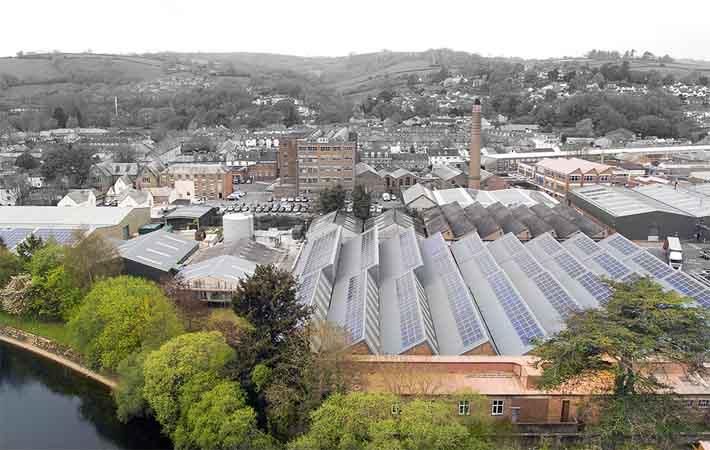

Heathcoat Fabrics completes installation of solar panels

Focusing on using renewable and efficient energy practices, the local manufacturer introduced over 2,200 solar panels, a sophisticated hydro generation scheme and a new state-of-the-art 2MWh Combined Heat and Power (CHP) engine and combination boiler. Implementing the three projects has already lead to a significant 60 per cent reduction in the amount of energy previously imported from the national grid.

The CHP engine operates by transforming gas into electricity at less than half the cost of imported electricity supplied by the national grid. The benefit of using a CHP engine is that the exhaust heat produced during the conversion process isn't released directly back into the atmosphere. Instead, the exhaust heat is recovered and sent to the combination boiler which boils water to generate steam and heat that is used within the factory dye house and the technical automotive fabrics processing area.

"We have been working on ways to determine the best methods of practice to ultimately do our part in achieving a low carbon future. The installation of the solar panels was the first project we completed where we installed 2,225 solar panels on the roofing of five production sheds. The solar panel system was a stepping stone towards bigger scale projects to improve the sustainability of the business," business project manager, Alison Kitchener, said.

The most recent of the three installations was the reintroduction of a hydro generation scheme. The energy derived from consistent water flow is captured and converted into electricity, generating enough electricity to supply power to the main office and its research and development testing laboratories.

"As a business surrounded by such a beautiful landscape, we decided it was imperative for Heathcoat Fabrics to look at ways in which we could operate in a more environmentally friendly and cost-effective way," Cameron Harvie, managing director at Heathcoat Fabrics, said.

"Our aim is to ensure we are doing our part to keep Devon green, by showing our industry, community and staff that we're actively finding ways to invest in our future by reducing our carbon footprint. Implementing ways of utilising renewable energy sources is a start and these changes will help contribute towards national and international climate change targets," concluded Harvie. (RR)

Fibre2Fashion News Desk – India

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)